Degassing and deodorizing method for acetylene apparatus carbon black water

An acetylene device, degassing and deodorizing technology, applied in the field of natural gas, can solve the problems of inability to meet environmental protection standards, small overall process impact, insufficient contact, etc., and achieve the effect of significant removal effect, small process impact, and low consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

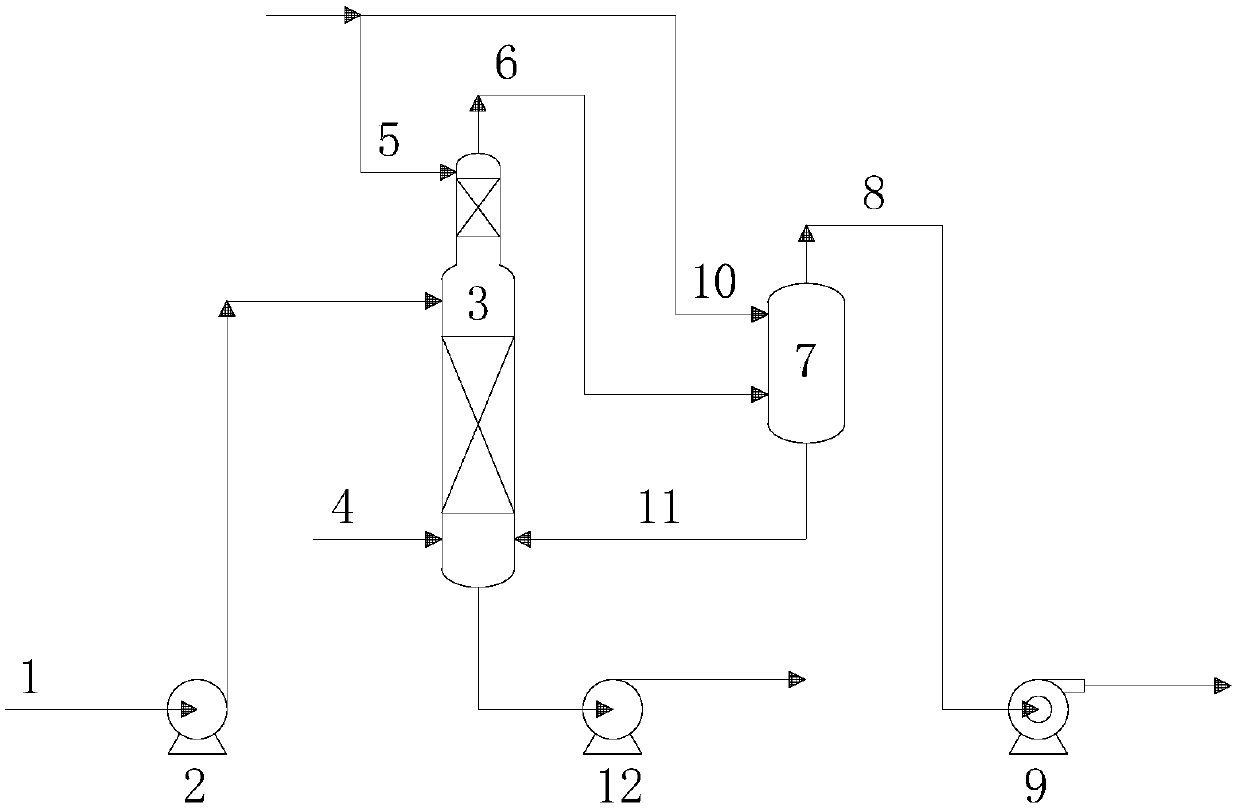

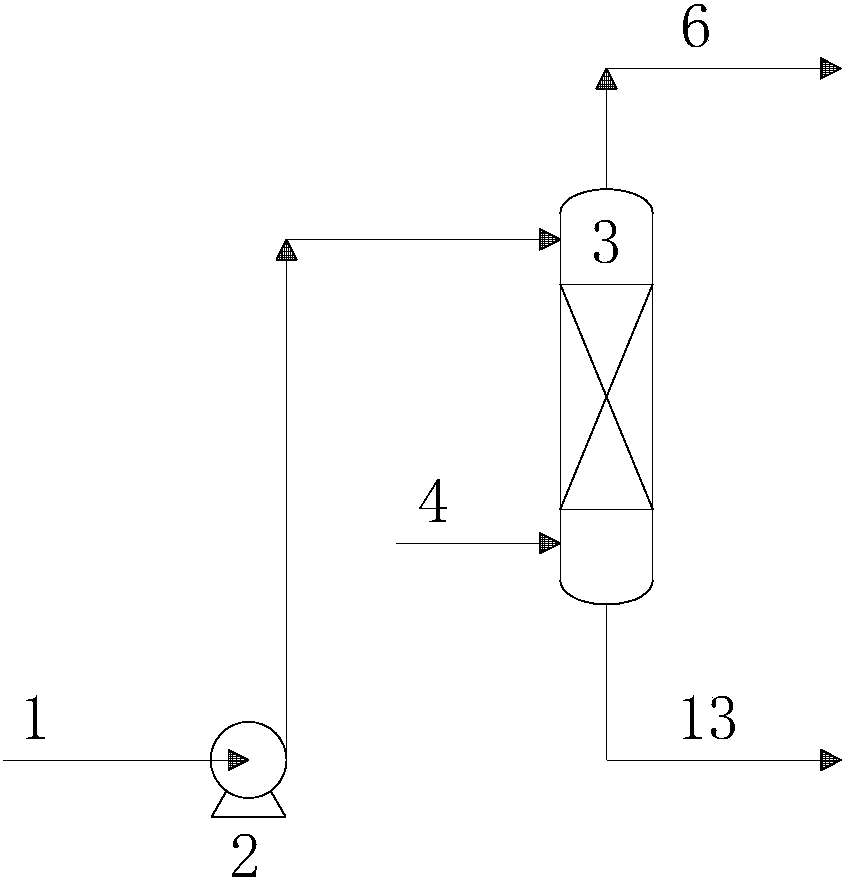

[0039] Combine the following figure 1 An embodiment of the present invention is explained.

[0040] Acetylene plant to be treated carbon black water 1 properties and composition: temperature 78 ℃, pressure 0.005MPa (gauge pressure), flow 300t / h, carbon black content 0.2g / L, cracked gas total content 0.0034wt%, wherein content is higher ( >0.0001wt%) components include carbon monoxide (0.00027wt%), acetylene (0.00254wt%) and diacetylene (0.00037wt%), and the unit wt% refers to mass percentage.

[0041] The nature and composition of the enriched tail gas 4 from the enrichment section of the acetylene plant: the temperature is 15°C, the pressure is 0.09MPa (gauge pressure), and the components with relatively high content (>4v%) are hydrogen (61.68v%), carbon monoxide (27.18v%) %), methane (4.91v%) and other components such as a small amount of acetylene (0.04v%), and the unit v% refers to volume percentage.

[0042] Such as figure 1 Shown, the degassing and deodorizing impleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com