Preparation method and application of silicon dioxide/biochar composite material

A technology of silica and composite materials, which is applied in nanotechnology, electrochemical generators, secondary batteries, etc. for materials and surface science, can solve the problems of conversion reaction volume expansion, etc., and achieve high cycle specific capacity, effective Good for large-scale preparation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

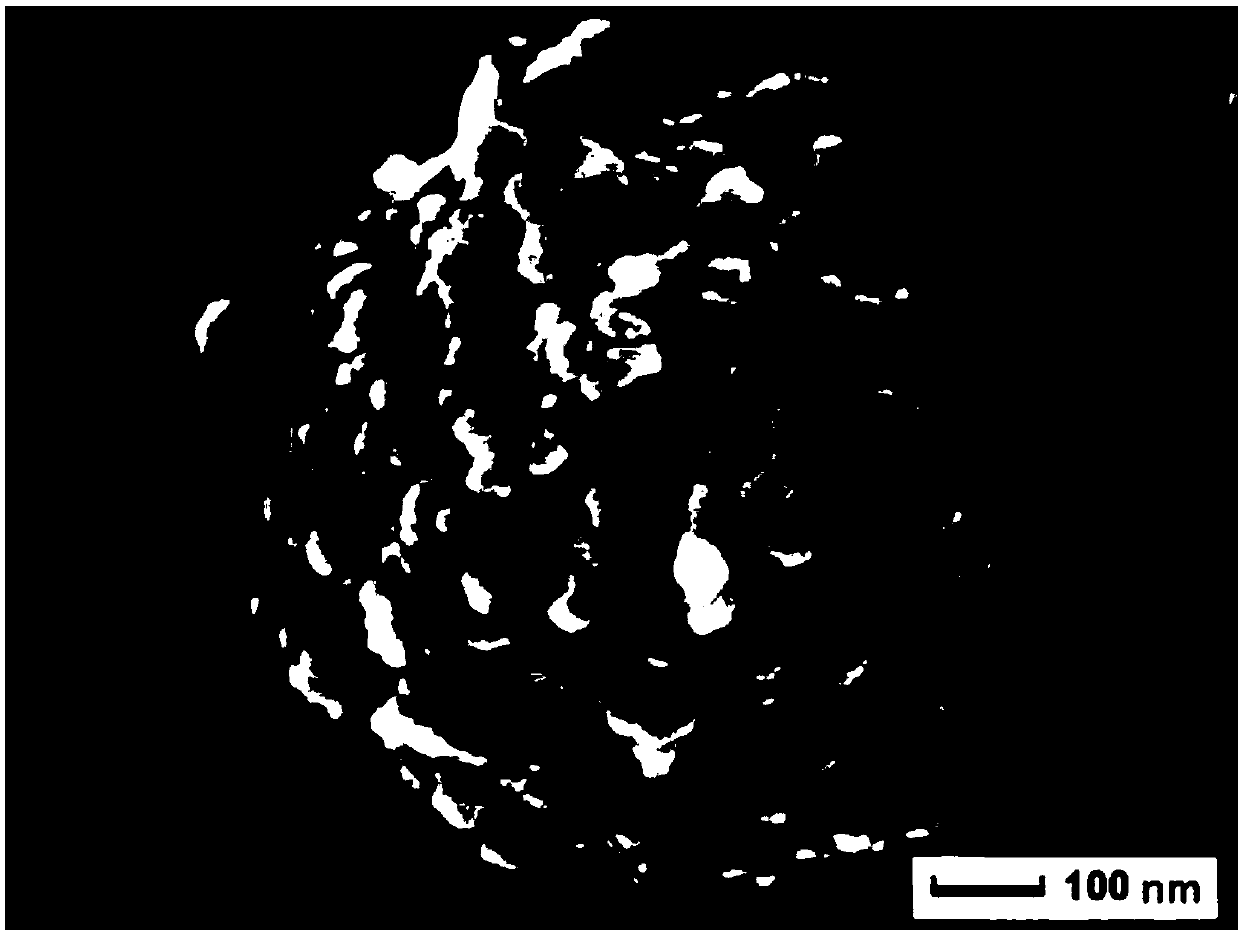

[0030] A preparation method of silicon dioxide / biochar composite lithium-ion battery negative electrode material, comprising the steps of:

[0031] Step 1: Take out an egg yolk, put it in a beaker and stir it mechanically (the speed is controlled at 500r min throughout the process) -1 ) under the action of adding water and ethanol in order to dilute (water and ethanol were added 50-100mL, and the volume ratio was controlled at 1:1), and after stirring for 15min, 2-6mL (2mL, 3mL, 6mL) ammonia water was added dropwise to Provide an alkaline environment, then add 2-6mLTEOS (2mL, 3mL, 4mL, 5mL, 6mL) dropwise, keep stirring at room temperature for 3-12h (3h, 6h, 12h), and finally freeze the obtained light yellow viscous liquid Drying gave an intermediate product.

[0032] Step 2: Get 0.5g of the intermediate obtained in step 1 and put it into a crucible, put the crucible into a tube furnace, and feed 5% hydrogen-argon gas mixture into the tube furnace (nitrogen, argon, helium, A ...

Embodiment 1

[0038] Take out the yolk of an egg and put it in a beaker, at 500r min -1 Under the action of mechanical stirring, add 35mL water and 35mL ethanol next time, after stirring for 15min, add 3mL ammonia water with a mass fraction of 25-28% dropwise, and then add 4mLTEOS dropwise, and keep stirring at room temperature for 3h after the dropwise addition.

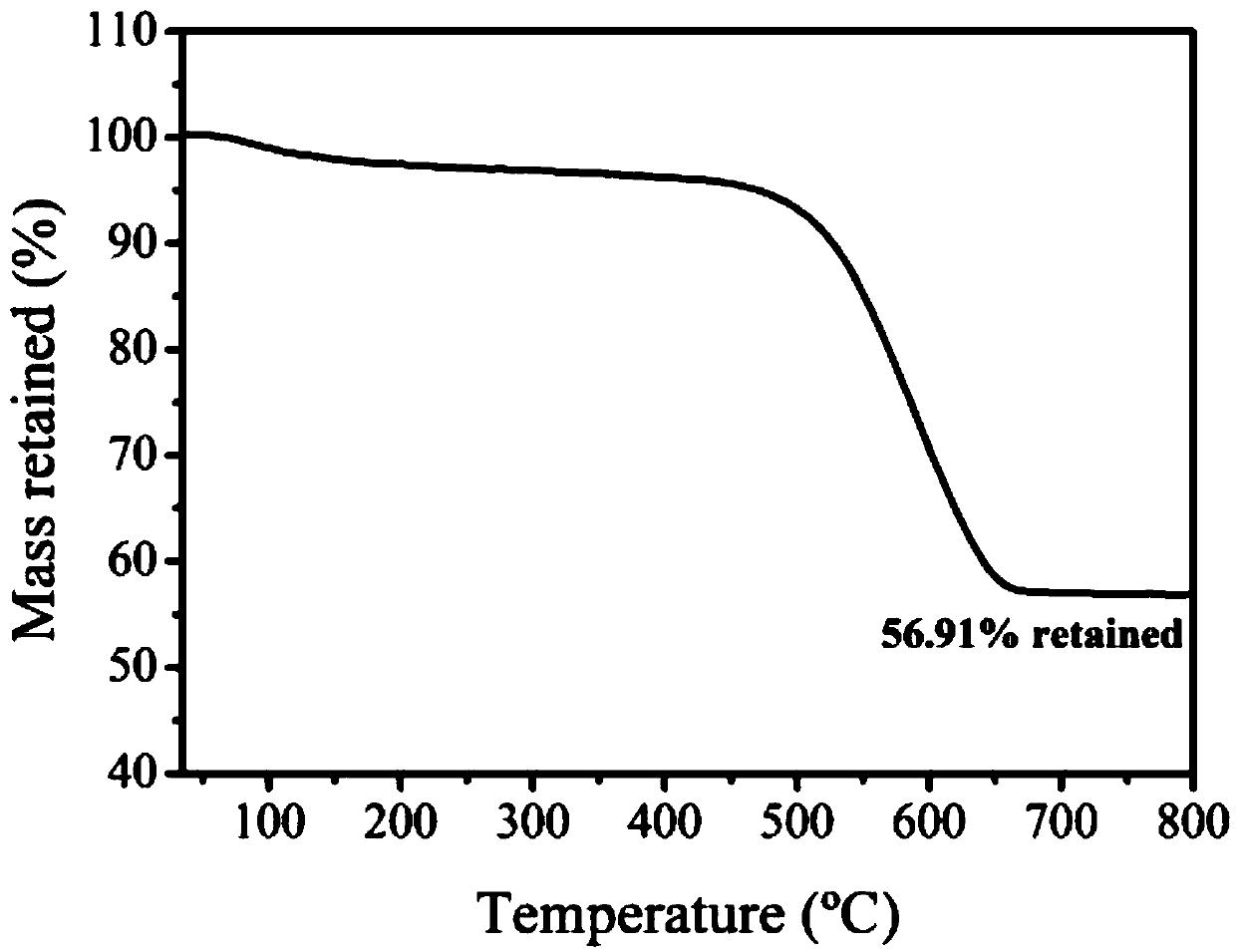

[0039]The obtained pale yellow viscous liquid was freeze-dried for 24 hours, weighed 0.5 g of the precursor, put it into a crucible, and calcined it in a tube furnace with a mixed atmosphere of hydrogen and argon. The heating rate was set at 5 °C min -1 , the calcination temperature was 800°C, and the calcination time was 4h to obtain a silica / biochar composite material.

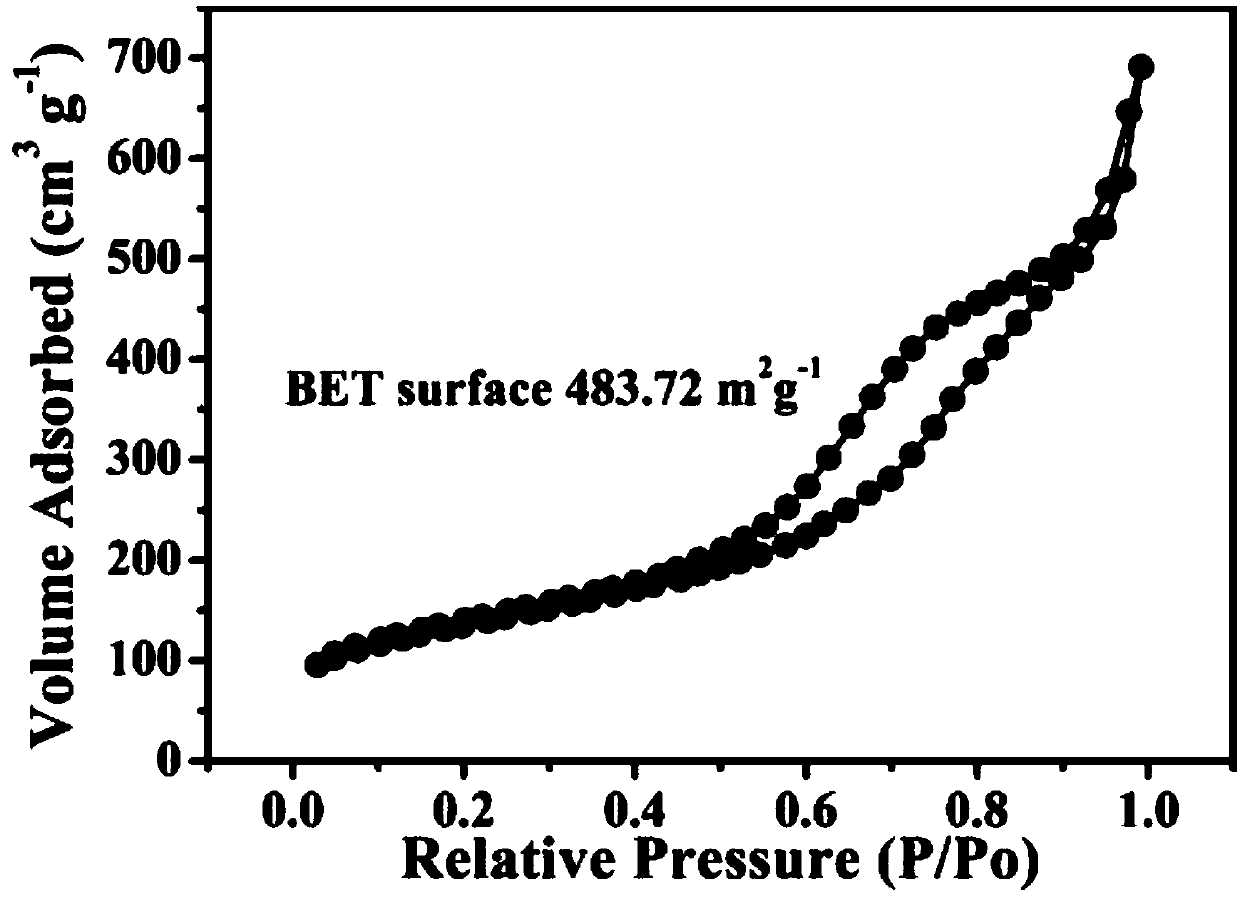

[0040] The black powder obtained by calcining was mixed with 4mL 0.1g mL -1 Diluted with NaOH to 100mL and soaked for 12 to obtain a porous structure, after centrifugation, washed with water and ethanol three times respectively, and dried in a vacuum oven at 8...

Embodiment 2

[0045] Take out the yolk of an egg and put it in a beaker, at 500r min -1 Under the action of mechanical stirring, add 35mL water and 35mL ethanol at a time. After stirring for 15min, add 3mL concentrated ammonia water dropwise, and then add 4mL TEOS dropwise. After the dropwise addition, keep stirring at room temperature for 6h.

[0046] The obtained pale yellow viscous liquid was freeze-dried for 24 hours, weighed 0.5 g of the precursor, put it into a crucible, and calcined it in a tube furnace with a mixed atmosphere of hydrogen and argon. The heating rate was set at 5 °C min -1 , the calcination temperature was 800°C, and the calcination time was 4h to obtain a silica / biochar composite material.

[0047] The black powder obtained by calcining was mixed with 4mL 0.1g mL -1 The KOH was diluted to 100mL and soaked for 12 hours to obtain a porous structure. After centrifugation, it was washed three times with water and ethanol and placed in a vacuum oven at 80°C for 8 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Reversible specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com