Fireproof layer material and its preparation method and fireproof glass

A technology for fireproof glass and fireproof layer, which is applied to fireproof layer materials and their preparation, and the field of fireproof glass, can solve the problems of a large number of micro-bubbles, poor low temperature resistance and poor apparent quality in the glass interlayer, and achieve good adhesion and improved strength. , the effect of eliminating bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The present invention also proposes a preparation method of fireproof layer material, which comprises the following steps:

[0070] (1) Add 50-300 parts by weight of organic / inorganic hybrid particles with hydrophilic nano-core-shell structure to 50-200 parts by weight of deionized water, and stir evenly to obtain the first solution; wherein, the hydrophilic nano-core The organic / inorganic hybrid particles with shell structure are wide-distributed nanoparticles, the core material is gas phase nano-silica particles and their aggregates, and the shell material is poly(methacrylic acid-acrylic acid-acrylamide-styrene) copolymer thing;

[0071] (2) Under stirring conditions, add 5-200 parts by weight of anti-condensation agent, 0.5-6 parts by weight of char-forming agent, 0.5-6 parts by weight of char-forming aid, 0.5-6 parts by weight of Heat-resistant stabilizer, 0.05-1 parts by weight ion fixative, 0.3-1.2 parts by weight storage stabilizer, 0.1-0.4 parts by weight defo...

Embodiment 1

[0093]This embodiment provides a method for preparing a fireproof layer material, which specifically includes the following steps:

[0094] (1) Weigh the raw materials of fireproof layer materials according to the following weights:

[0095] 100kg of hydrophilic nano-core-shell structure organic / inorganic hybrid particles with a particle size of 80-6000nm, 85kg of deionized water, 15kg of ethylene glycol, 1kg of sucrose, 1kg of potassium dihydrogen phosphate, 0.5kg of borax, 0.5kg of boric acid, 0.3 kg alumina, 0.4kg polyphosphate, 0.1kg defoamer BYK-024, 0.5kg sodium fluorosilicate and 90kg 50% potassium hydroxide aqueous solution; due to the hydrophilic nano-core-shell structure organic The particle diameter of / inorganic hybrid particle is wide distribution, and the nuclei particle of various particle diameter size all can exist in the present invention, as Figure 5 Shown, is the SiO of the hydrophilic nano-core-shell structure organic / inorganic hybrid particle of the pres...

Embodiment 2

[0115] This embodiment provides a method for preparing a fireproof layer material, which specifically includes the following steps:

[0116] (1) Weigh the raw materials of fireproof layer materials according to the following weights:

[0117] 100kg of hydrophilic nano core-shell structure organic / inorganic hybrid particles with a particle size of 80nm-6000nm, 80kg of deionized water, 20kg of ethylene glycol, 1kg of sucrose, 1kg of potassium dihydrogen phosphate, 0.5kg of borax, 0.5kg of boric acid, 0.3 kg alumina, 0.4kg polyphosphate, 0.1kg defoamer BYK-024, 0.5kg sodium fluorosilicate and 90kg mass percent concentration of 50% potassium hydroxide aqueous solution;

[0118] (2) The above-mentioned raw materials were prepared according to the same preparation method as in Example 1 to prepare the fireproof layer material.

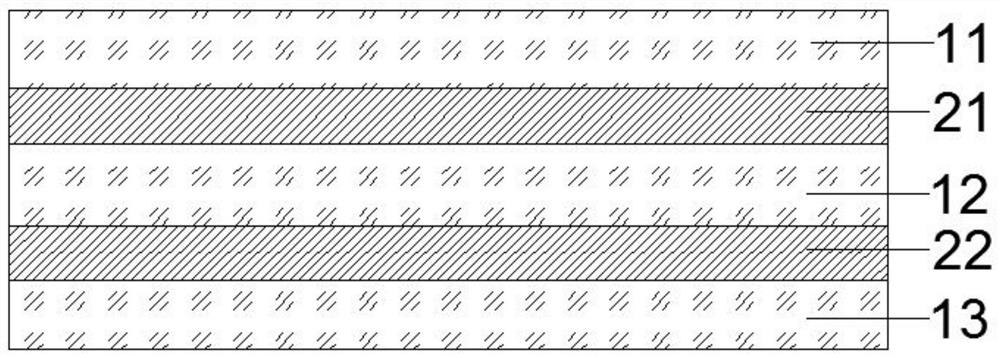

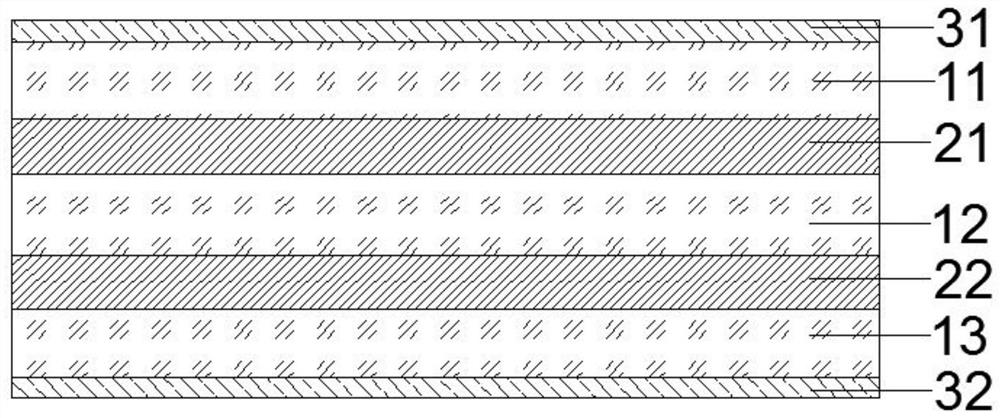

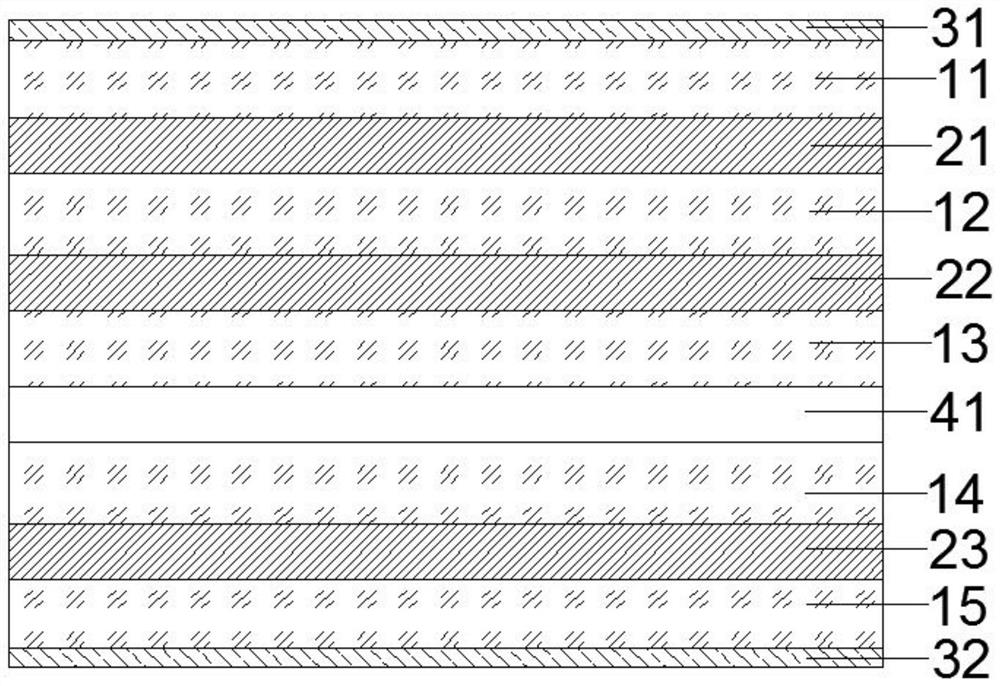

[0119] The embodiment of the present invention also provides a method for preparing fire-resistant glass using the above-mentioned fire-resistant layer mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com