Preparation method for modifying high nickel ternary positive electrode material through multi-component coating

A positive electrode material and high-nickel technology, which is applied in the field of preparation of high-nickel ternary positive electrode materials modified by multiple coatings, can solve problems such as complex coating modification process, achieve safety and cycle improvement, complete structure, Improves the effect of free lithium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

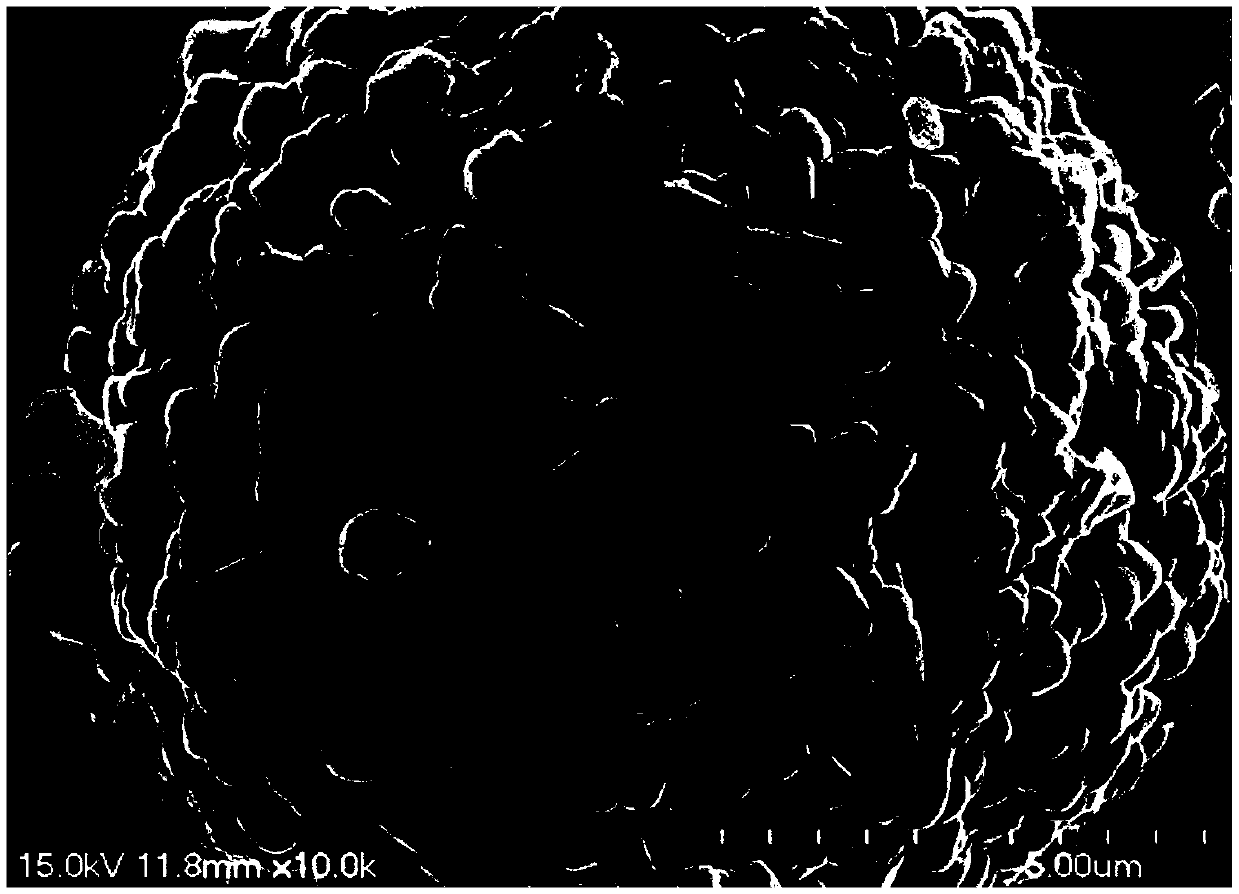

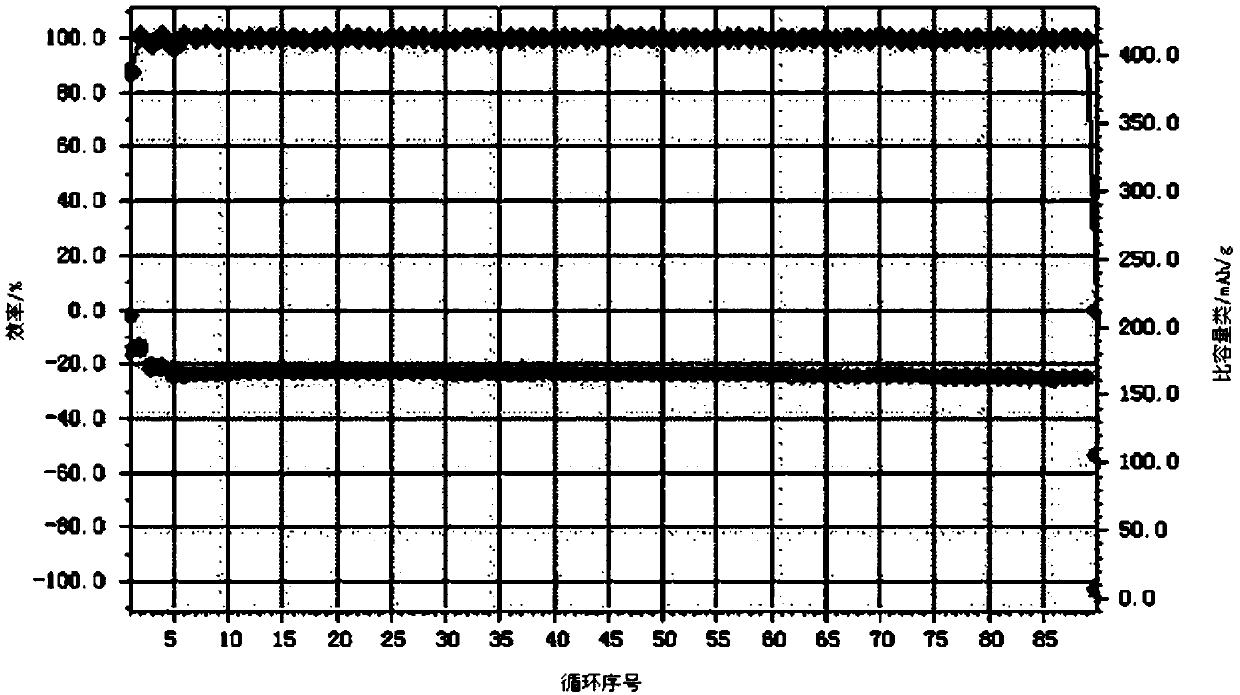

[0021] In this example, the high-nickel ternary cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 It is 5kg of matrix, mixed with 9.4g of nano-alumina and 24.2g of nano-sized boron oxide, put it into a high-speed mixer and mix evenly, mix at 150rpm for 30 minutes, and then take it out. Put the mixed material into the atmosphere type resistance furnace for low temperature sintering, raise it to 680°C in 1.5 hours, keep it warm for 10 hours, and give the oxygen amount of 0.8m 3 / h. After natural cooling, it was taken out and passed through a 325-mesh sieve to obtain product 1. Do SEM scanning electron microscope (see figure 1 ); At the same time, the half-cell performance test (2.75-4.3V) of the product is carried out at a rate of 0.5C (see figure 2 ).

example 2

[0023] In this example, the high-nickel ternary cathode material LiNi 0.6 co 0.1 mn 0.3 o 2 5kg of the matrix is mixed with 9.4g of nano-sized alumina and 42.8g of nano-sized boric acid, put into a planetary ball mill and mix evenly, and take it out after mixing at 300rpm for 5 minutes. Put the mixed material into the atmosphere type resistance furnace for low temperature sintering, raise it to 660°C in 1.5 hours, keep it warm for 10 hours, and give 0.8m oxygen 3 / h. After natural cooling, it was taken out and passed through a 325-mesh sieve to obtain a modified high-nickel positive electrode material.

example 3

[0025] In this example, the high-nickel ternary cathode material LiNi 0.7 co 0.1 mn 0.2 o 2 5 kg of the base, with 14.4 g of nano-sized aluminum hydroxide and 42.8 g of nano-sized boric acid, put into the oblique mixer and mix evenly, and take it out after mixing at 50 rpm for 60 minutes. Put the mixed material into the atmosphere type resistance furnace for low temperature sintering, raise it to 500°C in 1.5 hours, keep it warm for 10 hours, and give 1.2m oxygen 3 / h. After natural cooling, it was taken out and passed through a 325-mesh sieve to obtain a modified high-nickel positive electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com