Initially sprouted triticale whole flour stuffing and preparing method thereof

A wheat and filling technology, applied in baking, baked food, food science and other directions, can solve the problems of easy hardening of fillings, high regeneration value, and loose fillings, so as to achieve delicate and soft taste, moderate hardness, Flavorful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

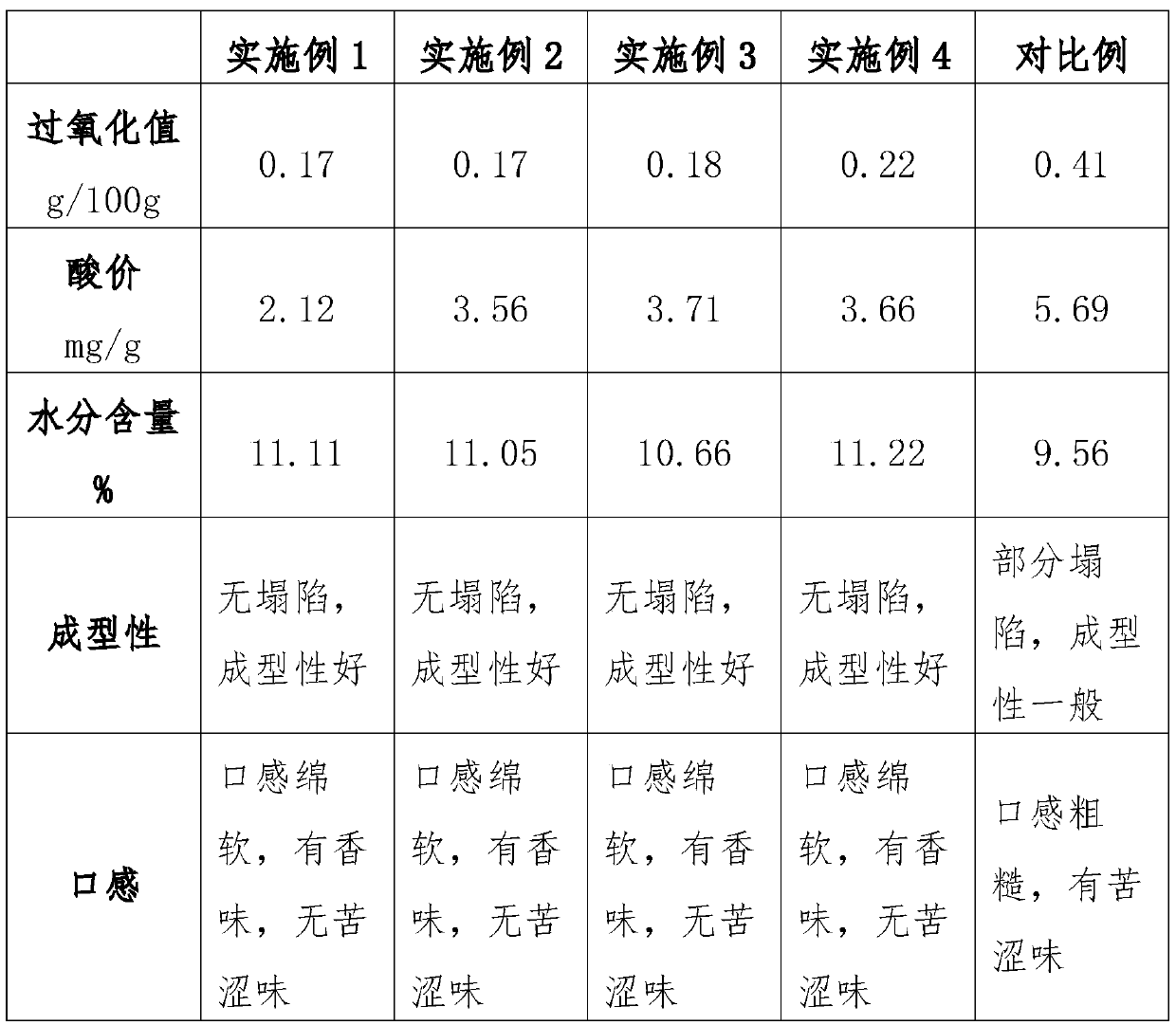

Examples

Embodiment 1

[0025] 1. Making the stuffing

[0026] (1) Disinfect the triticale seeds with 10% sodium hypochlorite for 12 minutes, then rinse them with distilled water for 3 times, spread the seeds on a porcelain plate covered with a wet towel, and germinate for 2-3 days in a germination box at 25°C. It is advisable for the teeth to have just erupted;

[0027] (2) cleaning the germinated seeds, placing them in an oven to dry, and then pulverizing to make germinated triticale whole flour;

[0028] (3) Stir 950g of germinating triticale whole flour and 180g of oat flour evenly;

[0029] (4) Heat 700g of salad oil, pour the flour evenly stirred in step (3) into the oil, fry until cooked, pour out and cool to room temperature;

[0030] (5) Add 950g purple sweet potato puree, 300g fructose syrup, 15g honey, 1g pectin, 350g white sugar, 70g diced tomato, 60g raisin, 90g cranberry, 80g diced orange, 180g pine nut kernel, 200g oat kernel, 180g Pumpkin seeds, 60g of rose petals soaked in wine, 9...

Embodiment 2

[0048] 1. Making the stuffing

[0049](1) Disinfect the triticale seeds with 10% sodium hypochlorite for 12 minutes, then rinse them with distilled water for 3 times, spread the seeds on a porcelain plate covered with a wet towel, and germinate for 2-3 days in a germination box at 25°C. It is advisable for the teeth to have just erupted;

[0050] (2) cleaning the germinated seeds, placing them in an oven to dry, and then pulverizing to make germinated triticale whole flour;

[0051] (3) Stir 1100g sprouted triticale whole flour and 220g oat flour evenly;

[0052] (4) Heat 650g of salad oil, pour the flour evenly stirred in step (3) into the oil, fry until cooked, pour out and cool to room temperature;

[0053] (5) Add 1100g purple sweet potato puree, 350g fructose syrup, 25g honey, 2g pectin, 400g white sugar, 90g diced tomato, 65g raisin, 100g cranberry, 100g diced orange, 190g pine nut kernel, 150g oat kernel, 190g Pumpkin seeds, 45g of rose petals soaked in wine, 70g of ...

Embodiment 3

[0056] 1. Making the stuffing

[0057] (1) Disinfect the triticale seeds with 10% sodium hypochlorite for 12 minutes, then rinse them with distilled water for 3 times, spread the seeds on a porcelain plate covered with a wet towel, and germinate for 2-3 days in a germination box at 25°C. It is advisable for the teeth to have just erupted;

[0058] (2) cleaning the germinated seeds, placing them in an oven to dry, and then pulverizing to make germinated triticale whole flour;

[0059] (3) Stir 1000g sprouted triticale whole flour and 200g oat flour evenly;

[0060] (4) Heat 750g of salad oil, pour the flour evenly stirred in step (3) into the oil, fry until cooked, pour out and cool to room temperature;

[0061] (5) Add 1000g purple sweet potato puree, 280g fructose syrup, 20g honey, 1.5g pectin, 410g white sugar, 80g diced tomato, 75g raisins, 95g cranberry, 90g diced orange, 200g pine nuts, 160g oatmeal, 210g of pumpkin seeds, 50g of rose petals soaked in wine, 80g of wine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com