Catalyst composition and application of same

A composition and catalyst technology, applied in the direction of hydrocarbons, hydrocarbons, physical/chemical process catalysts, etc., can solve the problems of aromatic hydrocarbon residues, affecting product quality, etc., and achieve high activity, low cost, and high selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

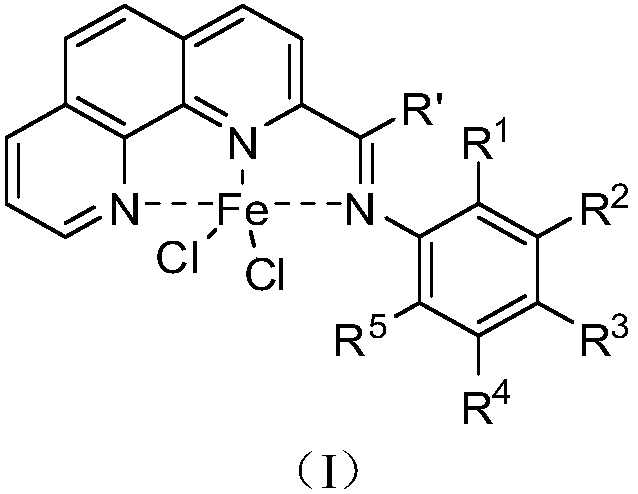

Method used

Image

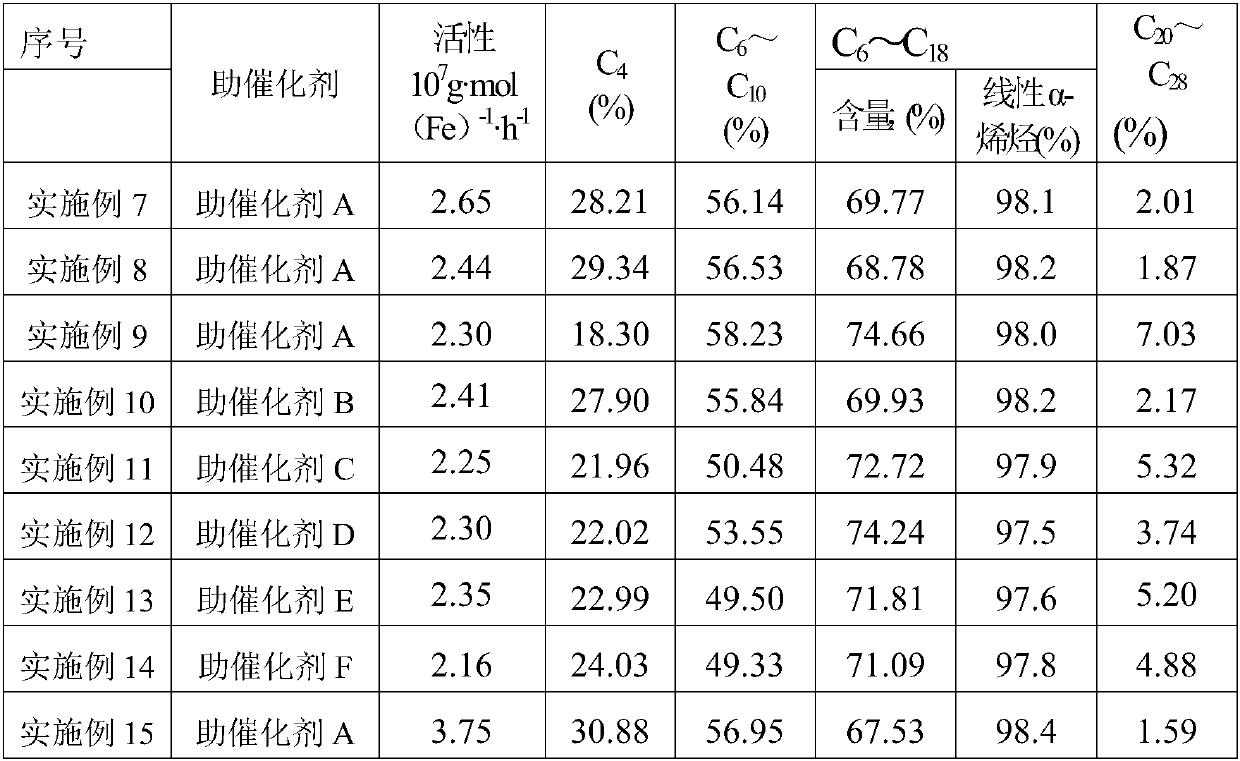

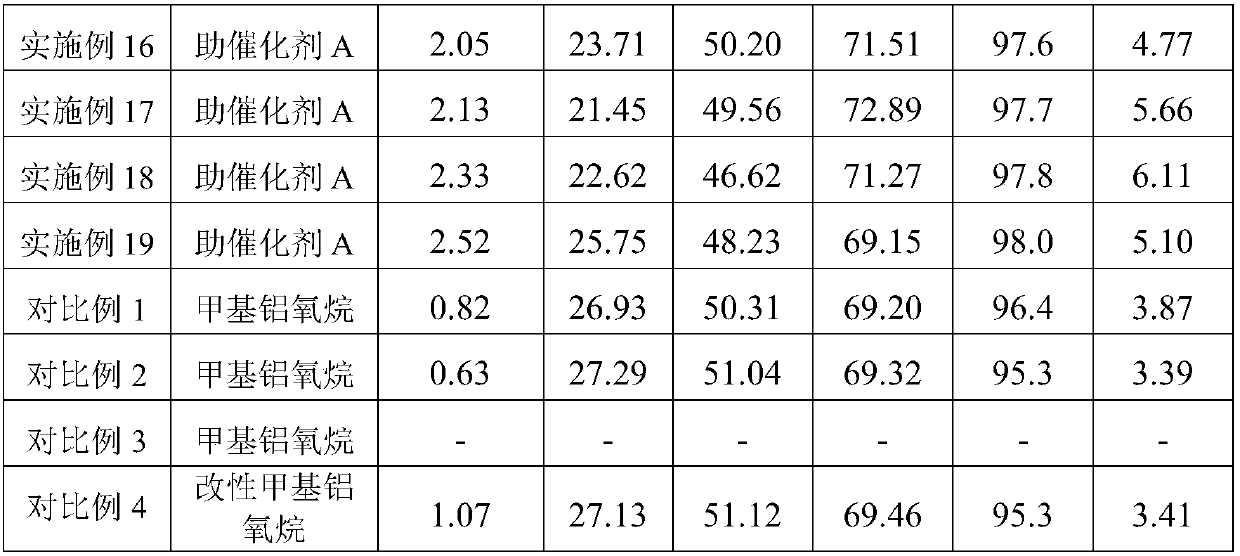

Examples

Embodiment 1

[0046] Under the protection of nitrogen, slowly add 7 mmol of water dropwise to 10 mmol of triisobutylaluminum (1M toluene solution) in an ice bath, stir and react for 0.5 hours, then raise the temperature and reflux for 1 hour, then lower it to room temperature for later use; take 10 mmol of methyl aluminum oxide Alkane (1M toluene solution) was added to the above solution, then heated to reflux for 1 hour, and then lowered to room temperature; 2 mmol of water was slowly added to the above mixed solution in an ice bath, and after stirring for 0.5 hours, heated to reflux for 1 hour, and then Cool down to room temperature, remove the toluene solvent under reduced pressure, then add heptane solvent, the total volume of the mixed solution is 20 mL, and obtain cocatalyst A (1M, heptane solution).

[0047] Product analysis: take the quantitative cocatalyst A, slowly add excess water to decompose it, the aluminum content of the liquid phase component is 3.4wt% by ICP test; the isobut...

Embodiment 2

[0049] Under the protection of nitrogen, slowly add 5 mmol of water dropwise to 10 mmol of triisobutylaluminum (1M toluene solution) in an ice bath, stir and react for 0.5 hours, then raise the temperature and reflux for 1 hour, then lower it to room temperature for later use; take 10 mmol of methyl aluminum oxide Alkane (1M toluene solution) was added to the above solution, then heated to reflux for 1 hour, and then lowered to room temperature; 2 mmol of water was slowly added to the above mixed solution in an ice bath, and after stirring for 0.5 hours, heated to reflux for 1 hour, and then Cool down to room temperature, remove the toluene solvent under reduced pressure, then add heptane solvent, the total volume of the mixed solution is 20mL, and obtain cocatalyst B (1M, heptane solution).

[0050] Product analysis: get quantitative (with embodiment 1) cocatalyst B, slowly add excessive water and make it decompose, liquid phase component is 3.4wt% with ICP test aluminum conte...

Embodiment 3

[0052] Under the protection of nitrogen, slowly add 10 mmol of water dropwise to 10 mmol of triisobutylaluminum (1M toluene solution) in an ice bath, stir and react for 0.5 hours, then raise the temperature and reflux for 1 hour, and then lower it to room temperature for later use; take 10 mmol of methyl aluminum oxide Alkane (1M toluene solution) was added to the above solution, then heated to reflux for 1 hour, and then lowered to room temperature; 2 mmol of water was slowly added to the above mixed solution in an ice bath, and after stirring for 0.5 hours, heated to reflux for 1 hour, and then Cool down to room temperature, remove the toluene solvent under reduced pressure, then add heptane solvent, the total volume of the mixed solution is 20 mL, and obtain cocatalyst C (1M, heptane solution).

[0053] Product analysis: get quantitative (with embodiment 1) cocatalyst C, slowly add excessive water and make it decompose, liquid phase component is 3.4wt% with ICP test aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com