Manufacturing method of heat-insulating glass for solar power generation

A technology of insulating glass and a manufacturing method, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric devices that only utilize the Peltier or Seebeck effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

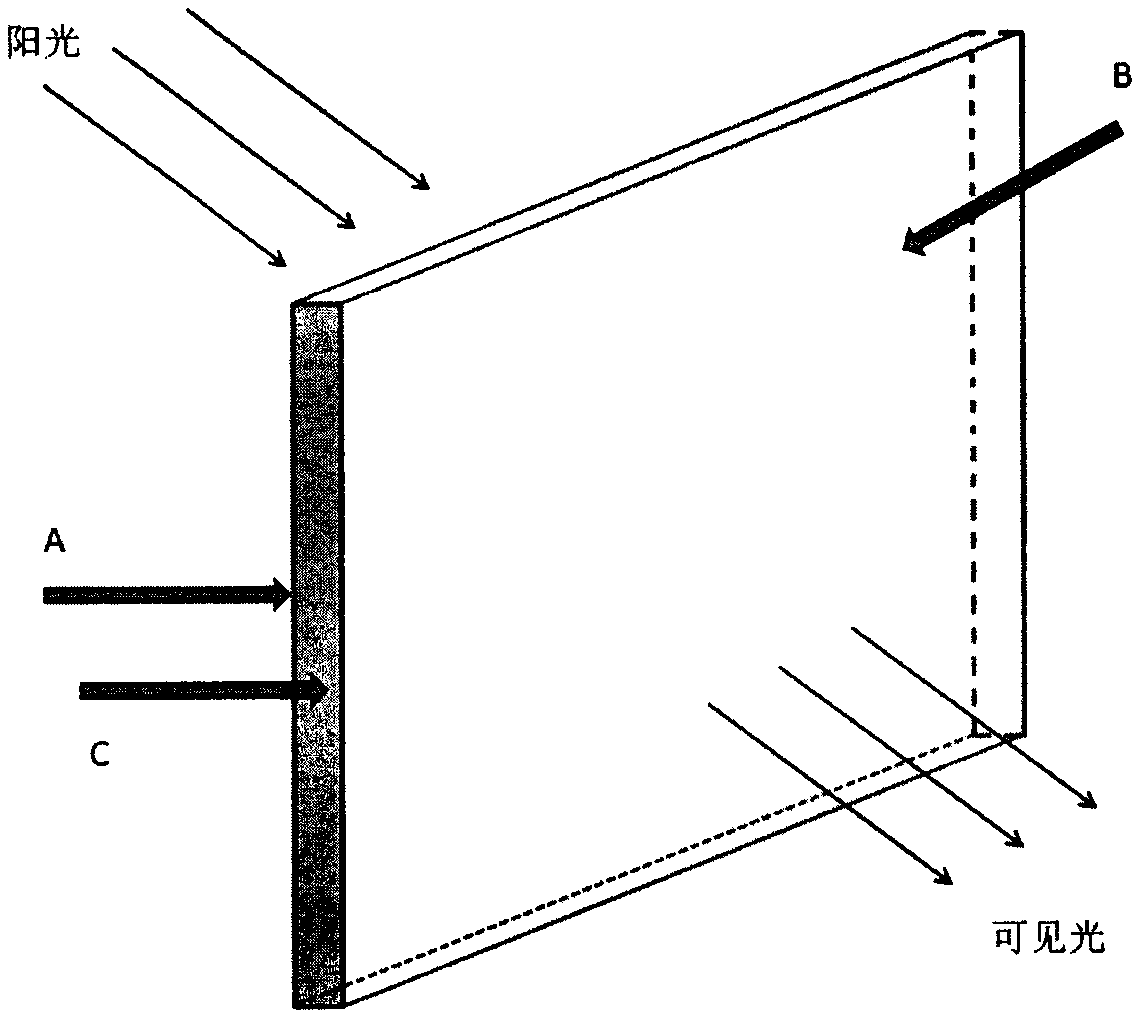

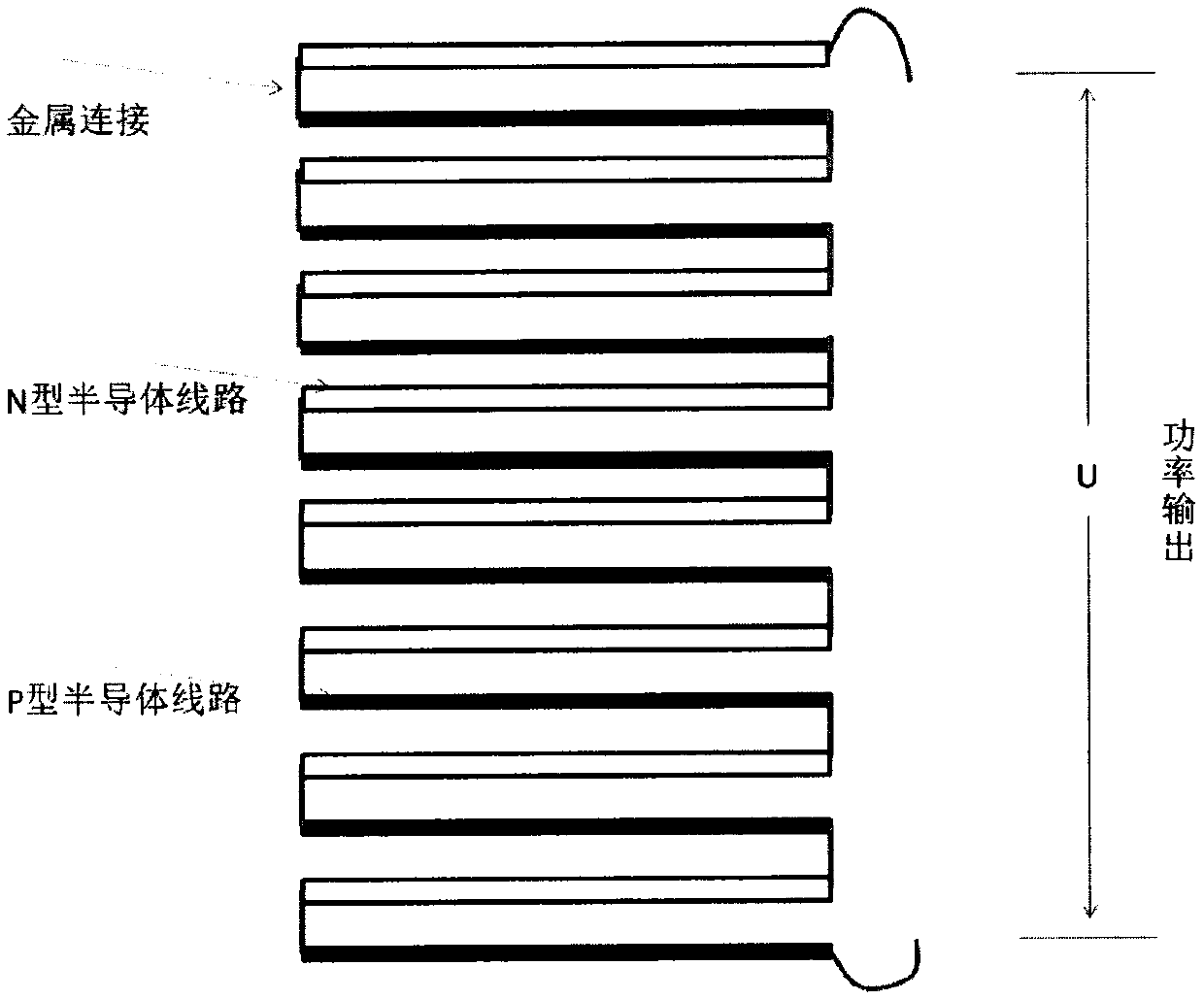

[0016] Sodium-doped tungsten oxide absorbing infrared blocking nano-coating is coated on the sunlight incident side of ordinary silicate window glass, and indium tin oxide reflective infrared blocking nano-coating is coated on the sunlight outgoing side, and the side edge of the glass is a power generation circuit layer. Such as figure 1 shown. Vacuum Evaporation of P-type Bi Alternately Masked along the Glass Side and Normal to the Layer Plane of the Power Generation Circuit 2 Te 2.7 Se 0.3 Thermoelectric material circuit and N-type Bi 0.5 Sb 1.5 Te 3 Thermoelectric material lines, connected by silver lines to form N-P-N-P... Alternate series line structure, such as figure 2 shown. When sunlight is incident, the glass is transparent to visible light. The incident side of the glass absorbs infrared rays and heats up, while the outgoing side of the glass reflects infrared rays. A temperature difference occurs on both sides of the glass, and a potential difference is gen...

Embodiment 2

[0018] The sunlight incident side of the quartz window glass is coated with blue tungsten oxide absorbing infrared blocking nano-coating, and the sunlight exiting side is coated with tin oxide antimony reflective infrared blocking nano-coating. The side edge of the glass is the power generation circuit layer, the structure is as follows figure 1 shown. Alternate mask magnetron sputtering P-type PbSe thermoelectric material lines and N-type PbTe thermoelectric material lines along the normal direction of the power generation line layer plane on the side of the glass, and connect them through copper lines to form an alternating series circuit structure of N-P-N-P..., such as figure 2 shown. When sunlight is incident, the glass is transparent to visible light. The incident side of the glass absorbs infrared rays and heats up, while the outgoing side of the glass reflects infrared rays. A temperature difference occurs on both sides of the glass, and a potential difference is gene...

Embodiment 3

[0020] The solar incident side of the tempered window glass is coated with cesium-doped tungsten oxide absorbing infrared blocking nano-coating, and the sunlight-emitting side is coated with zinc oxide-aluminum reflective infrared blocking nano-coating. The side edge of the glass is a power generation circuit layer. The structure is as follows: figure 1 shown. Alternative inkjet printing of P-type graphene-filled polyphenylpyrrole thermoelectric material lines and N-type poly-3,4-ethylenedioxythiophene: polydiallyldimethylammonium chloride thermoelectric materials along the glass side edge and normal direction of the layer plane of the power generation circuit Material lines, connected by silver lines to form an alternating series line structure of N-P-N-P..., such as figure 2 shown. When sunlight is incident, the glass is transparent to visible light. The incident side of the glass absorbs infrared rays and heats up, while the outgoing side of the glass reflects infrared ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com