Ethylene-vinyl alcohol copolymer composition, and shaped product and application thereof

A technology of vinyl alcohol and copolymers, which is applied in the field of polymers and their molded products and applications, and can solve the problems of complex preparation methods, high cost, and no improvement in barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and

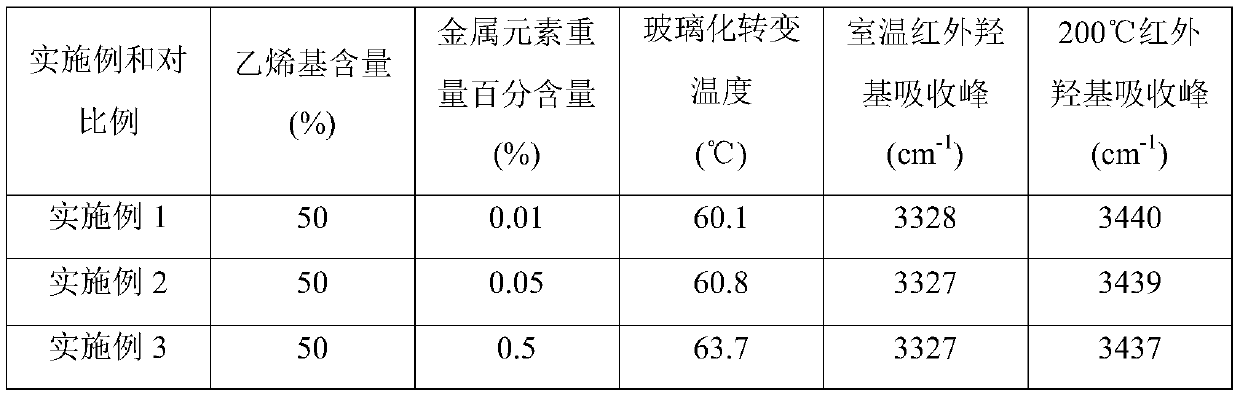

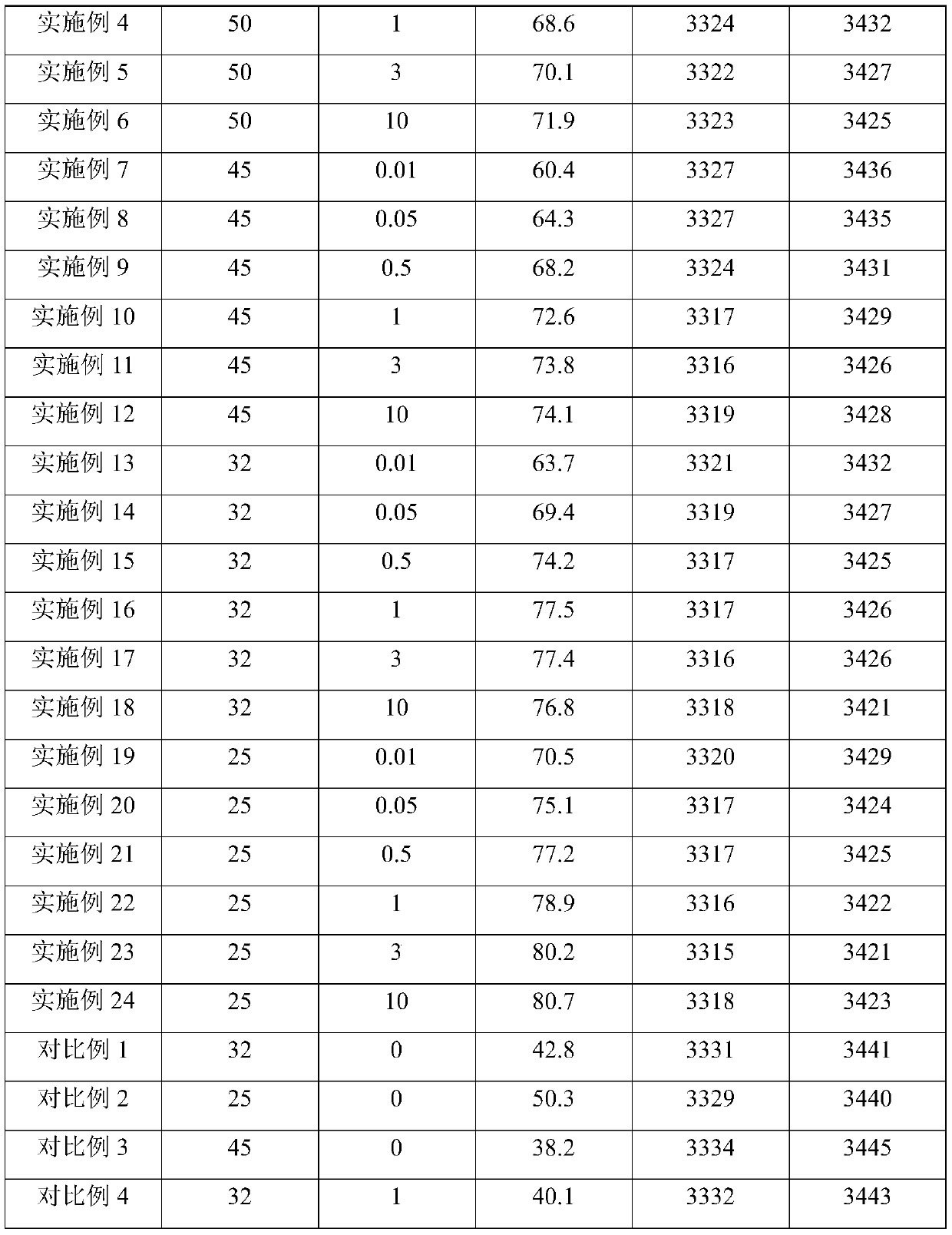

[0034] Embodiment and comparative example:

[0035] Examples 1-6: Under the pressure of 4-5MPa, methanol or tert-butanol is used as solvent, 25g of ethylene and 25g of vinyl acetate are added to the polymerization kettle, and then methanol is used as solvent and strong base is used as catalyst to copolymerize ethylene-vinyl acetate alcoholysis. Then add 0.005g, 0.025g, 0.25g, 0.5g, 1.5g, 5g of magnesium chloride to participate in the reaction, after the reaction is sufficient, wash with sodium acetate, and then dry to obtain ethylene-vinyl alcohol copolymer.

[0036] Examples 7-12: Under the pressure of 4-5MPa, methanol or tert-butanol is used as solvent, 22.5g ethylene and 27.5g vinyl acetate are added to the polymerization kettle, then methanol is used as solvent and strong base is used as catalyst, and ethylene-acetic acid The ethylene copolymer undergoes alcoholysis. Then add 0.005g, 0.025g, 0.25g, 0.5g, 1.5g, 5g of magnesium chloride to participate in the reaction, afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com