Novel titanium alloy surface electroplating method

A titanium alloy, a new type of technology, applied in the field of photoelectric deposition, can solve problems such as resistance increase and deposition, and achieve the effects of improving electrical conductivity, simple process, and increasing electric field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

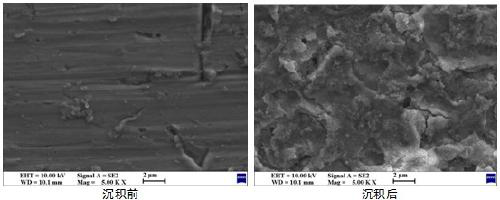

Image

Examples

Embodiment 1

[0028] A novel titanium alloy surface electroplating method, comprising the following steps:

[0029] 1) Ultrasonic clean the titanium alloy with acetone for 10 minutes, rinse it with deionized water and dry it for later use;

[0030] 2) Put the sample into the furnace for sintering, the sintering temperature is 300°C, and the holding time is 1h;

[0031] 3) Configure 0.1mol / L AgNO 3 solution, stirred for 10 min to obtain an electrolyte;

[0032] 4) Use titanium alloy as the cathode and platinum sheet as the anode, keep a constant distance, and irradiate with a light source, the wavelength of the light source is 430nm, and the optical power density is 20mW / cm 2 , and use the electrolyte in step 3), electroplating with a water bath at a constant temperature of 25°C, a current of 50mA, and a time of 0.5h;

[0033] 5) The sample obtained in step 4) is ultrasonically cleaned and then dried to obtain an electroplated titanium alloy.

Embodiment 2

[0035] A novel titanium alloy surface electroplating method, comprising the following steps:

[0036] 1) Ultrasonic clean the titanium alloy with acetone for 10 minutes, rinse it with deionized water and dry it for later use;

[0037] 2) Put the sample into the furnace for sintering, the sintering temperature is 300℃, and the holding time is 2h;

[0038] 3) Configure 0.2mol / L CuCl 2 solution, stirred for 1h to obtain an electrolyte;

[0039] 4) Use titanium alloy as the cathode and platinum sheet as the anode, keep a constant distance, and irradiate with a light source. The wavelength of the light source is 400nm, and the optical power density is 10mW / cm 2 , and use the electrolyte in step 3) to deposit copper at a water bath with a constant temperature of 25°C, with a deposition current of 30mA and a time of 2h;

[0040] 5) The sample obtained in step 4) is ultrasonically cleaned and then dried to obtain an electroplated titanium alloy.

Embodiment 3

[0042] A novel titanium alloy surface electroplating method, comprising the following steps:

[0043] 1) Ultrasonic clean the titanium alloy with acetone for 10 minutes, rinse it with deionized water and dry it for later use;

[0044] 2) Put the sample into the furnace for sintering, the sintering temperature is 450℃, and the holding time is 3h;

[0045] 3) Prepare 0.1mol / L KI solution and stir for 10 minutes to obtain the electrolyte;

[0046] 4) Use titanium alloy as the anode and platinum sheet as the cathode, keep a constant distance, and irradiate with a light source. The wavelength of the light source is 380nm, and the optical power density is 30mW / cm 2 , and use the electrolyte in step 3) to deposit iodine in a water bath at a constant temperature of 40°C, with a deposition current of 100mA and a time of 30min;

[0047] 5) The sample obtained in step 4) is ultrasonically cleaned and then dried to obtain an electroplated titanium alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com