Enzyme-containing alkaline membrane cleaning agent and application thereof

A cleaning agent and alkaline membrane technology, applied in the field of membrane cleaning, can solve the problems of good cleaning recovery effect, high cleaning concentration, damage, etc., and achieve the effects of low cleaning maintenance cost, high cleaning recovery rate, and good chemical safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

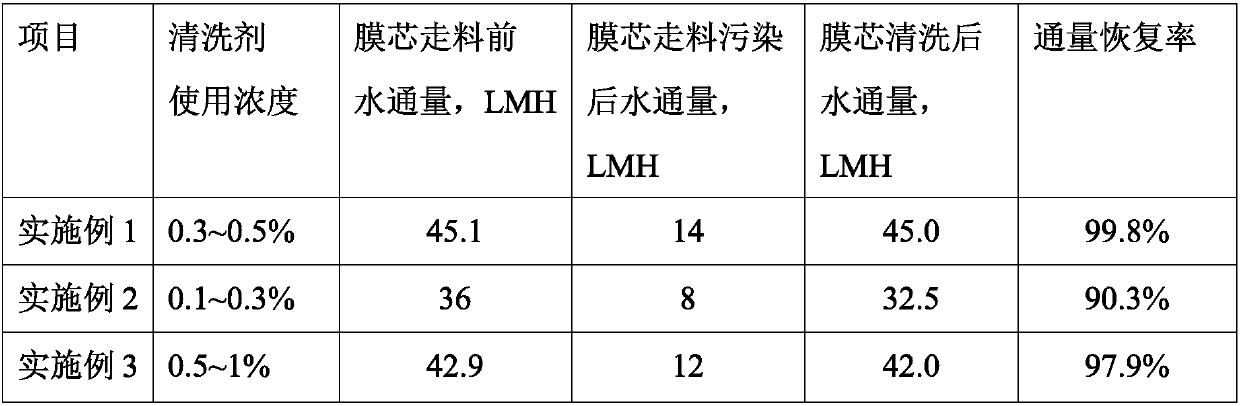

Embodiment 1

[0032] An enzyme-containing alkaline film cleaning agent, the mass percentage of its components is 30% sodium hydroxide, 30% AEO-7 surfactant, 10% sodium citrate, 20% sodium tripolyphosphate, 10% protease, and The preparation method is as follows:

[0033] (1) Take each component by weighing;

[0034] (2) Fully mix the components except the enzyme preparation;

[0035] (3) adding an enzyme preparation to the material obtained in step (2) while stirring, and then passing through a sieve to obtain the enzyme-containing alkaline membrane cleaning agent.

[0036] Prepare the above enzyme-containing alkaline membrane cleaning agent into an aqueous solution with a concentration of 0.3-0.5 wt%, and then clean the membrane module, as follows:

[0037] The polluted membrane core used in this example is the nanofiltration membrane core in the erythromycin fermentation broth, and its pollution characteristics: the flux drops by 70%. As a new separation technology, membrane treatment i...

Embodiment 2

[0044] An enzyme-containing alkaline film cleaning agent, the mass percentage of its components is 45% sodium hydroxide, 25% AEO-9 surfactant, 10% EDTA, 15% potassium pyrophosphate, and 5% protease. Its preparation method is as follows:

[0045] (1) Take each component by weighing;

[0046] (2) Fully mix the components except the enzyme preparation;

[0047] (3) adding an enzyme preparation to the material obtained in step (2) while stirring, and then passing through a sieve to obtain the enzyme-containing alkaline membrane cleaning agent.

[0048] Prepare the above enzyme-containing alkaline membrane cleaning agent into an aqueous solution with a concentration of 0.1 to 0.3 wt%, and then clean the membrane core, as follows:

[0049] The polluted membrane core used in this example is the nanofiltration membrane core in the gibberellin fermentation broth. Its pollution characteristics: the membrane flux drops rapidly, and the water flux continues to decline after operation. By...

Embodiment 3

[0056] A kind of enzyme-containing alkaline film cleaning agent, the mass percent of its components is sodium carbonate 45%, AEO-9 surfactant 25%, EDTA 10%, potassium pyrophosphate 15%, protease 5%, and its preparation method is as follows:

[0057] (1) take each component;

[0058] (2) Fully mix the components except the enzyme preparation;

[0059] (3) adding an enzyme preparation to the material obtained in step (2) while stirring, and then passing through a sieve to obtain the enzyme-containing alkaline membrane cleaning agent.

[0060] The above enzyme-containing alkaline membrane cleaning agent is formulated into an aqueous solution with a concentration of 0.5 to 1 wt%, and then the roll-type ultrafiltration membrane is cleaned, as follows:

[0061] The polluted membrane core used in this example is a roll-type ultrafiltration membrane core in the amino acid fermentation liquid. Its pollution characteristics: the membrane flux drops rapidly, and the water flux continues...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com