A system and method for multi-information acquisition and monitoring of robot welding process

A robot welding, collection and monitoring technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem of inability to realize remote multi-information wireless monitoring of the welding process, inability to realize online adjustment of welding parameters, real-time control of welding quality, and inability to obtain real-time information Problems such as molten pool dynamic information can be improved to improve manufacturing welding quality and production efficiency, improve welding product quality and reliability, and optimize production line management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

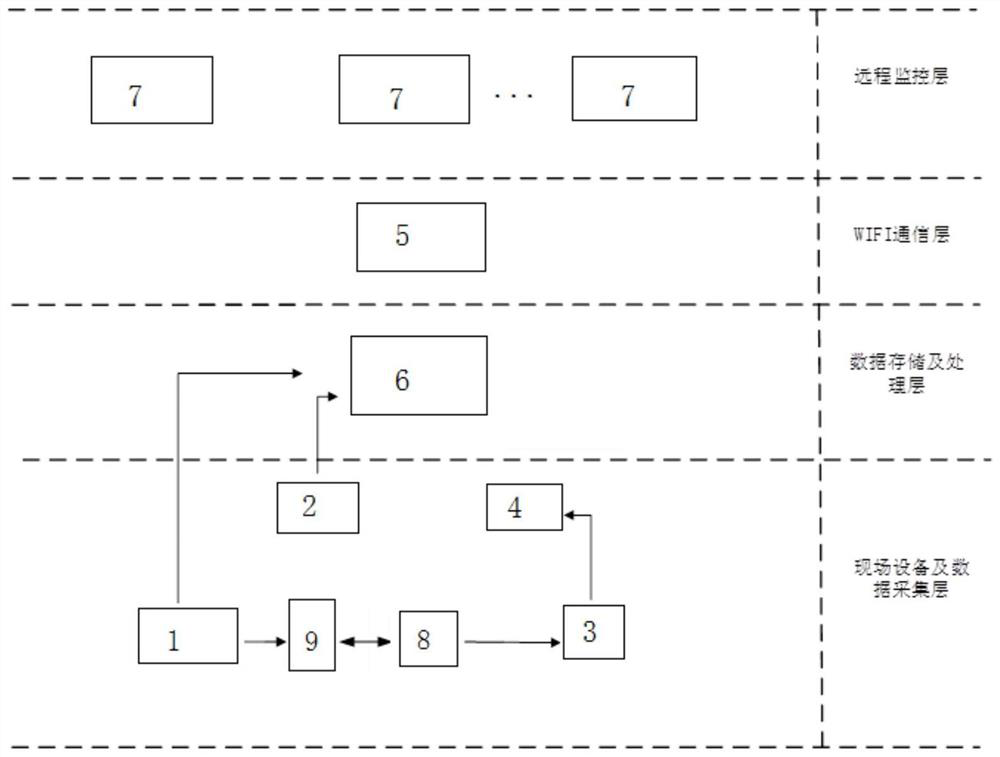

[0038] like figure 1 As shown, a multi-information acquisition and monitoring system for a robot welding process includes:

[0039] The robot control cabinet 1 is used to send walking and welding instructions to the robot 9, and send the real-time pose information of the robot welding torch and the welding arc start signal to the main control computer 6;

[0040] The welding visual sensing unit 2 is used for real-time acquisition of molten pool images in the dynamic process of robot welding. The arc light is projected onto the CCD photosensitive chip of the visual sensing system through the dimming filter of the dimming filter system of the welding arc. The photosensitive chip is converted into an electrical signal through photoelectric conversion, and the electrical signal is converted into an image signal through signal processing. The image of the molten pool collected by the system is clear, and the edge of the molten pool is relatively easy to extract;

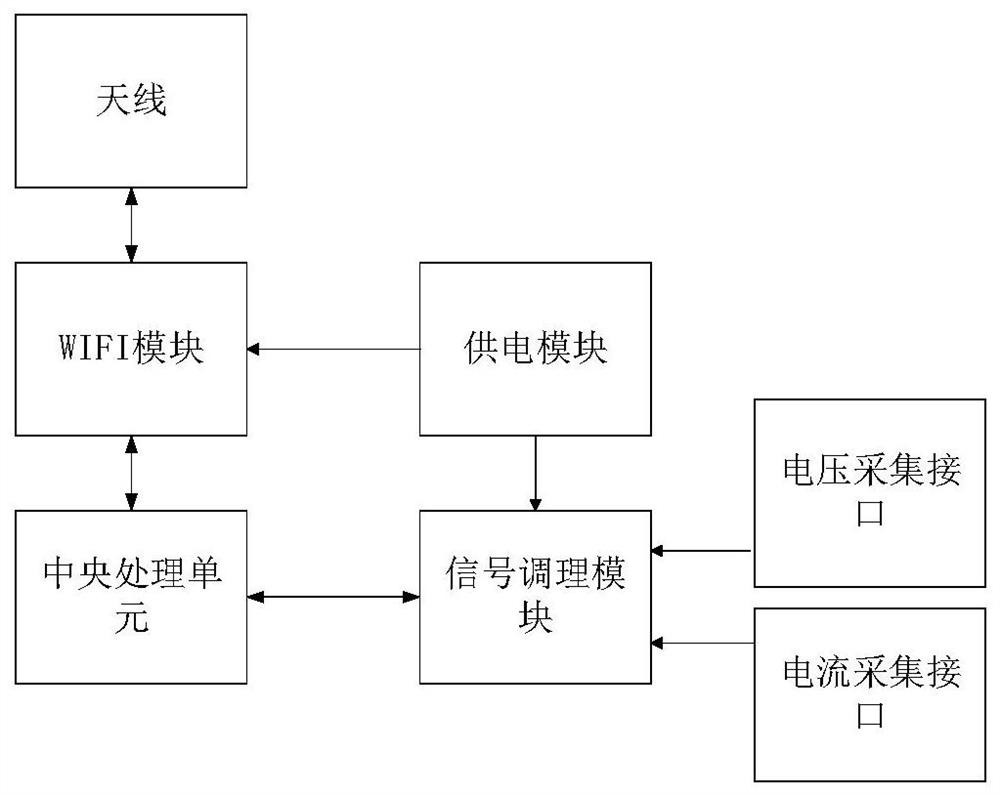

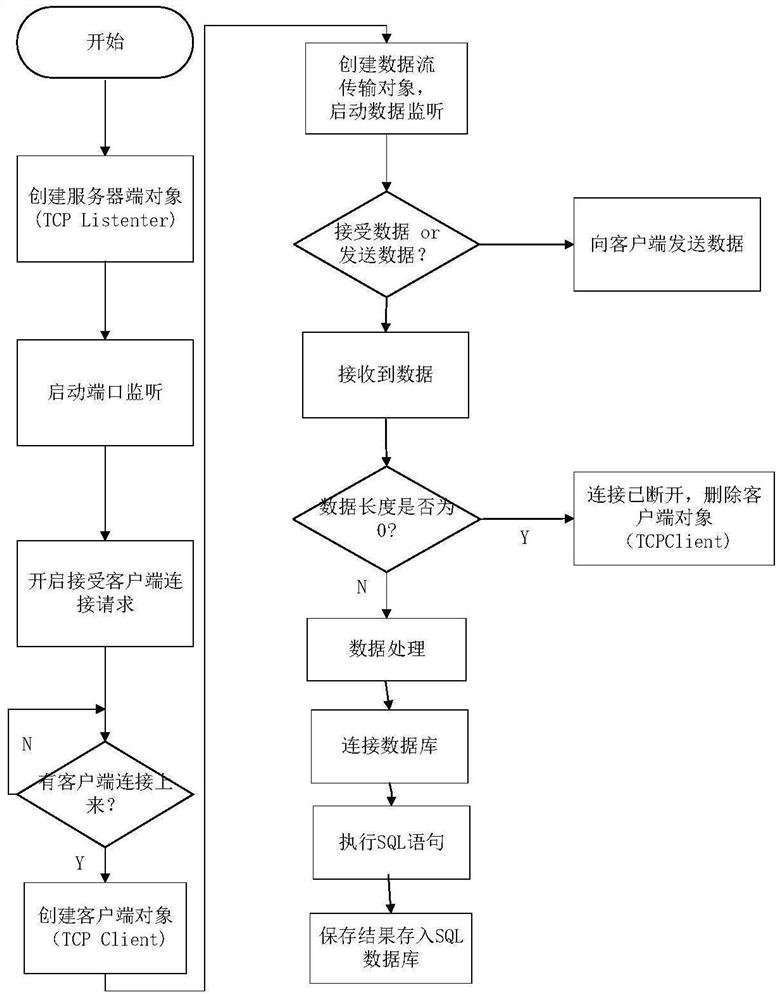

[0041] The weldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com