A kind of aluminum hydroxide and preparation method thereof

A technology of aluminum hydroxide and aluminum compound is applied in the field of aluminum hydroxide of residue hydrotreating catalyst carrier and its preparation field, which can solve the problems of uneven particle size distribution, low efficiency, low product purity and crystallinity, etc. The particle size distribution is uniform, the process is simple, and the effect of promoting the nucleation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

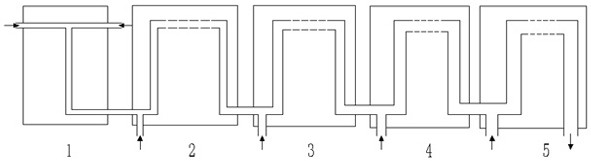

Image

Examples

Embodiment 1

[0039] Al 2 o 3 Calculated as 30g / 100mL of NaAlO 2 Solution and concentration in Al 2 o 3 Calculated as 50g / 100mL of Al 2 (SO 4 ) 3 Add the solution into the respective component tanks, put each raw material tank and the first impingement flow microreactor into the oil bath and heat to 90°C, turn on the booster pumps of the two component tanks, and simultaneously put the NaAlO 2 solution and Al 2 (SO 4 ) 3 The solution enters the first impingement flow reactor through the atomizer, and the NaAlO 2 The flow rate of the solution is 15mL / min, adjust the pH value in the impingement flow reactor to 8.5, and carry out the neutralization and precipitation reaction, and the reaction mixture enters the second microreactor after staying in the first impingement flow microreactor for 1min; Microwave heating raises the reaction temperature of the second microreactor to 110 ° C, turns on the booster pump of the second microreactor, and Al 2 (SO 4 ) 3 The solution is injected i...

Embodiment 2

[0041] Al 2 o 3 Calculated as 50g / 100mL of NaAlO 2 Solution and concentration in Al 2 o 3 Calculated as 50g / 100mL of Al 2 (SO 4 ) 3 Add the solution into the respective component tanks, put each raw material tank and the first impingement flow microreactor into an oil bath and heat to 80°C, turn on the booster pumps of the two component tanks, and simultaneously put the NaAlO 2 solution and Al 2 (SO 4 ) 3 The solution enters the first impingement flow reactor through the atomizer, and the NaAlO 2 The flow rate of the solution is 15mL / min, the pH value in the impingement flow reactor is adjusted to 9.0, and the neutralization and precipitation reaction is carried out. The reaction mixture enters the second microreactor after staying in the first impingement flow microreactor for 1.5min; Adopt microwave heating to raise the reaction temperature of the second microreactor to 100 ℃, turn on the booster pump of the second microreactor, and Al 2 (SO 4 ) 3 Solution is in...

Embodiment 3

[0043] Al 2 o 3 Calculated as 35g / 100mL of NaAlO 2 Solution and concentration in Al 2 o 3 Calculated as 50g / 100mL of Al 2 (SO 4 ) 3 Add the solution into the respective component tanks, put each raw material tank and the first impingement flow microreactor into the oil bath and heat to 120°C, turn on the booster pumps of the two component tanks, and simultaneously put the NaAlO 2 solution and Al 2 (SO 4 ) 3 The solution enters the first impingement flow reactor through the atomizer, and the NaAlO 2 The flow velocity of the solution is 15mL / min, adjust the pH value 8.5 in the impingement flow reactor, and carry out the neutralization precipitation reaction, and the reaction mixture enters the second microreactor after staying in the first impingement flow microreactor for 2min; Microwave heating raises the reaction temperature of the second microreactor to 140 ° C, turns on the booster pump of the second microreactor, and Al 2 (SO 4 ) 3 The solution is injected int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com