High-performance quenching oil

A quenching oil, high-performance technology, applied in the field of quenching cooling medium, can solve the problems of poor cooling performance and low flash point of quenching oil, achieve improved lubricity and dispersion, not easy to gel, reduce deformation and cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

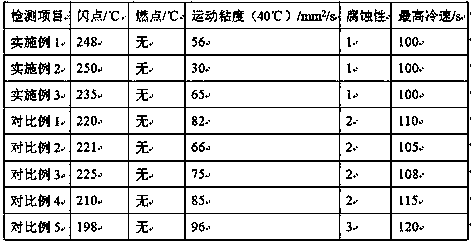

Examples

preparation example Construction

[0025]The preparation method of the cooling adjustment additive is: take polyethylene glycol-400 and add polypropylene glycol at a mass ratio of 3~6:2~5, heat up to 90~110°C and stir and mix for 60~90min to obtain the mixture, take 2-chloroethyl Vinyl ether is added dropwise to the mixture at a mass ratio of 3~5:5~10, stirred and mixed at 110~120°C for 3~5h, adjusted to pH 6.8~7, stirred and mixed for 20~30min, cooled to room temperature, and cooled Adjust additives.

[0026] The preparation method of flash point adjusting active agent is:

[0027] (1) Take bromooctane and add tetrahydrofuran according to the mass ratio of 2~5:5~10, pass through nitrogen protection, add magnesium bars with 5~10% bromooctane mass, stir and mix at 20~25°C for 20~30min, and get Stir the mixture, add diphenyldichlorosilane to the stirred mixture at a mass ratio of 3~6:20~40, stir and mix at 20~25°C for 1~3h, then raise the temperature to 50~60°C and keep it warm for 2~5h to obtain the stirred mix...

Embodiment 1

[0035] The alkenyl active agent is: take 1-butene and add α-olefin in a mass ratio of 3:2 to mix.

[0036] The benzene activator is: take dodecylbenzene and mix it with xylene at a mass ratio of 5~10:2~5.

[0037] The raw material of oil-based quenching oil is: take the alkenyl active agent and add the benzene active agent in a mass ratio of 3:1, heat up to 40°C and stir and mix for 30 minutes, then add bis(tetramethylcyclopentadiene base) zirconium dichloride, heated up to 60°C and stirred and mixed for 1 hour to obtain a mixed solution. Take the mixed solution and add distilled water at a mass ratio of 10:2, let it stand for 30 minutes, take the supernatant and distill it under reduced pressure to obtain the oil-based quenching oil raw material.

[0038] The preparation method of the cooling adjustment additive is: take polyethylene glycol-400 and add polypropylene glycol at a mass ratio of 3:2, heat up to 90°C and stir and mix for 60 minutes to obtain a mixture, and take 2-...

Embodiment 2

[0048] The alkenyl active agent is: take 1-butene and add α-olefin in a mass ratio of 7:5 to mix.

[0049] The benzene activator is: take dodecylbenzene and mix it with xylene at a mass ratio of 5~10:2~5.

[0050] The raw material of oil-based quenching oil is: take alkenyl activator and add benzene activator at a mass ratio of 5:3, heat up to 50°C and stir and mix for 50 minutes, then add bis(tetramethylcyclopentadiene) with 5% mass of alkenyl activator Base) zirconium dichloride, heat up to 70°C and stir and mix for 4 hours to obtain a mixed solution. Take the mixed solution and add distilled water at a mass ratio of 20:7, let it stand for 50 minutes, take the upper liquid and distill it under reduced pressure to obtain the oil-based quenching oil raw material.

[0051] The preparation method of the cooling adjustment additive is: take polyethylene glycol-400 and add polypropylene glycol at a mass ratio of 6:5, heat up to 110°C and stir and mix for 90 minutes to obtain a mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com