Preparing method of oxygen-generation nano-liposome

A nano-liposome and product technology, which is applied in liposome delivery, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of poor safety performance and low stability, and achieve High performance stability, high repeatability, easy to promote the effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

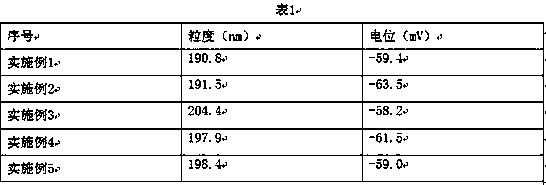

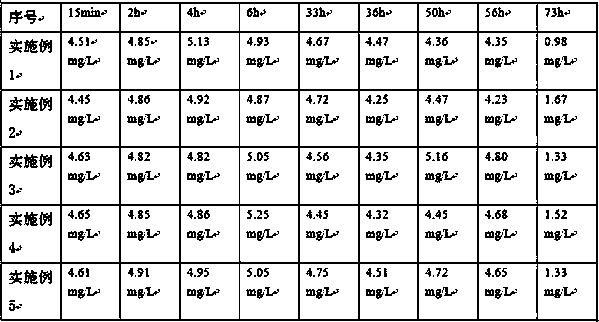

Examples

Embodiment 1

[0029] A preparation method of oxygen-producing nanoliposomes, comprising the following steps:

[0030] (1) Add soybean lecithin to cyclohexane, vortex, and mix under ultrasonic wave for 4 minutes to obtain a mixed solution. The amount of soybean lecithin added to cyclohexane is 10 mg per milliliter;

[0031] (2) Add 20 mg / ml pectin solution to the mixture, stir for 35 minutes, and mix under ultrasonic waves for 18 minutes to obtain a suspension. The volume ratio of the pectin solution to cyclohexane in step (1) is 0.8 :100;

[0032] (3) Add 10 mg / ml sodium percarbonate solution to the suspension, vortex, and ultrasonically mix at 10°C for 18 minutes to obtain a mixed stirring liquid, the sodium percarbonate solution and cyclohexane in step (1) The volume ratio of alkane is 0.8:100;

[0033] (4) Add 1.4mg / ml calcium hydroxide solution to the mixing solution, stir at 10°C for 8 minutes, and ultrasonically mix at 10°C for 18 minutes to obtain a calcium hydroxide solution mixtu...

Embodiment 2

[0039] A preparation method of oxygen-producing nanoliposomes, comprising the following steps:

[0040] (1) Add soybean lecithin to chloroform, vortex, and mix under ultrasonic waves for 6 minutes to obtain a mixed solution. The amount of soybean lecithin added per milliliter of chloroform is 15 mg;

[0041] (2) Add 30 mg / ml pectin solution to the mixture, stir for 45 minutes, and mix under ultrasonic waves for 25 minutes to obtain a suspension. The volume ratio of the pectin solution to the chloroform in step (1) is 1.2: 100;

[0042] (3) Add 20 mg / ml sodium percarbonate solution to the suspension, vortex, and ultrasonically mix at 15°C for 25 minutes to obtain a mixed stirring liquid, the mixture of the sodium percarbonate solution and the chloroform in step (1) The volume ratio is 1.2:100;

[0043](4) Add 1.8mg / ml calcium hydroxide solution to the mixing solution, stir at 15°C for 12 minutes, and ultrasonically mix at 15°C for 25 minutes to obtain a calcium hydroxide solu...

Embodiment 3

[0049] A preparation method of oxygen-producing nanoliposomes, comprising the following steps:

[0050] (1) Add soybean lecithin to the mixed solvent of chloroform and cyclohexane, vortex, and mix under ultrasonic waves for 5 minutes to obtain a mixed solution. The amount of soybean lecithin added per milliliter of mixed solvent of chloroform and cyclohexane is 25mg, the volume ratio of chloroform and cyclohexane in the mixed solvent of chloroform and cyclohexane is chloroform: cyclohexane=1:1;

[0051] (2) Add 25 mg / ml pectin solution to the mixture, stir for 40 minutes, and mix under ultrasonic waves for 20 minutes to obtain a suspension. The mixture of the pectin solution and chloroform and cyclohexane in step (1) The volume ratio of the solvent is 1:100;

[0052] (3) Add 15 mg / ml sodium percarbonate solution to the suspension, vortex, and ultrasonically mix at 12°C for 20 minutes to obtain a mixed stirring liquid, the sodium percarbonate solution and the chloroform in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com