Magnetically-separable activated carbon composite material preparation method

A technology of composite materials and magnetic activated carbon, applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of reduced decontamination efficiency, filter blockage and damage, secondary pollution, etc., and achieves simple operation and realization of reuse Utilization, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

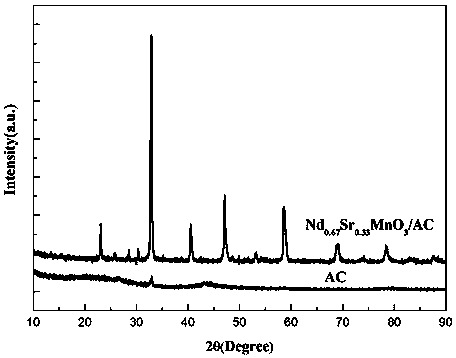

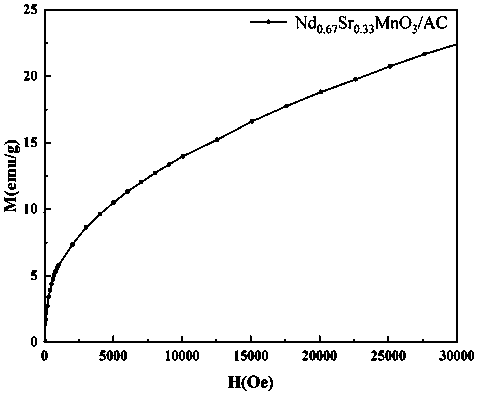

[0009] Specific implementation method 1: Firstly, the activated carbon is pulverized into activated carbon particles, which are screened through a 200-mesh sieve; the surface of the activated carbon particles is modified with concentrated sulfuric acid, fully washed (pH=7) and dried. Take 5 parts of activated carbon, 2 parts of Nd(NO 3 ) 3 ·6H 2 O, 1 part of Sr(NO 3 ) 2 and 3 parts of Mn(NO 3 ) 2 Dissolve in a mixed solution of 40 parts of deionized water and 20 parts of alcohol, and stir magnetically at 80°C for 1 hour. Then add 6 parts of citric acid and a few drops of ethylene glycol as a complexing agent, stir for 2 hours, add ammonia water dropwise to adjust the pH of the solution to 7, adjust the temperature of the water bath to 80°C, and stir until the solution becomes a sol state. The obtained sol was transferred to a blast drying oven for drying at 80° C. for 6 hours to obtain a gel. Under nitrogen protection, the gel was sintered in a tube furnace at 800 °C fo...

specific Embodiment approach 2

[0010] Specific embodiment 2: Firstly, the activated carbon is pulverized into activated carbon particles, which are screened through a 200-mesh sieve; the surface of the activated carbon particles is modified with concentrated sulfuric acid, fully washed (pH=7) and dried. Take 5 parts of activated carbon, 2 parts of La(NO 3 ) 3 ·6H 2 O, 1 part of Sr(NO 3 ) 2 and 3 parts of Mn(NO 3 ) 2 Dissolve in a mixed solution of 40 parts of deionized water and 20 parts of alcohol, and stir magnetically at 80°C for 1 hour. Then add 6 parts of citric acid and a few drops of ethylene glycol as a complexing agent, stir for 2 hours, add ammonia water dropwise to adjust the pH of the solution to 7, adjust the temperature of the water bath to 80°C, and stir until the solution becomes a sol state. The obtained sol was transferred to a blast drying oven for drying at 80° C. for 6 hours to obtain a gel. Under nitrogen protection, the gel was sintered in a tube furnace at 800 °C for 3 h. Aft...

specific Embodiment approach 3

[0011] Specific embodiment 3: The difference between this embodiment and specific embodiments 1 and 2 is that the amount of activated carbon in step 1 can be 3 to 10 parts. Others are the same as the first and second embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com