Healthy and environment-friendly paint and manufacturing process thereof

An environmentally friendly coating and manufacturing process technology, applied in the direction of antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of skin and mucous membrane irritation, unfavorable health, single function, etc., to improve mood, Maintain normal energy activity and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

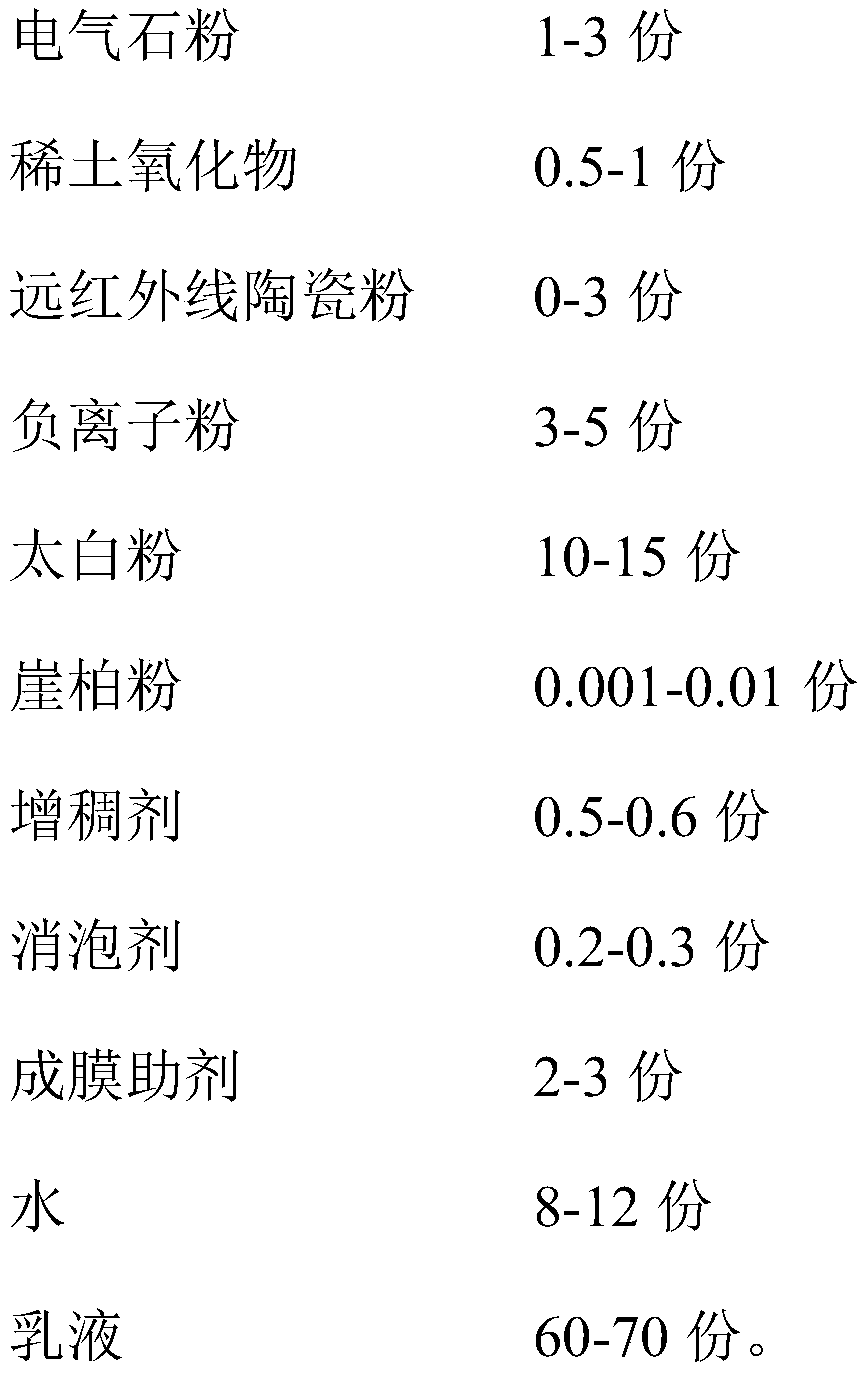

[0028] The healthy and environment-friendly paint of the present embodiment comprises the following components in parts by weight:

[0029]

[0030]

[0031] Further preferably, the particle size of the tourmaline powder, rare earth oxide, far-infrared ceramic powder, anion powder, cornstarch powder, and thuja powder is 3-5 μm. The particle size of the tourmaline powder, rare earth oxide, far-infrared ceramic powder, negative ion powder, cornstarch powder, and thuja powder is 3-5 μm, so that the particle size of the prepared healthy and environmentally friendly paint is small and fine.

[0032] The tourmaline powder is a borosilicate crystal and contains more than 10 trace elements beneficial to the human body, such as aluminum, iron, magnesium, sodium, lithium, potassium and other elements. Because it is a polar crystal with a special structure, it has high negative ion production and far-infrared emissivity. The normal energy activity of the human body can improve the...

Embodiment 2

[0046] The healthy and environment-friendly paint of the present embodiment comprises the following components in parts by weight:

[0047]

[0048] The tourmaline powder, rare earth oxide, far-infrared ceramic powder, negative ion powder, cornstarch powder, thuja powder, thickener, and film-forming aid of the present embodiment are the same as those in Embodiment 1, so they will not be repeated here. .

[0049] The defoamer in this embodiment is a mixture of polyoxyethylene polyoxypropanolamine ether, polyoxypropylene glyceryl ether, polyoxypropylene polyoxyethylene glyceryl ether and polydimethylsiloxane.

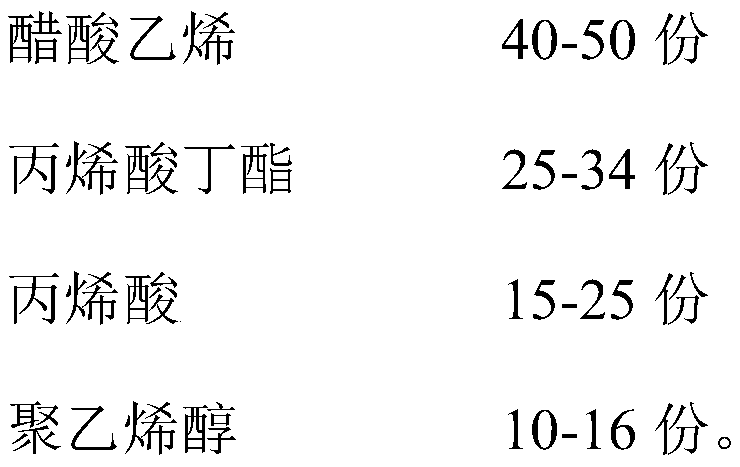

[0050] In parts by weight, the emulsion of the present embodiment includes:

[0051]

Embodiment 3

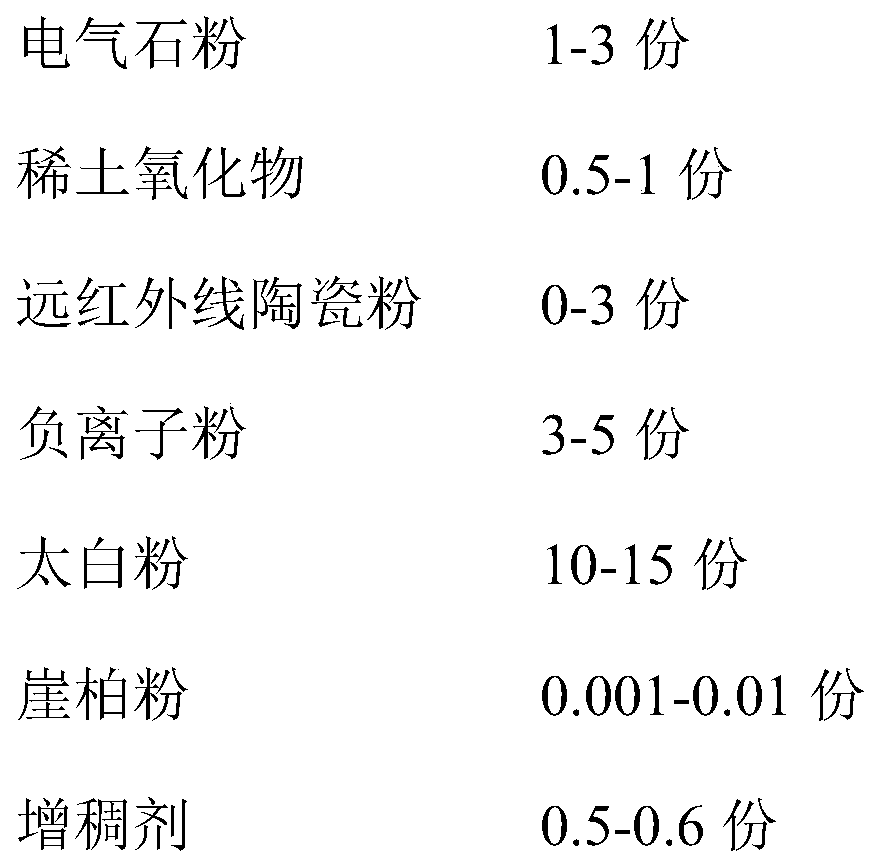

[0053] The healthy and environment-friendly paint of the present embodiment comprises the following components in parts by weight:

[0054]

[0055] The tourmaline powder, rare earth oxide, far-infrared ceramic powder, negative ion powder, cornstarch powder, thuja powder, thickener, and film-forming aid of the present embodiment are the same as those in Embodiment 1, so they will not be repeated here. .

[0056] The defoamer in this embodiment is a mixture of polyoxyethylene polyoxypropylene pentaerythritol ether and polyoxyethylene polyoxypropanolamine ether.

[0057] In parts by weight, the emulsion of the present embodiment includes:

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com