A kind of preparation method of magnesium alloy magnesium manganese hydrotalcite/micro-arc oxidation corrosion-resistant coating

An alloy magnesium manganese water, micro-arc oxidation technology, applied in metal material coating process, coating, anodizing and other directions, can solve the problems of increasing cost and technological process, complex preparation process, accelerated alloy corrosion, etc., to reduce corrosion Current density, broad application prospects, effect of delaying corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

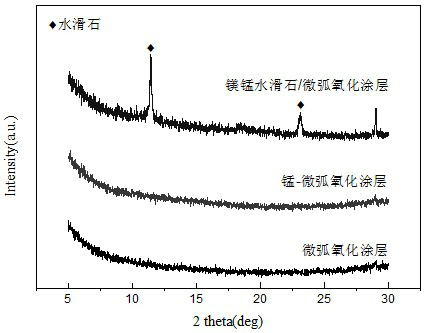

[0027] Embodiment 1 The preparation method of magnesium manganese hydrotalcite / micro-arc oxidation coating

[0028] (1) Pretreatment: Grinding the surface of the magnesium alloy sample smooth, then washing and drying;

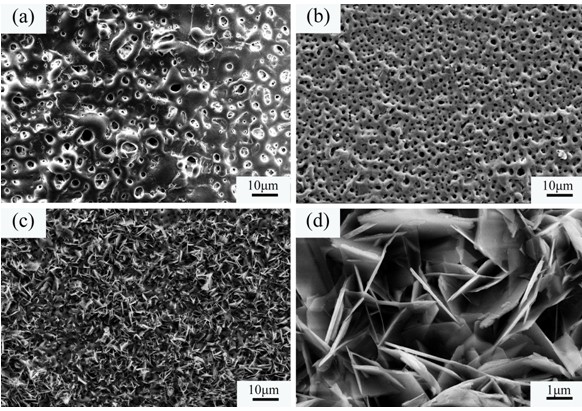

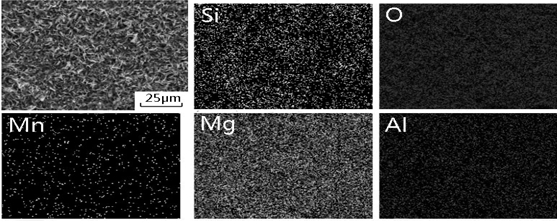

[0029] (2) Magnesium alloy micro-arc oxidation: the dried magnesium alloy sample was subjected to micro-arc oxidation in constant current mode, the treatment time was 20 minutes, and the frequency was 800 Hz to obtain a manganese-micro-arc oxidation sample; the electrolyte composition of micro-arc oxidation was as follows : Sodium silicate 20g / L, potassium hydroxide 30g / L, potassium fluoride 10g / L, potassium permanganate 2g / L.

[0030] (3) Hydrothermal reaction: The manganese-micro-arc oxidation sample obtained in step (2) was placed in deionized water for hydrothermal reaction. The reaction temperature was 120°C and the reaction time was 15 hours. Arc oxidation coating.

Embodiment 2

[0032] (1) Pretreatment: Grinding the surface of the magnesium alloy sample smooth, then washing and drying;

[0033] (2) Magnesium alloy micro-arc oxidation: the dried magnesium alloy sample was subjected to micro-arc oxidation in constant current mode, the treatment time was 5 minutes, and the frequency was 600 Hz to obtain a manganese-micro-arc oxidation sample; the electrolyte composition of micro-arc oxidation was as follows : Sodium silicate 5g / L, potassium hydroxide 5g / L, potassium fluoride 1g / L, potassium permanganate 1g / L.

[0034] (3) Hydrothermal reaction: The manganese-micro-arc oxidation sample obtained in step (2) was placed in deionized water for hydrothermal reaction. Arc oxidation coating.

Embodiment 3

[0036] (1) Pretreatment: Grinding the surface of the magnesium alloy sample smooth, then washing and drying;

[0037] (2) Magnesium alloy micro-arc oxidation: The dried magnesium alloy sample was subjected to micro-arc oxidation in constant current mode, the treatment time was 10 minutes, and the frequency was 700 Hz to obtain a manganese-micro-arc oxidation sample; the electrolyte composition of micro-arc oxidation was as follows : Sodium silicate 10g / L, potassium hydroxide 10g / L, potassium fluoride 5g / L, potassium permanganate 2g / L.

[0038] (3) Hydrothermal reaction: The manganese-micro-arc oxidation sample obtained in step (2) was placed in deionized water for hydrothermal reaction. The reaction temperature was 120°C and the reaction time was 15 hours. Arc oxidation coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com