Partition board and preparation method thereof

A technology for partition board and titanium tailings extraction, applied in the field of building materials, can solve the problems of pollution, the land occupation of titanium tailings and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

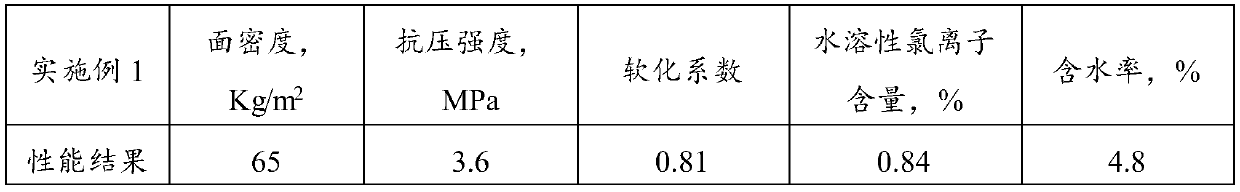

Embodiment 1

[0082] The mass ratio of raw materials for preparing lightweight partition wall panels in Example 1 of the present invention is: 25wt% of titanium tailings, 47wt% of lightly burned magnesium oxide, 24wt% of industrial magnesium sulfate, 3wt% of fly ash, and 0.4wt% of straw fiber , compound admixture 0.5wt%, foaming agent 0.1wt%; The composition of compound admixture is: 25wt% iron alum, 15wt% sugar calcium, 15wt% calcium chloride, 20wt% silica fume, 5wt% % water reducer, 20wt% sucrose. The preparation method of the compound admixture is as follows: mixing iron alum, sugar calcium, calcium chloride, silica fume, water reducing agent and sucrose according to the above-mentioned mass content ratio.

[0083] The preparation method comprises the following steps:

[0084] 1) Industrial magnesium sulfate was dissolved in water 20 hours in advance, configured into an aqueous magnesium sulfate solution with a Baume degree of 25 ° Be, and the precipitate was filtered to obtain a clear ...

Embodiment 2

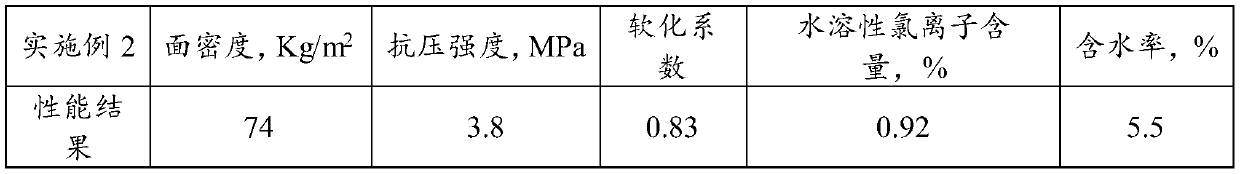

[0094] According to the method of Example 1, the light-weight partition board is prepared. The difference from Example 1 is that the mass ratio of the raw materials of the light-weight partition board is: 33wt% of titanium tailings, 41wt% of light-burned magnesium oxide, industrial Magnesium sulfate 20wt%, fly ash 4wt%, straw fiber 0.63wt%, compound admixture 1.3wt%, blowing agent 0.07wt%; The composition of compound admixture is: 15wt% iron alum, 20wt% sugar Calcium, 5wt% calcium chloride, 20wt% silica fume, 15wt% water reducer, 25wt% sucrose. The preparation method of the compound admixture is as follows: mixing iron alum, sugar calcium, calcium chloride, silica fume, water reducing agent and sucrose according to the above-mentioned mass content ratio.

[0095] According to the method of Example 1, the performance of the lightweight partition wall panel prepared in Example 2 of the present invention was tested, and the test results are shown in Table 2.

[0096] Table 2 Per...

Embodiment 3

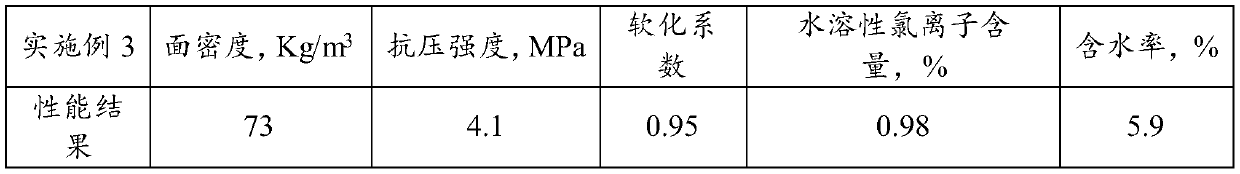

[0099] According to the method of Example 1, the light-weight partition board is prepared. The difference from Example 1 is that the mass ratio of the raw materials of the light-weight partition board is: 33wt% of titanium tailings, 41wt% of light-burned magnesium oxide, industrial Magnesium sulfate 20wt%, fly ash 3.5wt%, straw fiber 0.93wt%, compound admixture 1.5wt%, blowing agent 0.07wt%; Sugar calcium, 15wt% calcium chloride, 15wt% silica fume, 10wt% water reducer, 20wt% sucrose. The preparation method of the compound admixture is as follows: mixing iron alum, sugar calcium, calcium chloride, silica fume, water reducing agent and sucrose according to the above-mentioned mass content ratio.

[0100] According to the method of Example 1, the performance of the lightweight partition wall panel prepared in Example 3 of the present invention was tested, and the test results are shown in Table 3.

[0101] Table 3 The performance of the lightweight partition wall board prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com