Full-dull network stretch yarn and preparation method thereof

A full extinction and network technology, applied in the field of modified polyester fibers, can solve the problems of long natural degradation time and limit the application of chemical degradation and recycling, and achieve the effect of increasing the natural degradation rate, increasing the free volume of voids, and strong nucleophilic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The preparation method of full-dull network elastic yarn, the steps are as follows:

[0060] (1) prepare modified polyester;

[0061] (1.1) Synthesis of 2,5,6,6-tetramethyl-2,5-heptanediol;

[0062] (a) Mix KOH powder, 3-methyl-3-hydroxybutyne, 3,3-dimethyl-2-butanone and isopropyl ether at a molar ratio of 1:1:1.2:2.0, and place in an ice bath Under the conditions of reaction for 2h, cooling crystallization, centrifugation, washing, refining and drying are carried out after the reaction to obtain octyne diol;

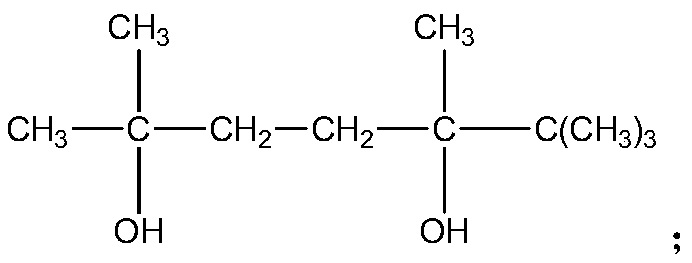

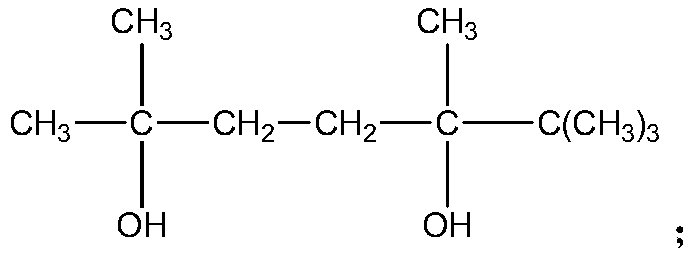

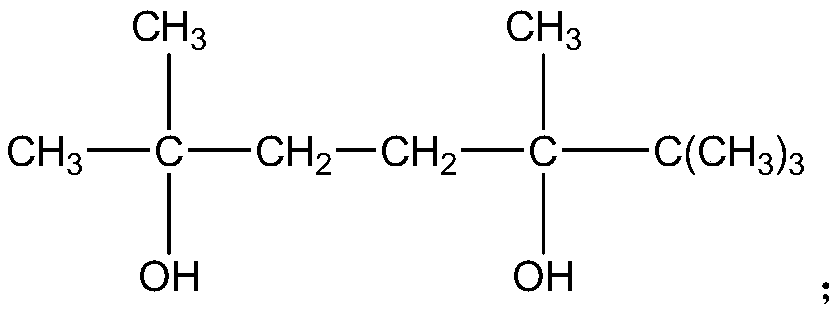

[0063] (b) Mix octynediol, ethanol and palladium catalyst in a weight ratio of 2:10:0.01, react at a temperature of 40°C for 50 minutes, continuously feed hydrogen during the reaction, and separate and purify after the reaction to obtain 2,5,6,6-tetramethyl-2,5-heptanediol, the structural formula of 2,5,6,6-tetramethyl-2,5-heptanediol is shown in formula (I);

[0064] (1.2) prepare MgO powder;

[0065] First heat MgO to 400°C and keep it warm for 2 hours, th...

Embodiment 2

[0082] The preparation method of full-dull network elastic yarn, the steps are as follows:

[0083] (1) prepare modified polyester;

[0084] (1.1) Preparation of 2,5,6,6-tetramethyl-2,5-heptanediol;

[0085] (a) Mix KOH powder, 3-methyl-3-hydroxybutyne, 3,3-dimethyl-2-butanone and isopropyl ether at a molar ratio of 1.1:1:1.2:2.3, and place in an ice bath Under the conditions of reaction for 2h, cooling crystallization, centrifugation, washing, refining and drying are carried out after the reaction to obtain octyne diol;

[0086] (b) Mix octynediol, ethanol and palladium catalyst in a weight ratio of 2:10:0.01, react at a temperature of 45°C for 50 minutes, continuously feed hydrogen during the reaction, and separate and purify after the reaction to obtain 2,5,6,6-tetramethyl-2,5-heptanediol, the structural formula of 2,5,6,6-tetramethyl-2,5-heptanediol is shown in formula (I);

[0087] (1.2) prepare BaO powder;

[0088] First heat BaO to 400°C and keep it warm for 3 hours...

Embodiment 3

[0100] The preparation method of full-dull network elastic yarn, the steps are as follows:

[0101] (1) prepare modified polyester;

[0102] (1.1) Preparation of 2,5,6,6-tetramethyl-2,5-heptanediol;

[0103] (a) Mix KOH powder, 3-methyl-3-hydroxybutyne, 3,3-dimethyl-2-butanone and isopropyl ether at a molar ratio of 1.2:1:1.25:2.0, and place in an ice bath Under the conditions of reaction for 3 hours, after the reaction is completed, cooling and crystallization, centrifugation, washing, refining and drying are carried out to obtain octyne diol;

[0104] (b) Mix octynediol, ethanol and palladium catalyst in a weight ratio of 3:10:0.03, react at 40°C for 50 minutes, continuously feed hydrogen during the reaction, and separate and purify after the reaction to obtain 2,5,6,6-tetramethyl-2,5-heptanediol, the structural formula of 2,5,6,6-tetramethyl-2,5-heptanediol is shown in formula (I);

[0105] (1.2) Preparation of SiO 2 - BaO powder;

[0106] First heat the SiO 2 -BaO is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com