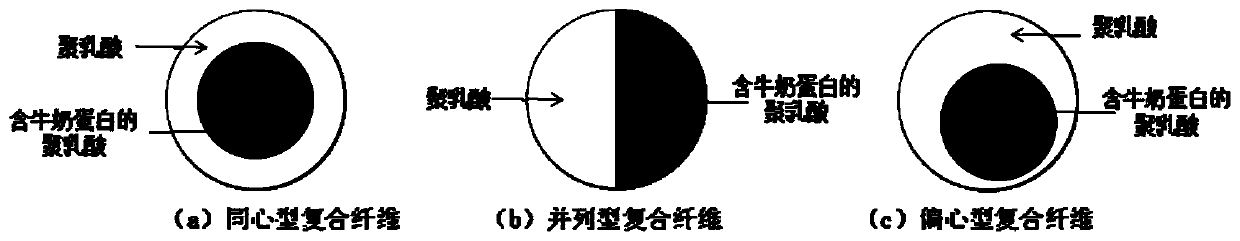

Modified polylactic acid biodegradable composite fiber containing milk protein

A technology of milk protein and composite fiber, which is applied in fiber treatment, fiber chemical characteristics, conjugated synthetic polymer artificial filament, etc., can solve the problems of poor dyeability and poor hygroscopicity of polylactic acid fiber, and achieve excellent performance, good moisture absorption and breathability properties, good hygroscopicity and dyeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

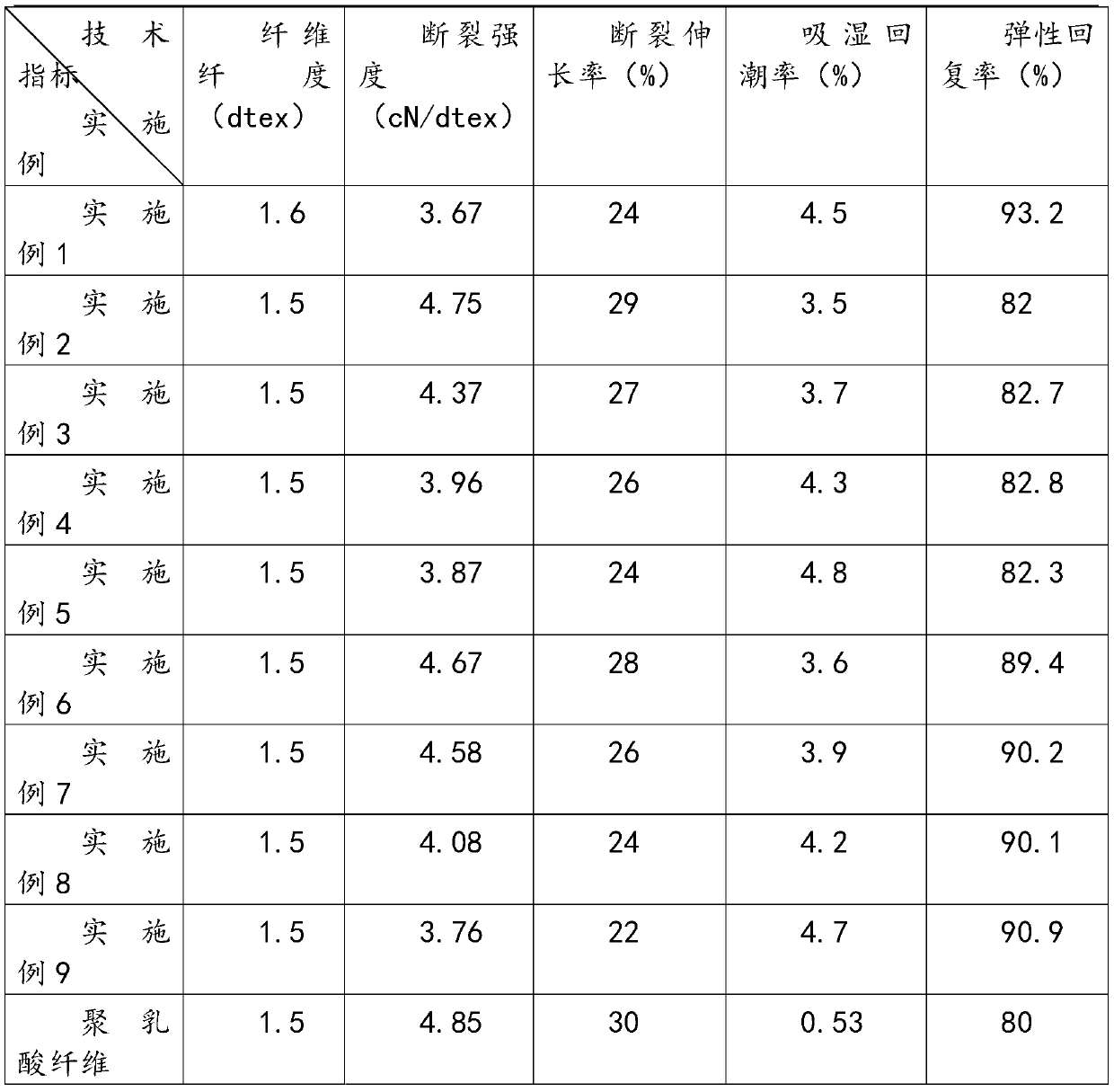

Examples

Embodiment 1

[0031] A method for preparing biodegradable composite fibers containing milk protein-modified polylactic acid, comprising the following steps:

[0032] a. Preparation of modified polylactic acid containing milk protein: 1. Measure 1000 parts by weight of fresh pure milk with a graduated cylinder, place it in an evaporator and evaporate it under reduced pressure for 12 hours, then take it out and place it in a conical flask, and place the conical flask Place in a centrifuge, the centrifuge speed is set to 1000r / min, add 100 parts by weight of NaOH aqueous solution after centrifugation for 4 hours, the protein in the lye is separated, add 50 parts by weight of NaCl solution with a mass fraction of 3%, Precipitate the protein, collect the precipitated protein in the Erlenmeyer flask, and obtain the milk protein for later use; 2. Mix the milk protein, DL-lactide, polyethanol, and initiator in a weight ratio of 5:6:2:0.3 , performing melt-initiated grafting in an internal mixer to ...

Embodiment 2

[0037] A preparation method of degradable composite fibers, comprising the following steps:

[0038] a. Preparation of modified polylactic acid containing milk protein: 1. Measure 1000 parts by weight of fresh pure milk with a graduated cylinder, place it in an evaporator and evaporate it under reduced pressure for 12 hours, then take it out and place it in a conical flask, and place the conical flask Place in a centrifuge, the centrifuge speed is set to 1100r / min, add 110 parts by weight of NaOH aqueous solution after centrifugation for 4 hours, the protein in the lye is separated, add 50 parts by weight of NaCl solution with a mass fraction of 3%, Precipitate the protein, collect the precipitated protein in the Erlenmeyer flask, and obtain the milk protein for later use; 2. Mix the milk protein, DL-lactide, polyethanol, and initiator in a weight ratio of 6:7:3.3:0.4 , performing melt-initiated grafting in an internal mixer to obtain a modified polylactic acid with a large mo...

Embodiment 3

[0043] A method for preparing biodegradable composite fibers containing milk protein-modified polylactic acid, comprising the following steps:

[0044] a. Preparation of modified polylactic acid containing milk protein: 1. Measure 1000 parts by weight of fresh pure milk with a graduated cylinder, place it in an evaporator and evaporate it under reduced pressure for 12 hours, then take it out and place it in a conical flask, and place the conical flask Place in a centrifuge, the centrifuge speed is set to 1300r / min, add 118 parts by weight of NaOH aqueous solution after centrifugation for 4 hours, the protein in the lye is separated, add 50 parts by weight of NaCl solution with a mass fraction of 3%, Precipitate the protein, collect the precipitated protein in the Erlenmeyer flask, and obtain the milk protein for later use; 2. Mix the milk protein, DL-lactide, polyethanol, and initiator in a weight ratio of 8:8:6:0.6 , performing melt-initiated grafting in an internal mixer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com