Nickel selenide/nickel hydroxide composite material applied to supercapacitor and preparation method of nickel selenide/nickel hydroxide composite material

A technology of supercapacitors and composite materials, which is applied in the manufacture of hybrid/electric double-layer capacitors, electrodes of hybrid capacitors, etc., can solve problems such as limiting the large-scale application of composite materials, and achieve the benefits of electrochemical reactions, increase capacitor capacity, and high specific capacitance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

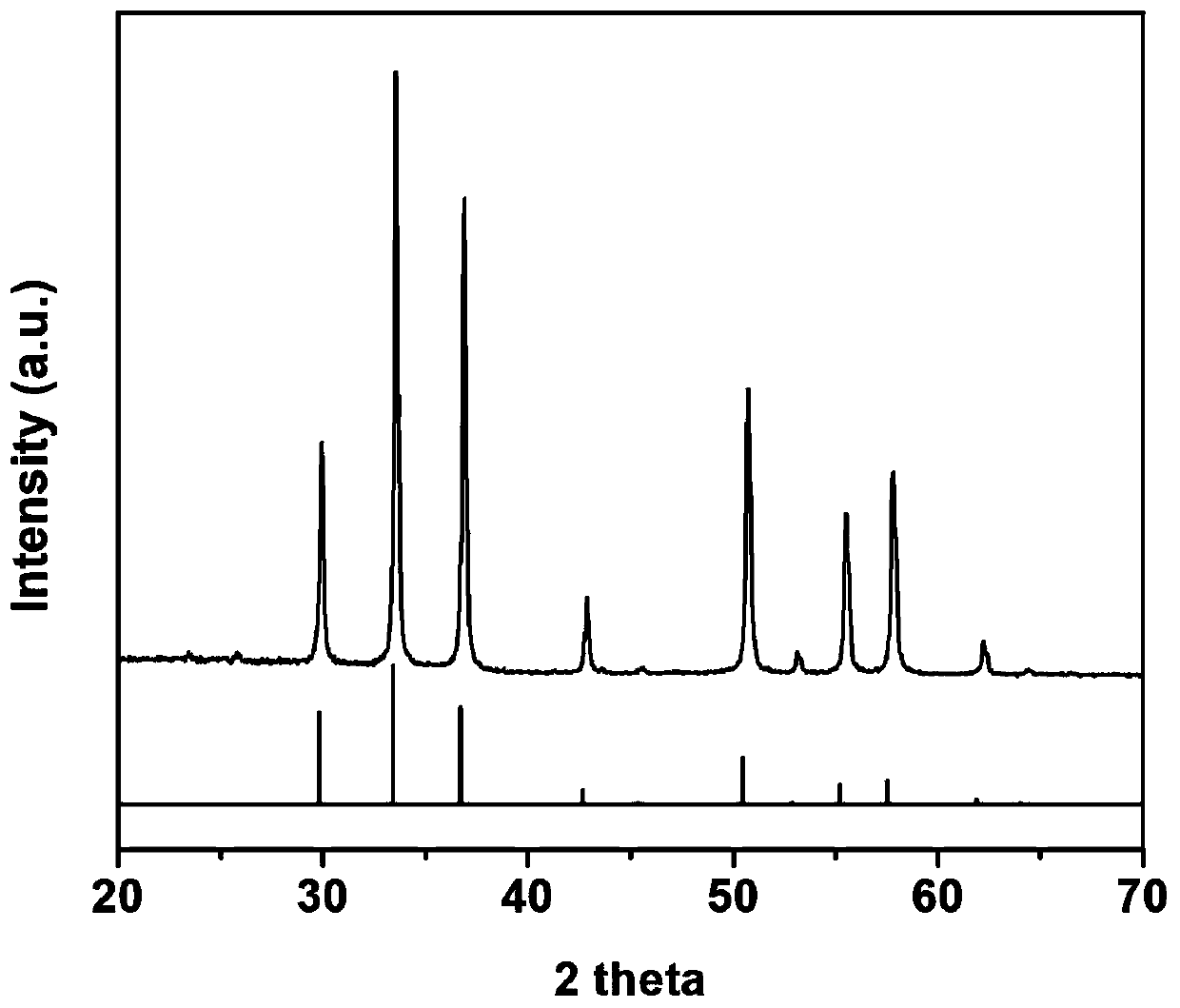

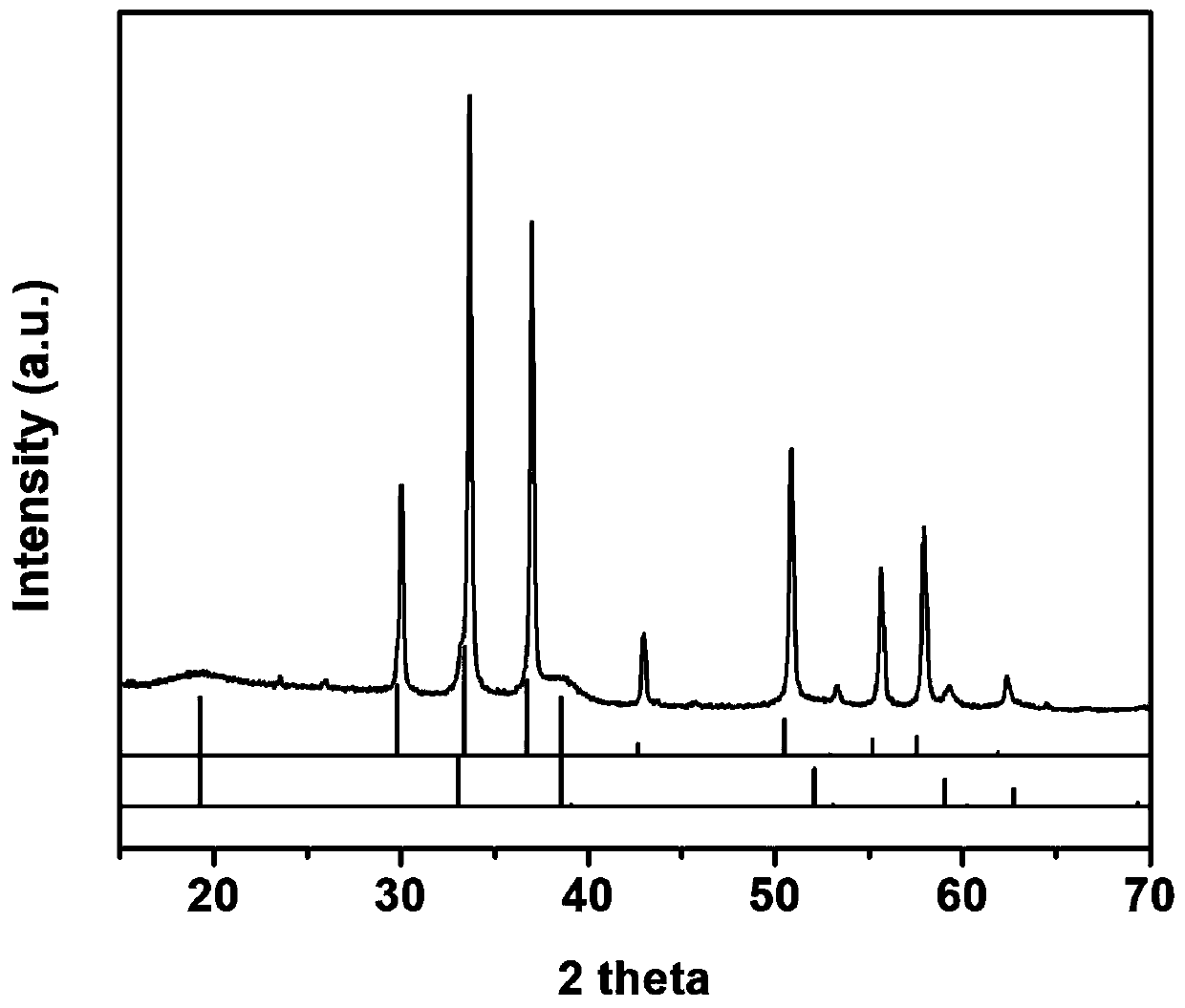

[0027] (1) Octahedral bulk NiSe 2 Preparation: Weigh 0.5mmol (0.1454g) nickel nitrate hexahydrate and dissolve it in 10ml deionized water to obtain solution A, ultrasonicate for 30 minutes, weigh 3mmol (0.2369g) selenium powder and 10ml hydrazine hydrate, stir for 30 minutes to obtain solution B , Pour solution A into solution B and stir for 30 minutes to obtain a mixed solution, pour the mixed solution into a 50ml polytetrafluoroethylene reactor, react at 120°C for 12 hours to obtain a black product, and use deionized water and absolute ethanol several times Wash, place in a blast drying oven, and dry at 60°C to obtain octahedral NiSe 2 Precursor.

[0028] (2)NiSe 2 / Ni(OH) 2 Preparation of composite material: weigh 100mg NiSe 2 The precursor was dispersed in 20ml of 0.1M / L KOH solution, dispersed evenly by ultrasonication for 5 minutes, then 1ml of 30% hydrogen peroxide was added, and stirred evenly. Pour the above mixed solution into a 50ml polytetrafluoroethylene reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com