Preparation and application of multi-shell CuCo2O4 hollow nanosphere

A hollow nano, cu-co technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of unstable structure, poor conductivity, fast decay in the charging and discharging process, etc., and reach the active site Multiple, mild and controllable reaction conditions, the effect of slowing down the collapse of the electrode material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

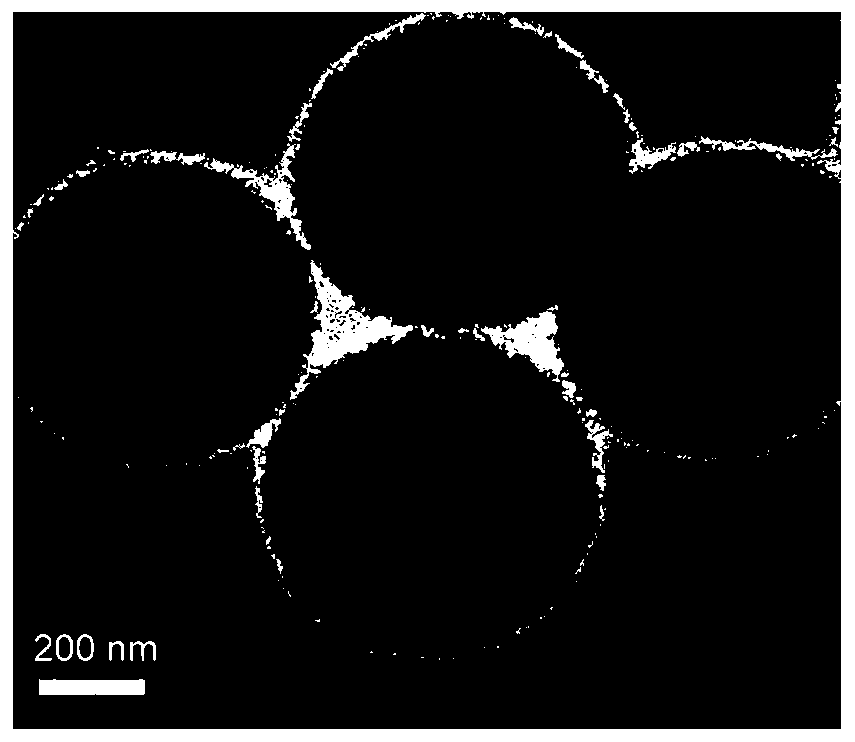

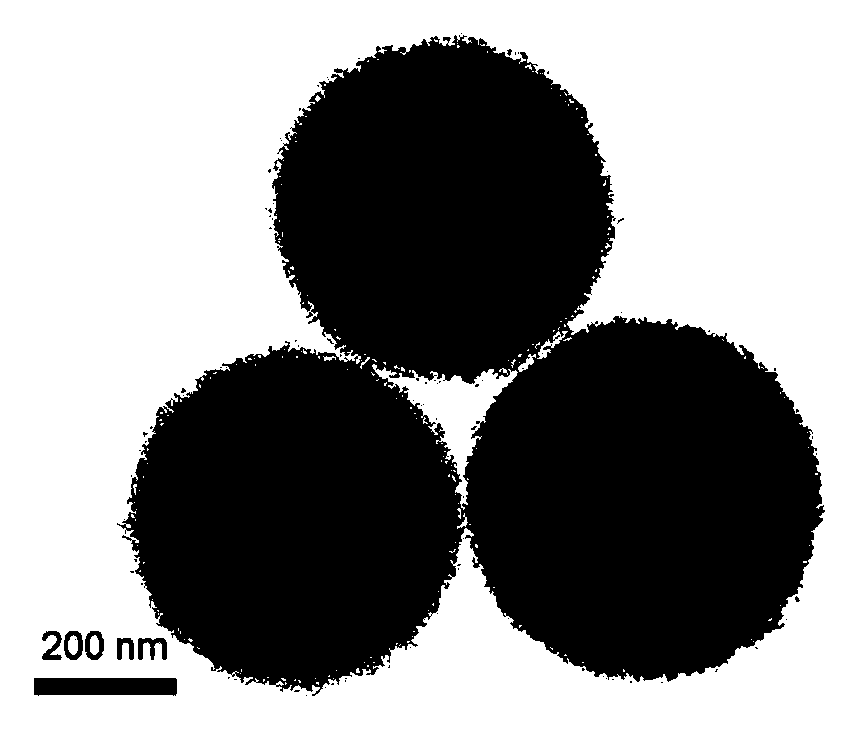

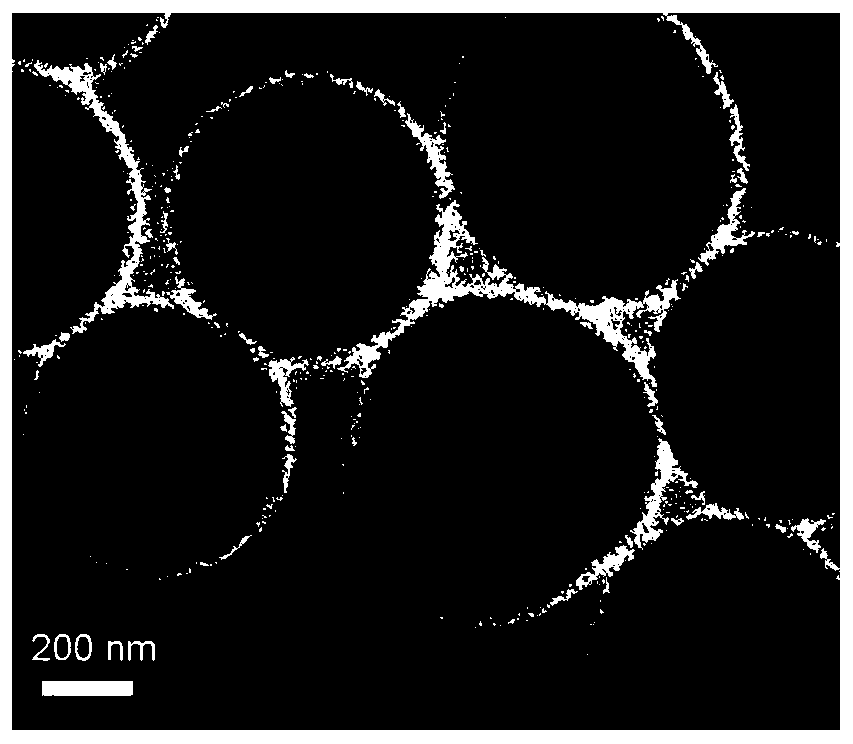

[0038] 1 mmol Co(NO3) 2 ·6H 2 O and 0.5 mmol of Cu(NO 3 ) 2 ·6H 2 O was dissolved in 33.5 ml of isopropanol, 6.5 ml of glycerol was added dropwise to the above solution and stirred for 30 minutes; subsequently, the resulting mixture was transferred to a 50 ml stainless steel autoclave, and reacted at 180°C for 2 hours. The obtained precipitate was collected by centrifugation, washed with absolute ethanol, and dried in an oven at 80° C. for 6 hours to obtain copper alkoxide. Finally, place the copper alkoxide in a muffle furnace for calcination at 300°C for 2 hours, with a heating rate of 2°C / min, and finally obtain CuCo 2 o 4 Hollow core-shell sphere material. CuCo 2 o 4 Powder, PVDF and acetylene black are uniformly mixed at a mass ratio of 8:1:1, and spread on the pretreated foamed nickel, and the mass of the active material is 2mg / cm 2 . The smeared nickel foam is used as an electrode to assemble a supercapacitor.

Embodiment 2

[0040] 1 mmol Co(NO3) 2 ·6H 2 O and 0.5 mmol of Cu(NO 3 ) 2 ·6H 2O was dissolved in 33.5 ml of isopropanol, 6.5 ml of glycerol was added dropwise to the above solution and stirred for 30 minutes; subsequently, the resulting mixture was transferred to a 50 ml stainless steel autoclave, and reacted at 160°C for 4 hours. The obtained precipitate was collected by centrifugation, washed with absolute ethanol, and dried in an oven at 80° C. for 6 hours to obtain copper alkoxide. Finally, place the copper alkoxide in a muffle furnace for calcination at 300°C for 2 hours, with a heating rate of 2°C / min, and finally obtain CuCo 2 o 4 Hollow double shell ball material. CuCo 2 o 4 Powder, PVDF and acetylene black are uniformly mixed at a mass ratio of 8:1:1, and spread on the pretreated foamed nickel, and the mass of the active material is 2mg / cm 2 . The smeared nickel foam is used as an electrode to assemble a supercapacitor.

Embodiment 3

[0042] 1 mmol Co(NO3) 2 ·6H 2 O and 0.5 mmol of Cu(NO 3 ) 2 ·6H 2 O was dissolved in 33.5 ml of isopropanol, 6.5 ml of glycerol was added dropwise to the above solution and stirred for 30 minutes; subsequently, the resulting mixture was transferred to a 50 ml stainless steel autoclave, and reacted at 170°C for 8 hours. The obtained precipitate was collected by centrifugation, washed with absolute ethanol, and dried in an oven at 80° C. for 6 hours to obtain copper alkoxide. Finally, place the copper alkoxide in a muffle furnace for calcination at 300°C for 2 hours, with a heating rate of 2°C / min, and finally obtain CuCo 2 o 4 Hollow three-shell ball material. CuCo 2 o 4 Powder, PVDF and acetylene black are uniformly mixed at a mass ratio of 8:1:1, and spread on the pretreated foamed nickel, and the mass of the active material is 2mg / cm 2 . The smeared nickel foam is used as an electrode to assemble a supercapacitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com