Cathode material, preparation method thereof and lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in the direction of positive electrodes, secondary batteries, battery electrodes, etc., can solve the problems of inability to be covered by materials, many defects, and inability to be covered, and achieve improved liquid retention capacity and high mechanical strength , the effect of great use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

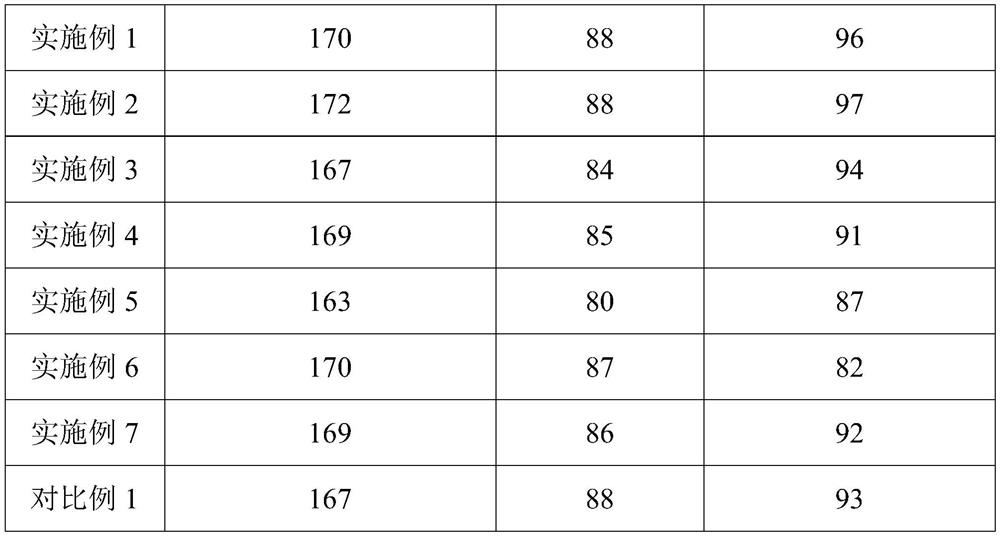

Embodiment 1

[0056] A preparation method of positive electrode material:

[0057] (1) Co(NO 3 ) 2 ·6H 2 The ratio of O and 2-methylimidazole is 1:4 to prepare solutions separately: Co(NO 3 ) 2 ·6H 2 O is dissolved in the mixed solvent of 20mL ethanol+20mL methanol to obtain the first solution, and 2-methylimidazole is dissolved in the mixed solvent of 20mL ethanol+20mL methanol to obtain the second solution;

[0058] (2) then the first solution, the second solution, surfactant (sodium lauryl sulfate) and ammonia (25wt%) were mixed and stirred for 5min to obtain a mixed solution with a pH value of 8, and the surface Active agent mass and Co(NO 3 ) 2 ·6H 2 The mass ratio of O is 1:8;

[0059] Then, the mixed solution was subjected to hydrothermal treatment at a temperature of 100° C. for 48 hours, filtered, and dried to obtain a ZIF-67 precursor;

[0060] (3) Under a nitrogen atmosphere, the ZIF-67 precursor is calcined at a temperature of 800° C. for 12 hours to obtain a dodecahed...

Embodiment 2

[0064] A preparation method of positive electrode material:

[0065] (1) Zn(NO 3 ) 2 ·6H 2 The ratio of O and 2-methylimidazole is 1:4 to prepare solutions respectively: Zn(NO 3 ) 2 ·6H 2 O is dissolved in the mixed solvent of 20mL ethanol+20mL methanol to obtain the first solution, and 2-methylimidazole is dissolved in the mixed solvent of 20mL ethanol+20mL methanol to obtain the second solution;

[0066] (2) then the first solution, the second solution, surfactant (sodium lauryl sulfate) and ammonia (25wt%) were mixed and stirred for 5min to obtain a mixed solution with a pH value of 10, and the surface The quality of active agent and Zn(NO 3 ) 2 ·6H 2 The mass ratio of O is 1:8;

[0067] Then, the mixed solution was subjected to hydrothermal treatment at a temperature of 120° C. for 24 hours, filtered, and dried to obtain a ZIF-8 precursor;

[0068] (3) Under a nitrogen atmosphere, the ZIF-8 precursor is calcined at a temperature of 1200° C. for 8 hours to obtain ...

Embodiment 3

[0072] The difference from Example 1 is that the temperature of the hydrothermal treatment in step (2) is 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com