Metal selenide/c/b composite coated positive electrode material and preparation method thereof

A metal selenide, cathode material technology, applied in battery electrodes, electrochemical generators, structural parts, etc., can solve problems such as poor rate performance of cathode materials, reduce cathode quality, improve rate performance, and solve uneven dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

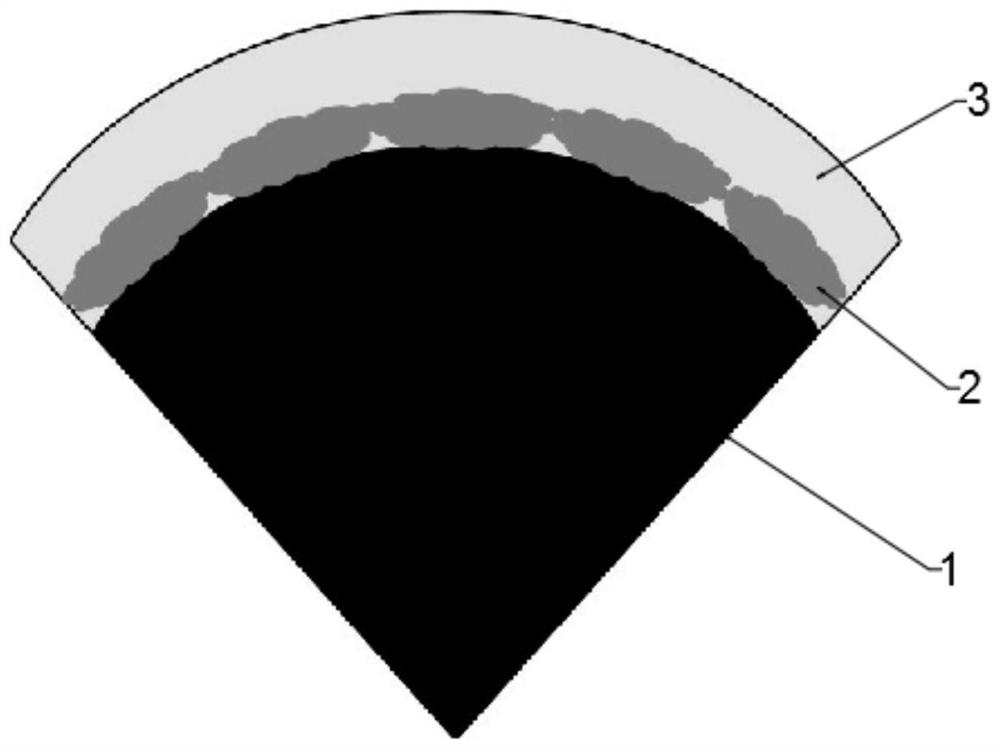

[0021] combined with figure 1 , a kind of preparation method of the cathode material of metal selenide / C / B compound coating, comprises the steps:

[0022] Step S1, mixing nickel salt, cobalt salt and manganese salt in a certain proportion to prepare a ternary precursor solution, adding ammonia water and sodium hydroxide solution to adjust the pH between 10-12, controlling temperature and time, filtering, washing and drying, A nickel-cobalt-manganese ternary precursor is obtained.

[0023] Step S2. After mixing the nickel-cobalt-manganese ternary precursor and lithium salt in a molar ratio, sintering at high temperature, crushing and sieving to obtain a single crystal material.

[0024] In this step, the molar ratio of the nickel-cobalt-manganese ternary precursor mixed with the lithium salt is Li:(Ni+Co+Mn)=1.01-1.08, and the high-temperature sintering temperature is 850-1100°C.

[0025] Step S3, according to a certain addition ratio, add the metal salt to the selenized amin...

Embodiment 1

[0034] 1) Weigh Ni(NO 3 ) 2 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 4H 2 O, and mixed to prepare a ternary precursor solution, adding ammonia water and sodium hydroxide solution to adjust the pH to 11, and adjusting the reaction temperature to 50°C, after the reaction was completed, filtered, washed, and then dried at 80°C for 20h to obtain nickel cobalt manganese three According to the ratio of Li:(Ni+Co+Mn)=1.01, lithium carbonate is added into the precursor, mixed with lithium carbonate, sintered at 850°C, and passed through a 200-mesh sieve to obtain an NCM single crystal material.

[0035] 2) 100g of NCM single crystal material, 5g of indium chloride and 5g of zirconium chloride were added under mechanical stirring into a sufficient amount of selenocysteine solution with a mass fraction of 12wt%, and after most of the solvent was removed by rotary evaporation, the Sinter in a nitrogen environment at 500°C for 8 hours, crush and sieve, add to 200mL aqueous solution of acry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com