A kind of beneficiation method of synchronous dephosphorization and sulfur of high phosphorus sulfur iron ore

A beneficiation method and iron ore technology, applied in flotation, solid separation, etc., can solve the problems of equipment corrosion, complicated process, and large dosage of chemicals, and achieve the effect of low cost, simple operation, and less dosage of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

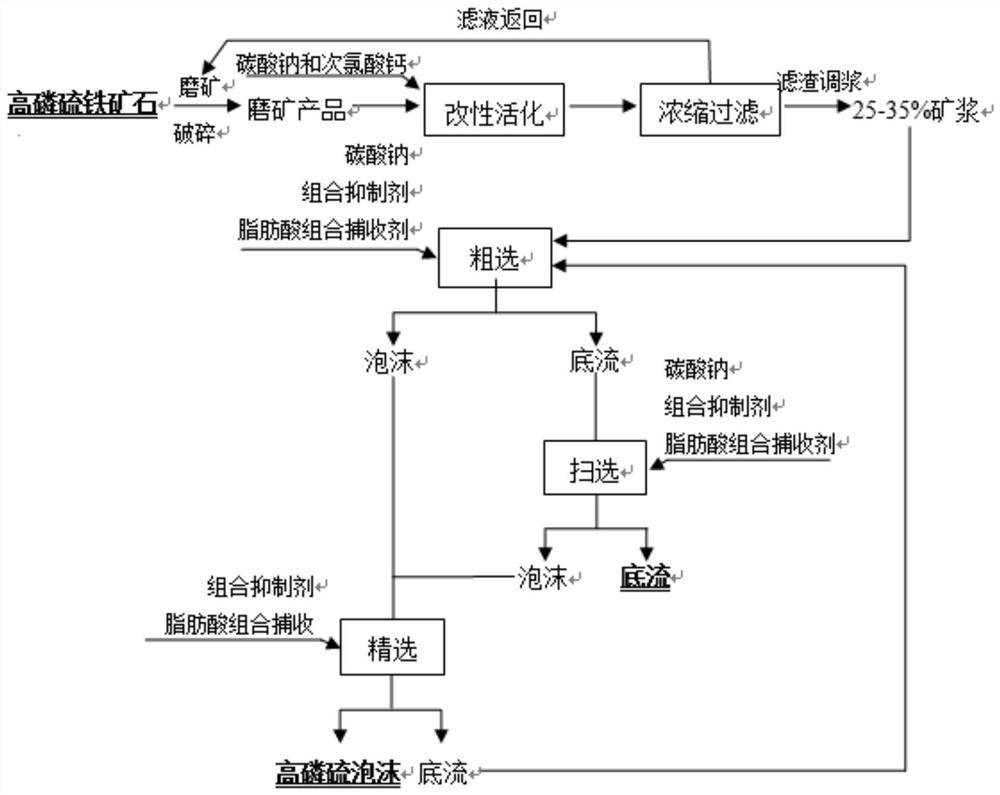

Image

Examples

Embodiment 1

[0028] Siderite ore with 32.6% iron grade, 0.8% phosphorus and 1.0% sulfur is dephosphorized simultaneously.

[0029] (1) Grinding the high phosphorus sulfur siderite ore to -74 μm accounts for 90wt% of the ore material content, and the grinding mass concentration is 65wt%;

[0030] (2) For the grinding product of step (1), adjust slurry to pH 10 with sodium carbonate, add calcium hypochlorite 500g / t, inflate and stir for 30min;

[0031] (3) Concentrating and filtering the high-concentration pulp in step (2) to obtain filtrate and filter residue, the filtrate is returned to the previous step (1) for recycling, and the filter residue is mixed with water until the solid mass concentration is 35wt%;

[0032] (4) Add sodium hydroxide successively to the pulp in step (3), stir for 6 minutes, control the pH value of the pulp solution to be 10, starch and sodium lignosulfonate 500g / t (the molar ratio of the two is 3:1 ), stirring for 8 minutes, sodium oleate and oleic acid amide 800...

Embodiment 2

[0037] Iron grade 37.8%, phosphorus 0.7%, sulfur 0.8% red limonite ore dephosphorization sulfur simultaneously.

[0038] (1) Grinding the high-phosphorus-sulfur hematite ore to -74 μm accounts for 85wt% of the ore material content, and the grinding mass concentration is 60wt%;

[0039] (2) For the grinding product of step (1), adjust slurry to pH9 with sodium carbonate, add calcium hypochlorite 400g / t, inflate and stir for 30min;

[0040] (3) Concentrating and filtering the high-concentration pulp in step (2) to obtain filtrate and filter residue, the filtrate is returned to the previous step (1) for recycling, and the filter residue is mixed with water until the solid mass concentration is 30wt%;

[0041] (4) Add sodium hydroxide successively in the pulp in step (3), stir for 8 minutes, control the pH value of the pulp solution to be 9, starch and sodium lignosulfonate 400g / t (the molar ratio of the two is 4:1 ), stirring for 8 minutes, sodium oleate and oleic acid amide 500...

Embodiment 3

[0046] Magnetite with 42.8% iron grade, 0.8% phosphorus, and 0.6% sulfur is dephosphorized simultaneously.

[0047] (1) Grinding the high-phosphorus-sulfur magnetite to -74 μm accounts for 80wt% of the ore material, and the grinding mass concentration is 60wt%;

[0048] (2) For the grinding product of step (1), adjust slurry to pH 8.5 with sodium carbonate, add calcium hypochlorite 400g / t, inflate and stir for 20min;

[0049] (3) Concentrating and filtering the high-concentration pulp in step (2) to obtain filtrate and filter residue, the filtrate is returned to the previous step (1) for recycling, and the filter residue is mixed with water until the solid mass concentration is 25wt%;

[0050] (4) Add sodium hydroxide successively in the pulp in step (3), stir for 10min, control the pH value of the pulp solution to be 8.5, starch and sodium lignosulfonate 300g / t (the molar ratio of the two is 5:1 ), stirring for 8 minutes, sodium oleate and oleic acid amide 400g / t (the molar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com