Method for preparing lithium hydroxide from waste lithium-ion batteries

A lithium-ion battery, lithium hydroxide technology, applied in the direction of lithium oxide;/hydroxide, etc., can solve the problems of lack of process conditions and process parameters of waste lithium-ion battery, achieve high comprehensive utilization rate, low environmental protection pressure, short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

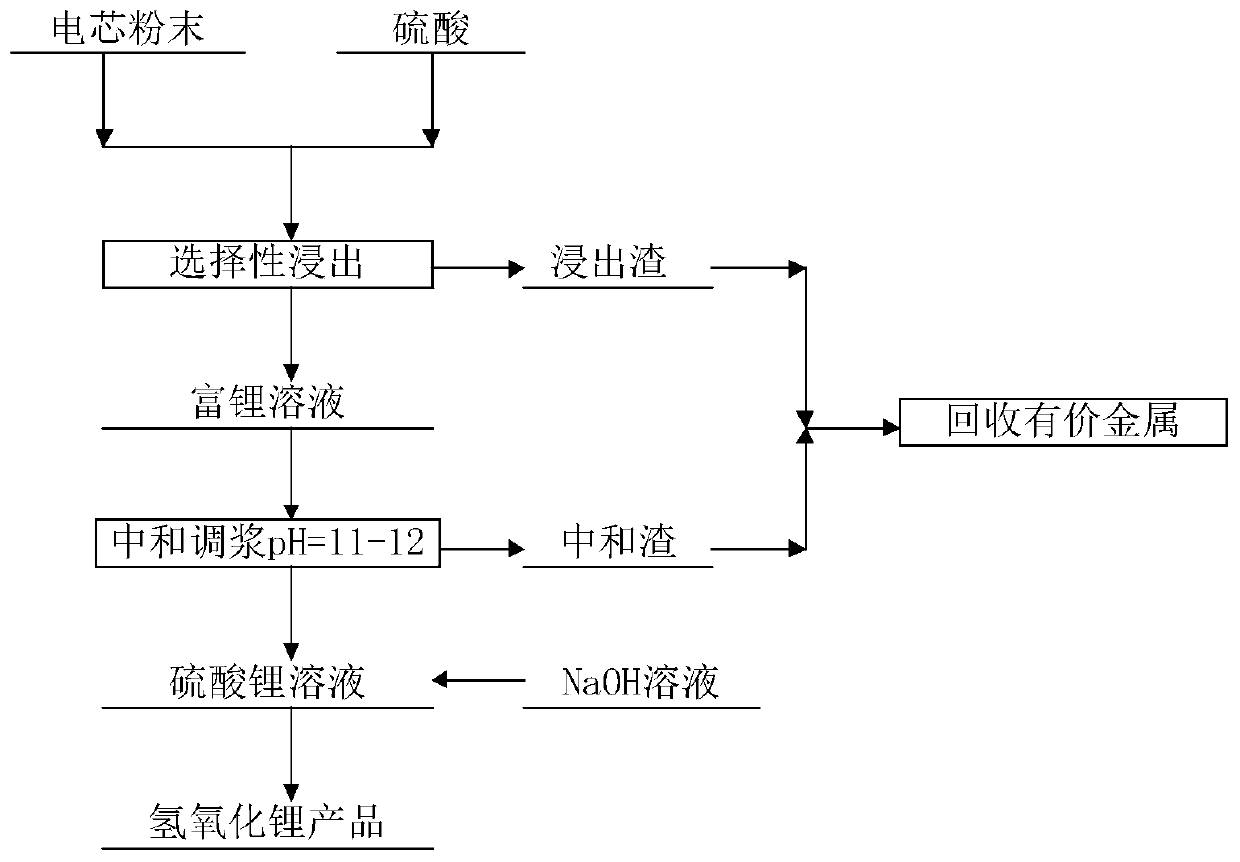

[0032] Embodiment 1: A kind of method utilizing waste lithium ion battery to prepare lithium hydroxide

[0033] Include the following steps in order:

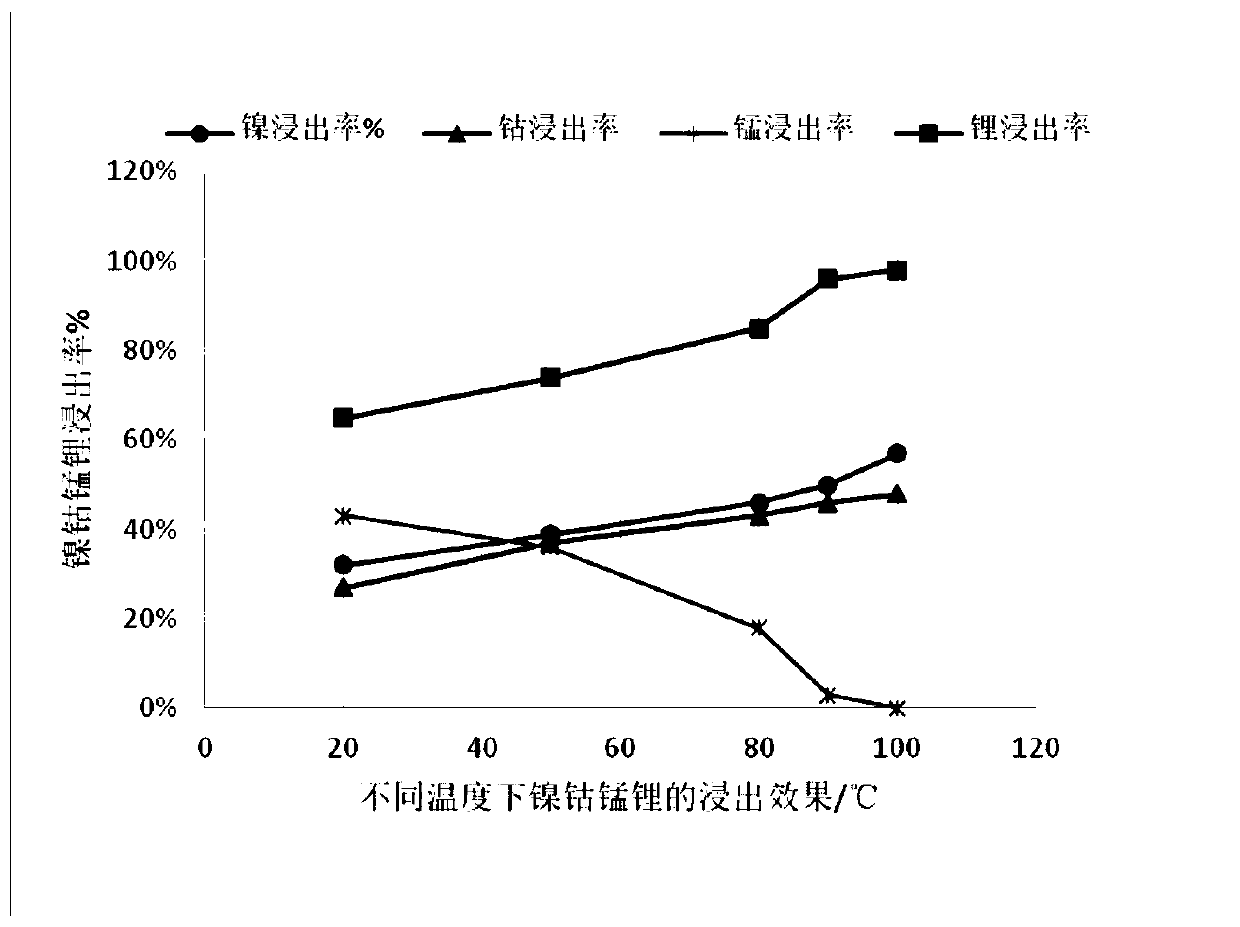

[0034] Take 50g of ternary waste lithium battery cell powder, add 4mol / l sulfuric acid, stir and react at 40°C for 90min, then filter to obtain leaching residue and leaching solution containing nickel-cobalt-manganese-lithium (leaching rate see attached figure 1 ); add sodium hydroxide to the leaching solution, adjust the pH ≈ 11~12, and filter to obtain neutralization slag and lithium sulfate solution.

[0035] According to 0.8 times of the molar theoretical amount of lithium ions, add sodium hydroxide to the purified lithium sulfate solution to obtain sodium sulfate crystals and lithium hydroxide solution; continue to evaporate the lithium hydroxide solution until its solid content reaches 45 to 50 %, cooling to obtain the crude product of lithium hydroxide, and then by means of dissolution-recrystallization, the battery-gra...

Embodiment 2

[0037] Embodiment 2: A kind of method utilizing waste lithium ion battery to prepare lithium ion sieve

[0038] Include the following steps in order:

[0039] Take 50g of ternary waste lithium battery cell powder, add 4mol / l sulfuric acid, stir and react at 60°C for 120min, then filter to obtain leaching residue and leaching solution containing nickel-cobalt-manganese-lithium (leaching rate see attached figure 1 ); add sodium hydroxide to the leaching solution, adjust pH ≈ 11-12, and filter to obtain neutralization slag and lithium sulfate solution.

[0040] According to 1 time of the molar theoretical amount of lithium ions, add sodium hydroxide to the purified lithium sulfate solution, and cool to -8°C under stirring conditions to obtain sodium sulfate crystals and lithium hydroxide solution; continue to evaporate the lithium hydroxide solution, Until its solid content reaches 45-50%, cool to obtain a crude product of lithium hydroxide, and then by means of dissolution-recr...

Embodiment 3

[0041] Example 3: A method for preparing lithium-ion sieves using waste lithium-ion batteries

[0042] Include the following steps in order:

[0043] Take 50g of ternary waste lithium battery cell powder, add 4mol / l sulfuric acid, stir and react at 80°C for 60min, then filter to obtain leaching residue and leaching solution containing nickel-cobalt-manganese-lithium (leaching rate see attached figure 1 ); add sodium hydroxide to the leaching solution, adjust pH ≈ 11-12, and filter to obtain neutralization slag and lithium sulfate solution.

[0044] According to 1.1 times of the molar theoretical amount of lithium ions, sodium hydroxide is added to the purified lithium sulfate solution, cooled to -5°C under stirring conditions, to obtain sodium sulfate crystals and lithium hydroxide solution; continue to evaporate the lithium hydroxide solution, Until its solid content reaches 45-50%, cooling to obtain a crude lithium hydroxide product, and then by means of dissolution-recryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com