HAA (hydroxyalkylamide) cured carboxyl-terminated saturated polyester resin for thermal transfer powder coating and synthesis method of carboxyl-terminated saturated polyester resin

A technology of hydroxyalkylamide and powder coatings, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of low weather resistance, low cross-linking degree of the final coating, poor coating leveling, etc., to achieve flow Pinghe has good mechanical properties, simple resin synthesis process, and no offset printing effect for thermal transfer patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with examples. The examples are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

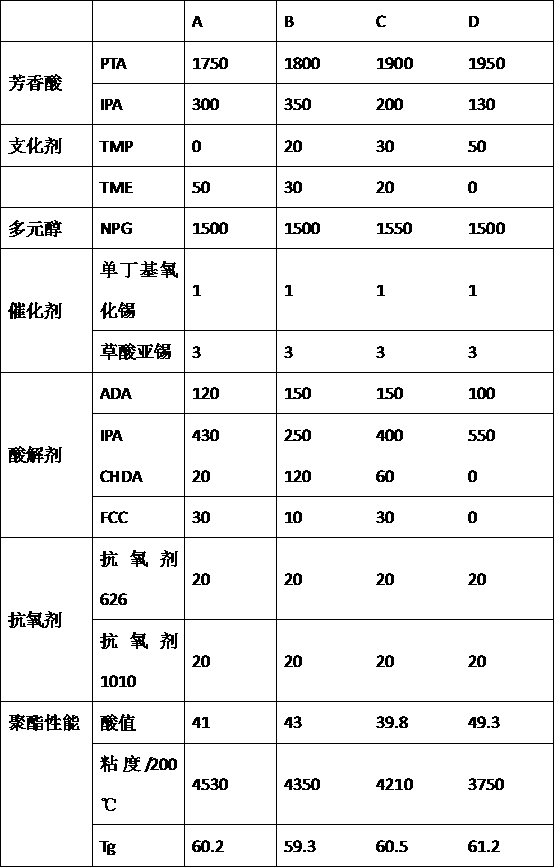

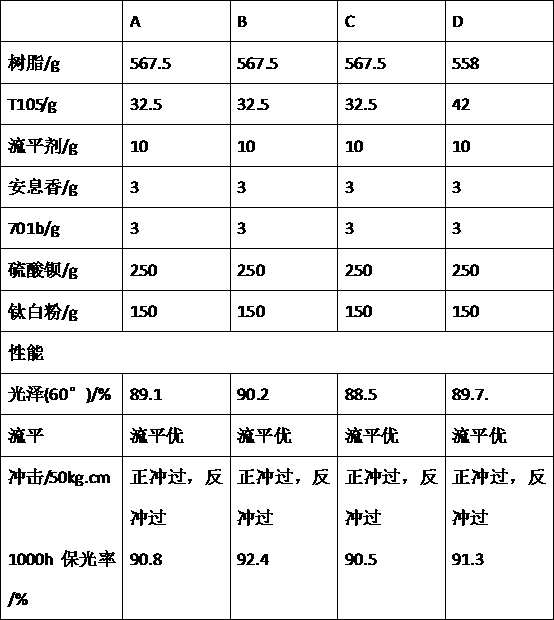

[0024] A part of the specific examples are listed below to illustrate the present invention. In Table 1, A to D are the examples of the present invention and the primary performance of the corresponding polyester resin.

[0025] Preparation method: In a 5 liter glass reactor, add polyols and branching agents in the proportions listed in Table 1 to heat up and melt, then add the corresponding aromatic dibasic acid and catalyst in sequence, and slowly increase the temperature by blowing nitrogen. The system is from 185~ Esterification reaction began to occur at 194℃ and water was discharged, and then gradually heated to 240℃, and reacted for about 3-5h until the system was clear,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com