A kind of polyester resin for indoor low-temperature curing powder coating and preparation method thereof

A powder coating, polyester resin technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problem of poor storage stability of powder coatings, affecting the melting extrusion and storage stability of powder coatings, and the flow of film-forming substances. It can improve the adhesion and chemical properties, excellent storage stability and good storage stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a kind of polyester resin for indoor low-temperature curing powder coating, which polyester resin is composed of these raw materials of polybasic acid, polyhydric alcohol, branching agent, acidolysis agent, esterification catalyst, antioxidant and curing accelerator , through the synthesis process, vacuuming process, acid hydrolysis process, and compounding process, the milky white translucent semi-crystalline polyester resin is synthesized.

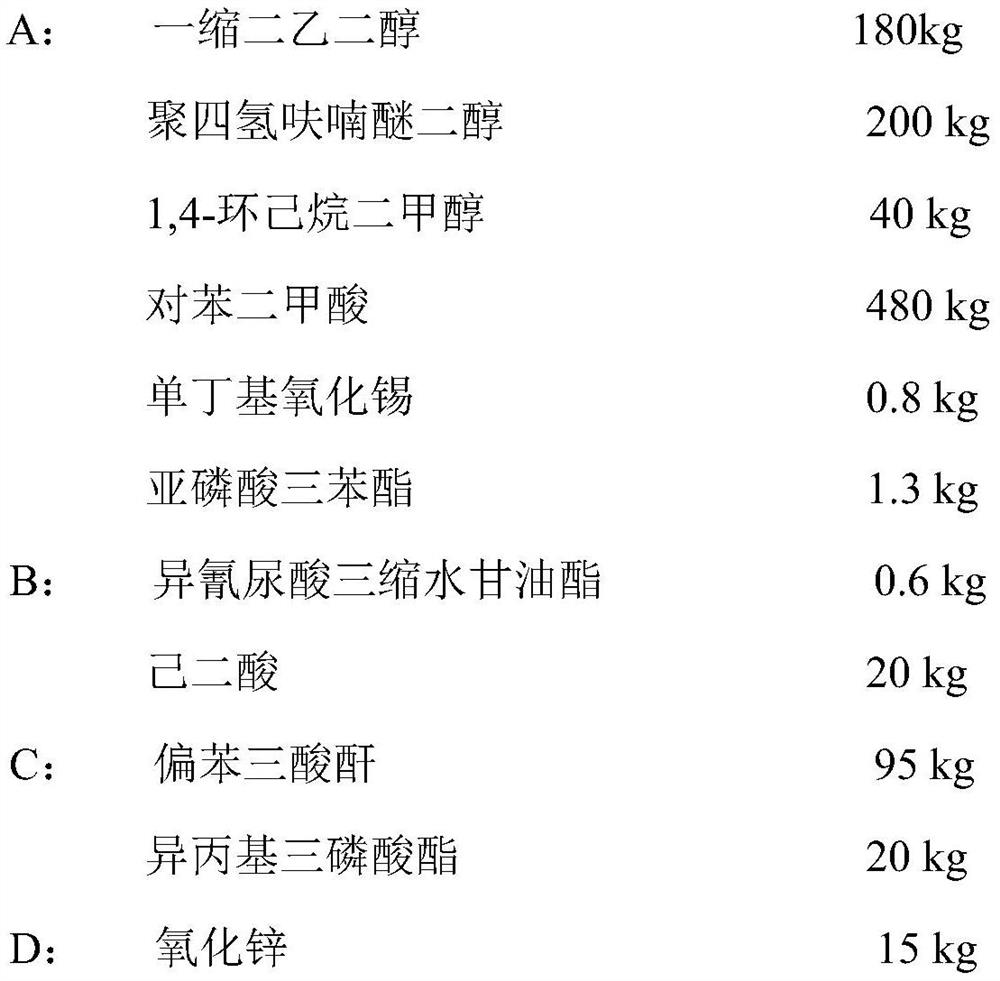

[0028] Wherein, the specific synthetic formula is as follows:

[0029]

[0030] The preparation method of above-mentioned indoor low-temperature curing powder coating polyester resin is specifically as follows:

[0031] (1) Synthesis process: first put the polyol in component A into the reaction kettle, heat up to a molten state (90-100°C), add terephthalic acid in component A, and then add monobutyltin oxide and For triphenyl phosphite, seal the kettle and raise the temperature to the reflux temperatu...

Embodiment 2

[0036] This embodiment This embodiment provides a polyester resin for indoor low-temperature curing powder coatings. These raw materials are synthesized into a milky white translucent semi-crystalline polyester resin through a synthesis process, a vacuum process, an acid hydrolysis process, and a compounding process.

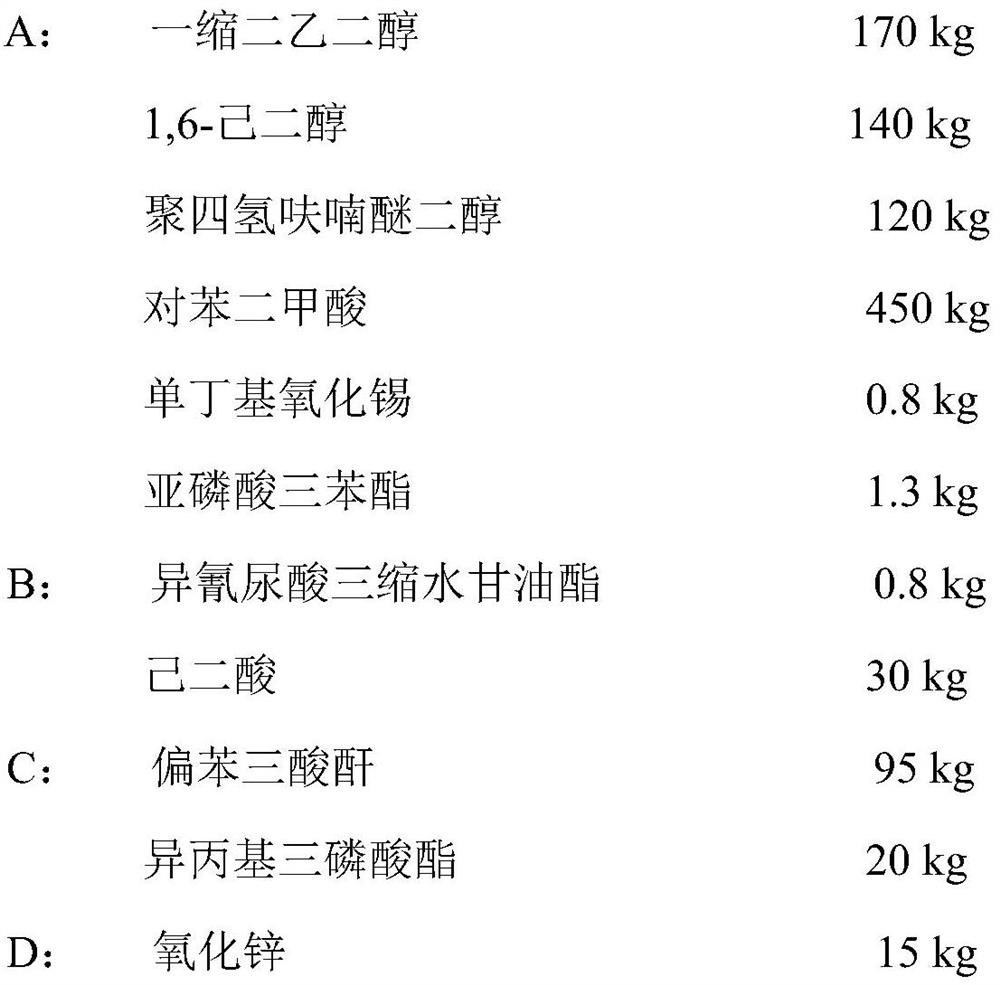

[0037] Wherein, the specific synthetic formula is as follows:

[0038]

[0039] The preparation method of the above-mentioned indoor low-temperature curing powder coating polyester resin is the same as in Example 1.

Embodiment 3

[0041] This embodiment This embodiment provides a polyester resin for indoor low-temperature curing powder coatings. These raw materials are synthesized into a milky white translucent semi-crystalline polyester resin through a synthesis process, a vacuum process, an acid hydrolysis process, and a compounding process.

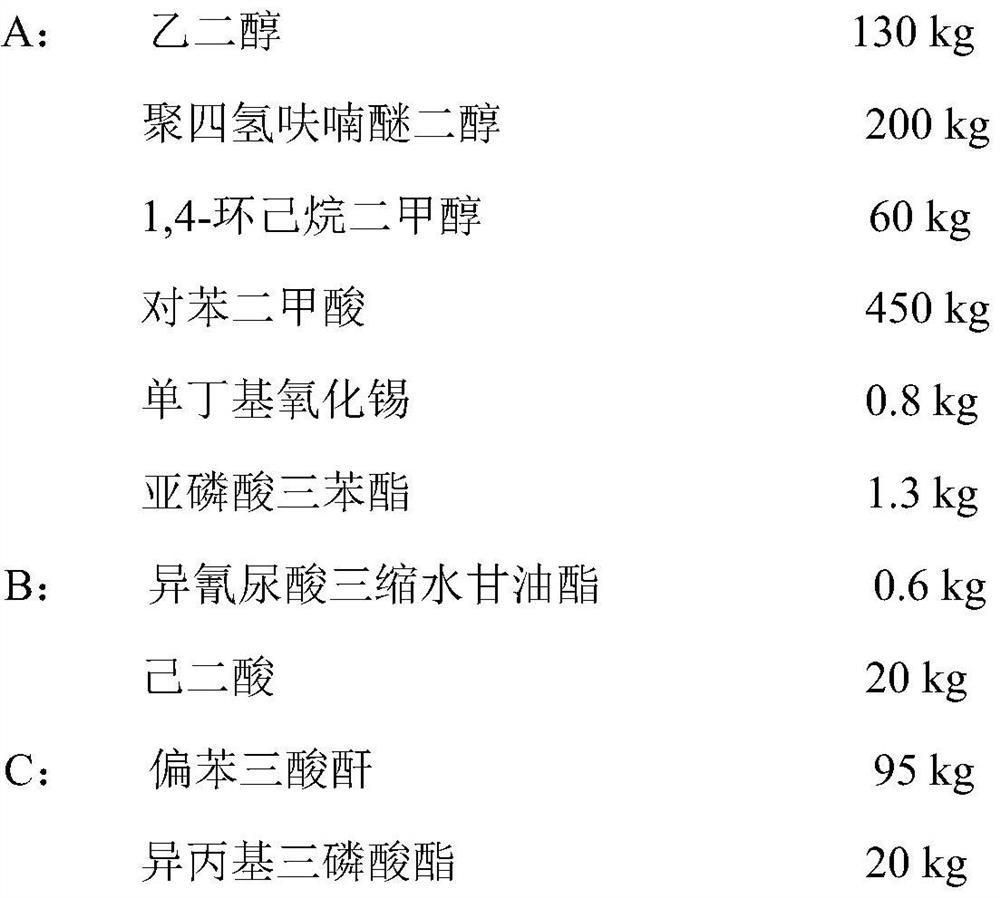

[0042] Wherein, the specific synthetic formula is as follows:

[0043]

[0044]

[0045] The preparation method of the above-mentioned indoor low-temperature curing powder coating polyester resin is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com