Two-dimensional nanosheet-polymer flexible composite film and preparation method thereof

A two-dimensional nano-composite thin film technology, which is applied in the field of dielectric composite material manufacturing, can solve the problems of reduced breakdown field strength of composite thin films and reduced flexibility of composite materials, and achieve excellent mechanical and electrical properties, high dielectric constant, The effect of improving the breakdown field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

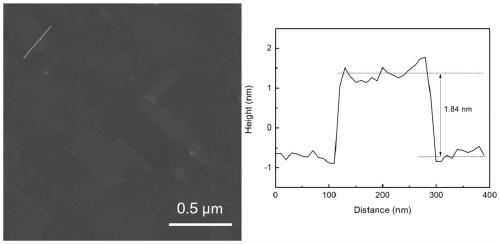

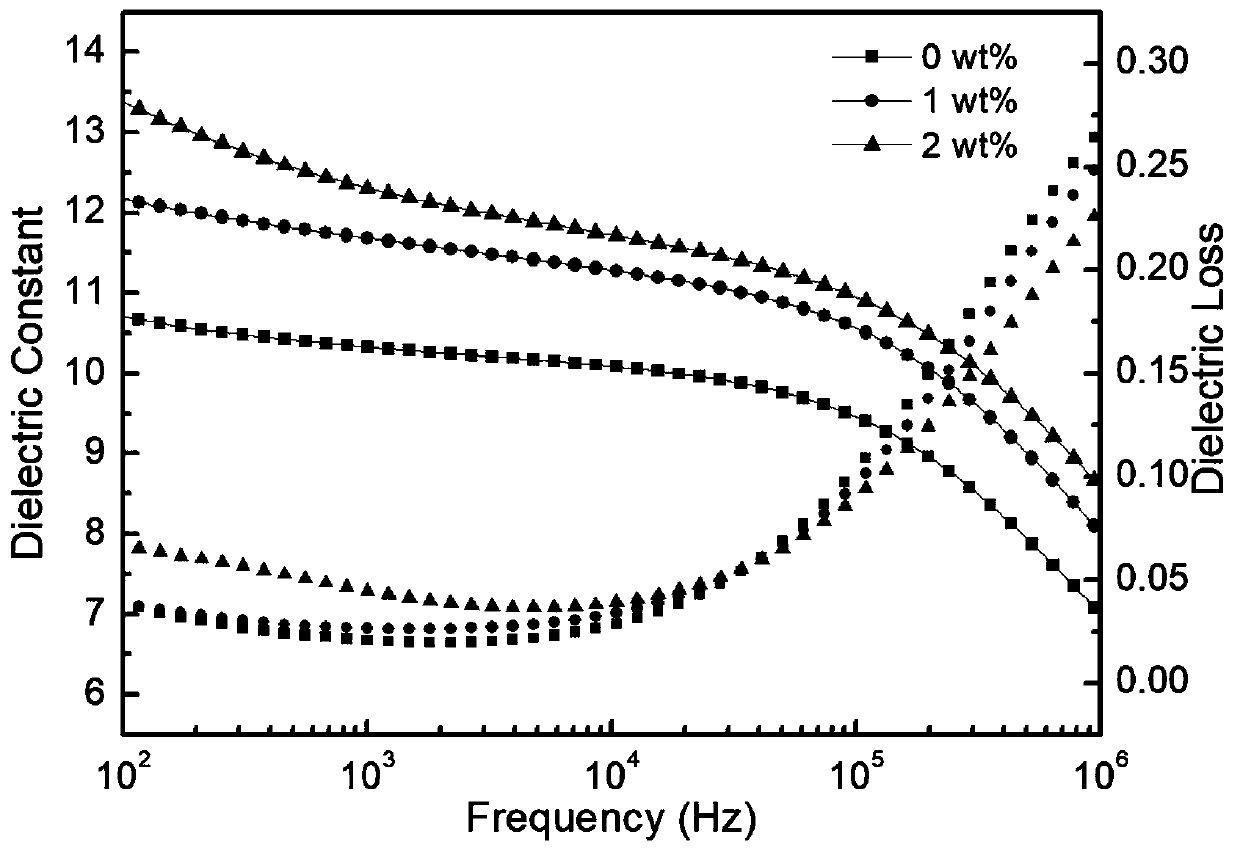

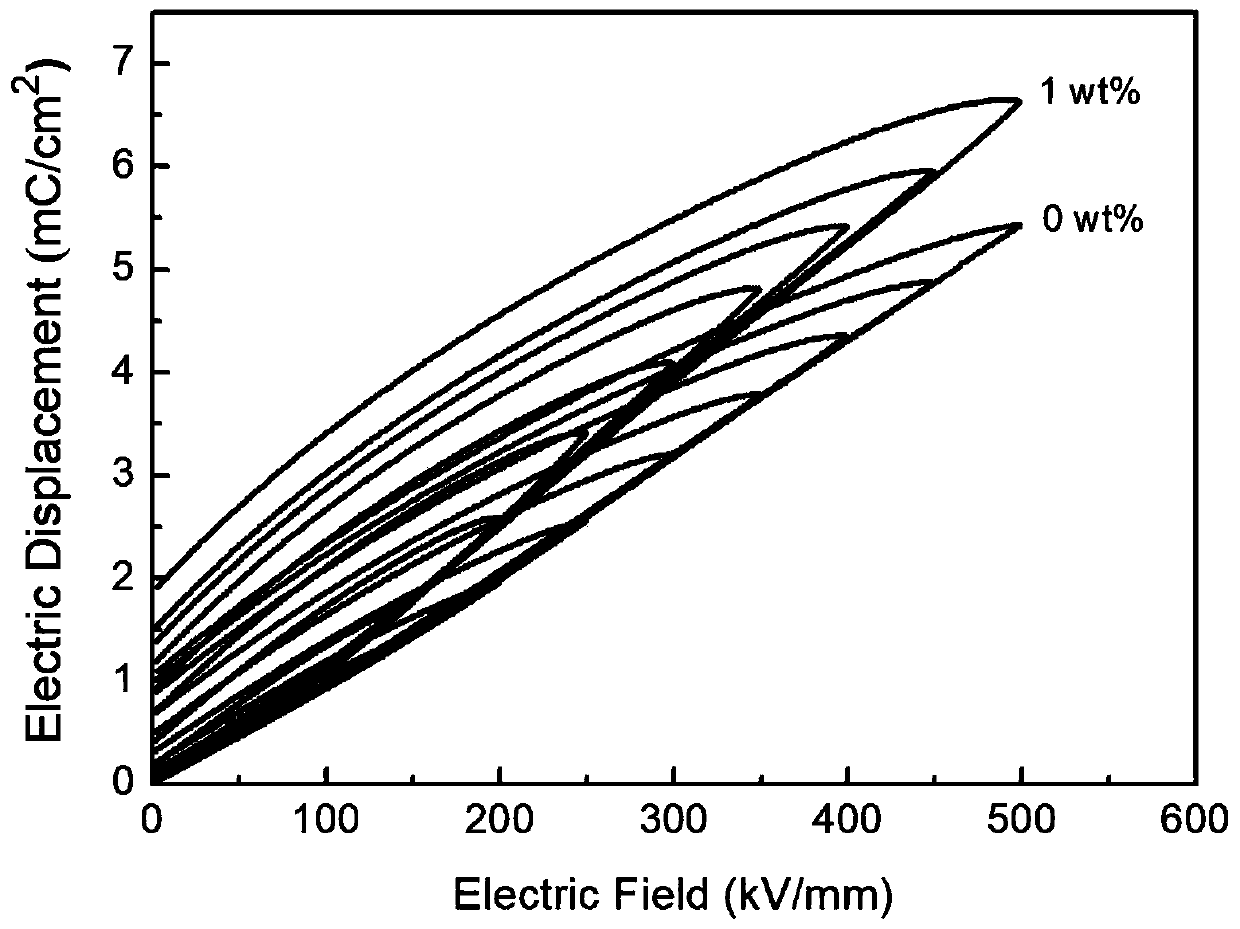

[0031] Example 1, see Figure 1 to Figure 4 :

[0032] The invention provides a two-dimensional nanosheet-polymer flexible composite film, and a preparation method comprising the following steps:

[0033] 1) Preparation of HCa with perovskite structure 2 Nb 3 o 10 Two-dimensional nanosheets:

[0034] a) Weigh 1.4558g potassium carbonate (K 2 CO 3 ), 4.0164g calcium carbonate (CaCO 3 ) and 8.000g niobium pentoxide (Nb 2 o 5 ) was ground in an agate mortar for 60 min, and then calcined in a high temperature furnace at 1200 °C for 12 h to obtain KCa 2 Nb 3 o 10 sample;

[0035] b) Weigh 2.5g of synthetic KCa 2 Nb 3 o 10 Powder is placed in the Erlenmeyer flask that 100ml nitric acid (5mol / L) is housed, and Erlenmeyer flask is fixed on the vibration 72h on the small shaker, after proton exchange reaction finishes, filter, the sample that obtains is washed with ultrapure water (resistivity greater than 18MΩ) to wash off the residual nitric acid on the surface, and o...

Embodiment 2

[0040] Example 2, see figure 2 :

[0041] The raw materials and preparation process of this embodiment are basically the same as in Example 1, the difference is that in step d), 2ml of the emulsion after the stripping of the two-dimensional nanosheets is measured, and the finished product is a two-dimensional nanosheet with a filler of 2%. Nanosheet-polymer flexible composite films.

Embodiment 3

[0049] The raw materials and preparation process of this example are basically the same as those of Example 1, except that the polymer is PVDF-HFP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com