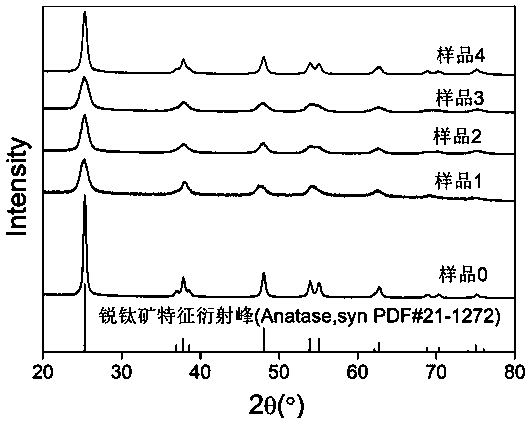

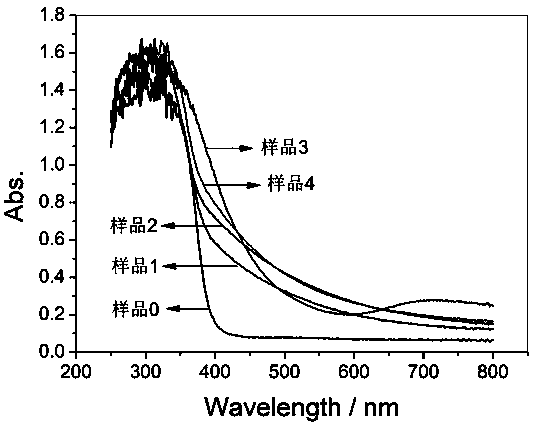

TiO2 photocatalyst doped with C and N for improving activity of visible light and preparation method of photocatalyst

A photocatalyst and co-doping technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of narrow visible light response range, pollution of photocatalyst preparation methods, harsh preparation conditions, etc. Achieve the effect of increasing absorption and response intensity, reducing energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 0.80g soybean protein isolate powder to the polytetrafluoroethylene lining of the reaction kettle, then add 50ml ethanol and 5ml distilled water, seal it and place it in a 160°C thermostat for 12 hours, cool to room temperature, and filter the residue to obtain a brownish red color water / alcoholysis reaction solution; take 3ml of the above-mentioned brown-red water / alcoholysis reaction solution and add it to 12ml ethanol to obtain 15ml diluted water / alcoholysis reaction solution; take 25m ethanol at room temperature, and slowly add 8ml titanic acid while stirring Add 18ml of dilute water / alcoholysis solution reaction solution drop by drop after butyl ester, fully stir the reaction for 2h to obtain a light yellow sol, then slowly add 40ml of water / alcoholysis solution reaction solution, stir and age for 4h; add 100ml of water In a thermal reaction kettle, seal it and react in a constant temperature box at 200°C for 24 hours; cool to room temperature, centrifuge to obt...

Embodiment 2

[0033] Add 1.0g soybean protein isolate powder to the polytetrafluoroethylene lining of the reaction kettle, then add 60ml ethanol and 10ml distilled water, seal it and place it in a 160°C thermostat for 24 hours, cool to room temperature, and filter the residue to obtain a brownish red color Take 2ml of the above-mentioned brown-red liquid and add it to 10ml ethanol to obtain 12ml diluted water / alcoholysis solution reaction solution; take 15m ethanol at room temperature, slowly add 5ml butyl titanate while stirring, and then gradually Add 12ml of diluted water / alcoholysis solution reaction solution dropwise, fully stir the reaction for 2h to obtain a light yellow sol, then slowly add 50ml of water / alcoholysis solution reaction solution, stir and age for 8h; put it into a 100ml hydrothermal reaction kettle, After sealing, react in a constant temperature box at 220°C for 24 hours; cool to room temperature, and centrifuge to obtain light yellow solid powder, wash with ethanol and...

Embodiment 3

[0038] Add 1.2g soybean protein isolate powder to the polytetrafluoroethylene lining of the reaction kettle, then add 50ml ethanol and 10ml distilled water, seal it and place it in a 180°C thermostat for 24 hours, cool to room temperature, and filter the residue to obtain a brownish red color Take 1ml of the above-mentioned brown-red liquid and add it to 10ml ethanol to obtain 11ml diluted water / alcoholysis solution reaction solution; take 15m ethanol at room temperature, slowly add 5ml butyl titanate while stirring, and then gradually Add 11ml of diluted water / alcoholysis solution reaction solution dropwise, fully stir the reaction for 2h to obtain a light yellow sol, then slowly add 50ml of water / alcoholysis solution reaction solution, stir and age for 12h; put it into a 100ml hydrothermal reaction kettle, After sealing, react in a constant temperature box at 180°C for 24 hours; cool to room temperature, centrifuge to obtain a golden yellow solid powder, wash with ethanol and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com