A kind of preparation method of hierarchical porous zsm-5 nano-aggregate

A technology of ZSM-5 and agglomerates, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of increased energy consumption, large zeolite size, and poor uniformity. Achieve the effects of reducing production energy consumption, reducing the generation of miscellaneous crystals, and accelerating the growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of MFI nanostructure microcrystalline liquid

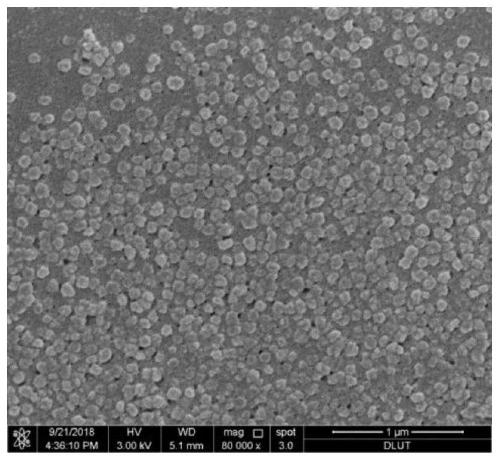

[0031] Mole ratio TPAOH:TEOS:H 2 O: EtOH=7.5:28:360:1000, 24.7mlTPAOH, 4mlH 2 O, 23.6ml EtOH and 25.8ml TEOS were mixed uniformly at room temperature; then loaded into a polytetrafluoroethylene-lined kettle, statically crystallized in an oven at 80°C for 3 days, cooled to room temperature, and MFI microcrystalline liquid with a size of no more than 80nm was obtained.

[0032] (2) Preparation of hierarchically porous ZSM-5 aggregates in a template-free system

[0033] According to the molar ratio of alkali source, silicon source, aluminum source, potassium dihydrogen phosphate and water 9.5:100:2.86:10.8:2126, 0.43g sodium metaaluminate, 0.47g sodium hydroxide, 1.34g potassium dihydrogen phosphate, Added into 24.3ml of deionized water, mechanically stirred at room temperature for 30min to a clear state; then added 15.4ml of silica sol, stirred at room temperature for 30min, added 0.5wt% microcrystalline liq...

Embodiment 2

[0035] (1) The preparation method of the MFI nanostructure microcrystalline liquid is the same as that in Example 1.

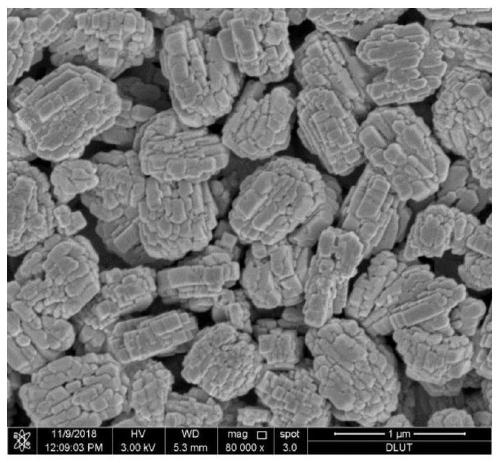

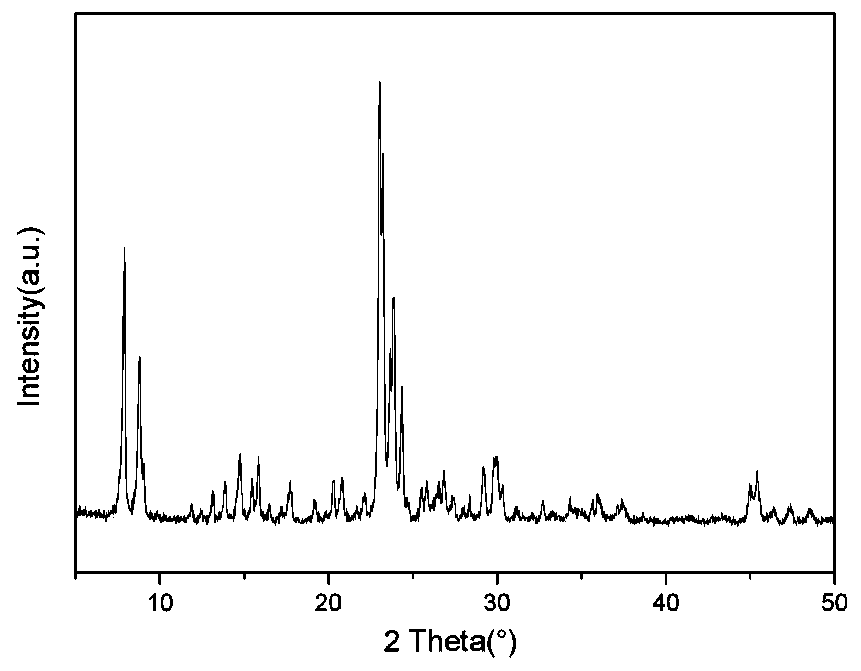

[0036](2) According to the molar ratio of alkali source, silicon source, aluminum source, potassium dihydrogen phosphate and water 9.5:100:2.86:21.6:2126, 0.43g sodium metaaluminate, 0.47g sodium hydroxide, 2.68g diphosphate Potassium hydrogen was added to 24.3ml of deionized water, stirred mechanically at room temperature for 30min to a clear state; then added 15.4ml of silica sol, stirred at room temperature for 30min, then added 0.5% wt of the seed liquid synthesized in step (1), and aged for 1h to Gel state; put into polytetrafluoroethylene-lined kettle; static crystallization at 60°C for 4 hours, then static crystallization at 170°C for 8 hours; cool to room temperature, centrifuge, wash until neutral; then dry in an oven at 100°C After 6h, hierarchical porous ZSM-5 nanoaggregates were obtained. The yield of the synthesized sample is 94.4%; the aggregate...

Embodiment 3

[0038] (1) Preparation of MFI nanostructure microcrystalline liquid

[0039] Mole ratio TPAOH:TEOS:H 2 O: EtOH=7.5:28:360:1000, 24.7mlTPAOH, 4mlH 2 O, 23.6ml of EtOH and 25.8ml of TEOS were mixed uniformly at room temperature; then loaded into a polytetrafluoroethylene-lined kettle, statically crystallized in an oven at 60°C for 5 days, cooled to room temperature, and MFI microcrystalline liquid with a size of no more than 80nm was obtained.

[0040] (2) According to the molar ratio of alkali source, silicon source, aluminum source, potassium dihydrogen phosphate and water 12:100:2.5:32.4:1063, 0.38g sodium metaaluminate, 0.59g sodium hydroxide, 4.02g diphosphate Potassium hydrogen was added to 12.1ml of deionized water, stirred mechanically at room temperature for 30min to a clear state; then added 15.4ml of silica sol, stirred at room temperature for 30min, then added 0.5wt% of the seed liquid synthesized in step (1), and aged for 1h to Gel state; put into a polytetrafluor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com