Environment-friendly high-performance friction material for automobile brake pad and preparation method thereof

A technology for friction materials and brake pads, which is applied in the field of environmentally friendly high-performance friction materials for automobile brake pads and its preparation, can solve problems such as oxidation, endangering the ecological environment, and damaging human organs, and achieves easy operation and preparation technology Simple, low-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] 1. A method for preparing an environmentally friendly high-performance friction material for an automobile brake pad:

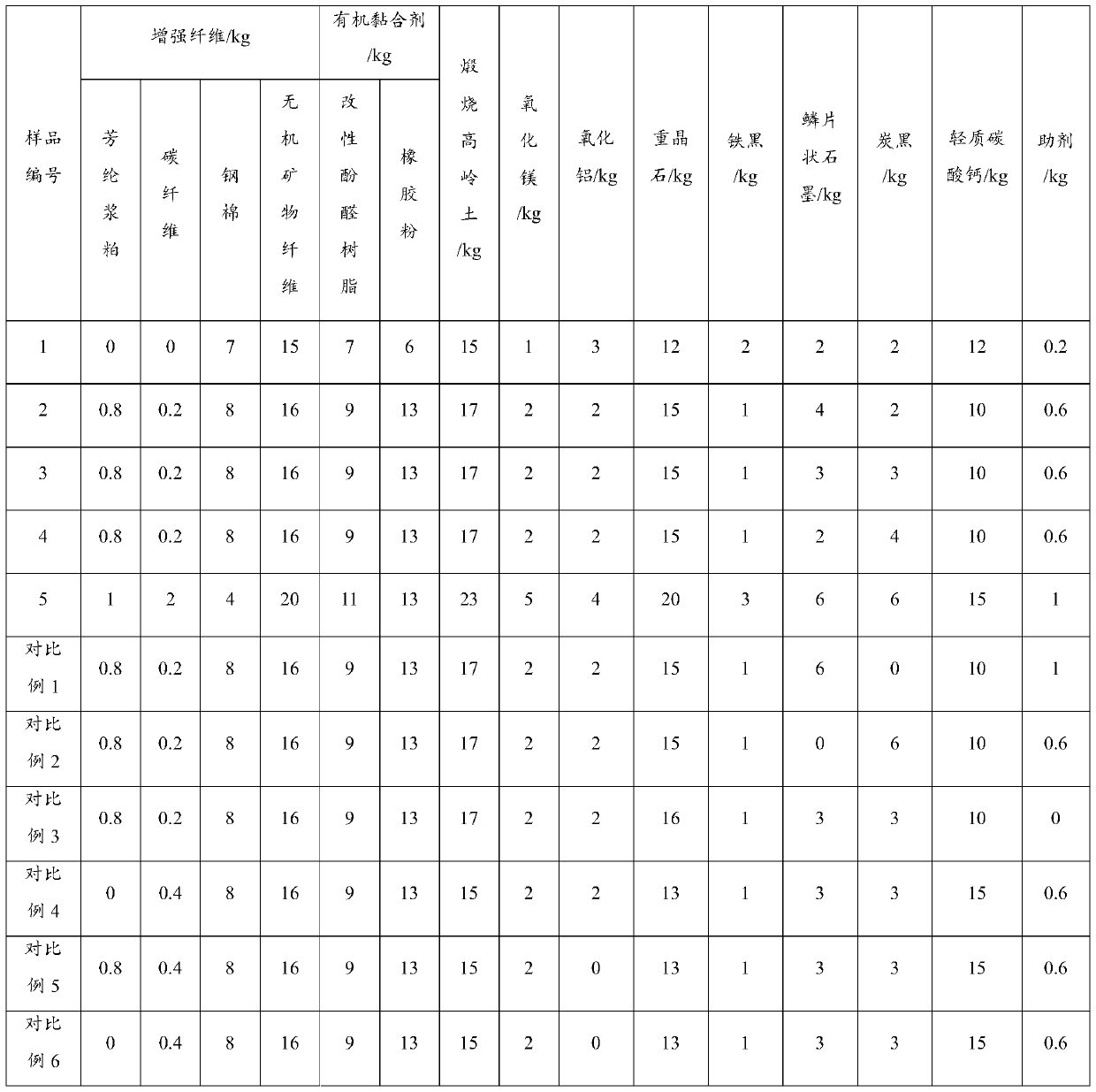

[0027] S1. Mixing: First put 22-27 parts of reinforcing fiber and 13-24 parts of organic binder into a high-speed mixer and mix until uniform; then add 15-23 parts of calcined kaolin; 1-5 parts of magnesium oxide; 2 -4 parts of alumina; 12-20 parts of barite; 1-3 parts of iron black; 2-6 parts of flake graphite; 2-6 parts of carbon black; 10-15 parts of light calcium carbonate ; 0.2-1 parts of additives are put into a high-speed mixer and fully mixed to obtain a uniformly mixed molding material;

[0028] S2. Drying: Put the molded material in S1 in an electric heating constant temperature blast drying oven for drying treatment, the drying temperature is 95-105°C, and the drying time is 3-4h;

[0029]S3. Hot pressing: add the molding material after drying in S2 into the mold and mold it to obtain the friction plate to be processed. The molding temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com