Preparation method of highly stable oral mucosa repair material

A technology for oral mucosa and repair materials, applied in the field of medical materials, can solve problems such as poor hydrophilicity, flexibility and stability, and poor biocompatibility, achieve complex shapes, improve mechanical properties, and shorten the duration of oral ulcers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

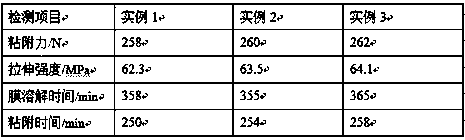

Examples

example 1

[0027] According to the mass ratio of 1:10, add propolis to 70% ethanol solution with mass fraction, stir and mix and extract twice at 55°C, control the single extraction time to 20h, and filter and collect after the extraction is completed Filtrate, place the filtrate at 75°C and 0.02MPa under reduced pressure and evaporate to 1 / 5 of the original volume to obtain a rotary evaporated liquid and vacuum freeze-dry, grind at room temperature through a 200-mesh sieve to obtain abrasive particles, calculated in parts by weight , respectively weigh 45 parts of chloroform, 4 parts of absolute ethanol and 6 parts of grinding particles and place them in the Erlenmeyer flask, stir and mix and dropwise add 1% mass fraction of sodium hydroxide solution to the Erlenmeyer flask to control the amount of sodium hydroxide solution added The mass is the same as that of chloroform, and the dropping rate is 1mL / min. After the dropwise addition is completed, add 1% hydrochloric acid dropwise to the...

example 2

[0029] According to the mass ratio of 1:10, add propolis to 70% ethanol solution by mass fraction, stir and mix and extract twice at 57°C, and control the single extraction time to 22h. After the extraction is completed, filter and collect Filtrate, place the filtrate at 77°C and 0.03MPa under reduced pressure and evaporate to 1 / 5 of the original volume to obtain a rotary evaporated liquid and vacuum freeze-dry, grind at room temperature through a 200-mesh sieve to obtain abrasive particles, calculated in parts by weight , respectively weigh 47 parts of chloroform, 4 parts of absolute ethanol and 7 parts of grinding particles and place them in the Erlenmeyer flask, stir and mix and dropwise add mass fraction 1% sodium hydroxide solution to the Erlenmeyer flask to control the amount of sodium hydroxide solution added The mass is the same as chloroform, and the dropping rate is 2mL / min. After the dropwise addition is completed, add 1% hydrochloric acid dropwise to the Erlenmeyer ...

example 3

[0031] According to the mass ratio of 1:10, add propolis to 70% ethanol solution by mass fraction, stir and mix and extract 3 times at 60°C, and control the single extraction time to 24h. After the extraction is completed, filter and collect Filtrate, place the filtrate at 80°C and 0.05MPa under reduced pressure and evaporate to 1 / 5 of the original volume, obtain a rotary evaporated liquid and vacuum freeze-dry, grind at room temperature through a 200-mesh sieve to obtain abrasive particles, calculated in parts by weight , respectively weigh 50 parts of chloroform, 5 parts of absolute ethanol and 8 parts of grinding particles and place them in the Erlenmeyer flask, stir and mix and dropwise add 1% mass fraction of sodium hydroxide solution to the Erlenmeyer flask to control the amount of sodium hydroxide solution added The mass is the same as that of chloroform, and the dropping rate is 2mL / min. After the dropwise addition is completed, add 1% hydrochloric acid dropwise to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com