Collagen dressing containing PCL microspheres and preparation method and 3D printing application thereof

A collagen and microsphere technology, used in medical science, bandages, additive processing, etc., can solve the problems of complex process, harsh preparation conditions, wound infection, etc., to improve porosity and air permeability, and promote wound repair and healing. , the effect of high mechanical properties and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

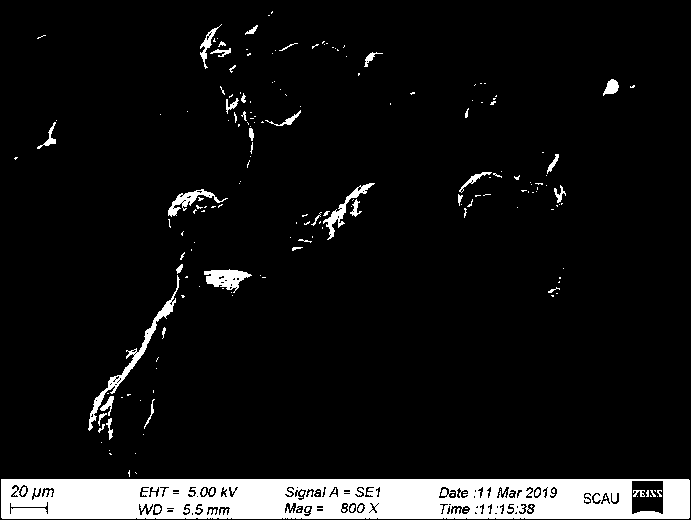

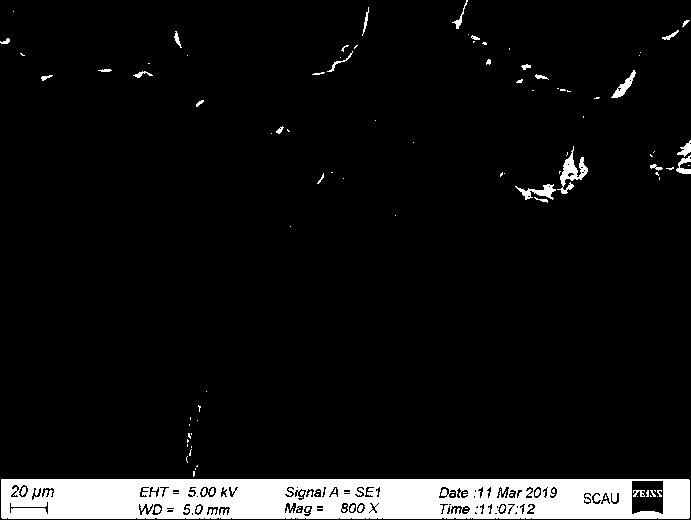

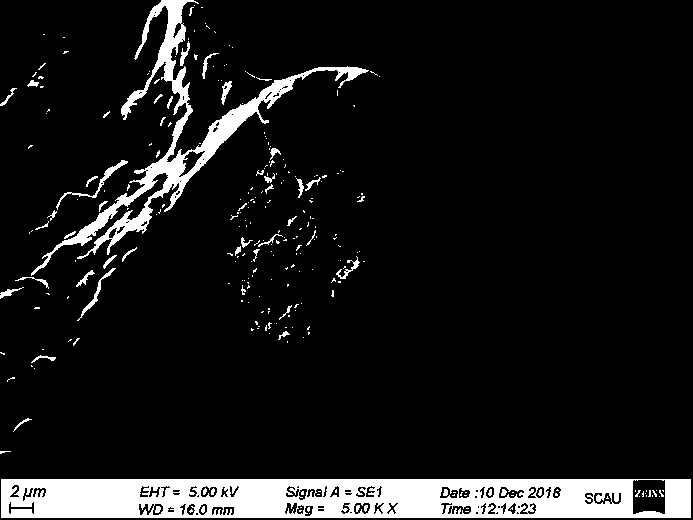

Image

Examples

Embodiment 1

[0026] A preparation method for 3D printing a collagen dressing containing PCL microspheres, comprising the following steps:

[0027] (1) Weigh 0.06 g of enrofloxacin and 0.225 g of polycaprolactone (PCL) into 3 ml of dichloromethane, and ultrasonically disperse at room temperature for 20 minutes to form an oil phase; in addition, weigh 0.3 g of hydroxyapatite Add HAP to 9 mL of deionized water, stir and disperse at room temperature for 30 min to form a water phase; use a pipette to measure the above oil phase and add it to the water phase (the ratio between the water phase and the oil phase is 3 : 1), use a vortex mixer to shake for 10 min to form an oil-in-water emulsion;

[0028] (2) Pour the oil-in-water emulsion obtained in the above step (1) into a petri dish, let the dichloromethane volatilize naturally for 24 hours, and finally obtain white powdery PCL drug-loaded microspheres;

[0029] (3) Weigh 0.3 g of collagen, 0.6 g of hydroxyapatite (HAP), and 1.2 g of sodium al...

Embodiment 2

[0032] A preparation method for 3D printing a collagen dressing containing PCL microspheres, comprising the following steps:

[0033] (1) Weigh 0.06 g of enrofloxacin and 0.225 g of polycaprolactone (PCL) into 3 ml of dichloromethane, and ultrasonically disperse at room temperature for 20 minutes to form an oil phase; in addition, weigh 0.3 g of hydroxyapatite Add HAP to 9 mL of deionized water, stir and disperse at room temperature for 30 min to form a water phase; use a pipette to measure the above oil phase and add it to the water phase (the ratio between the water phase and the oil phase is 3 : 1), use a vortex mixer to shake for 10 min to form an oil-in-water emulsion;

[0034] (2) Pour the oil-in-water emulsion obtained in the above step (1) into a petri dish, let the dichloromethane volatilize naturally for 24 hours, and finally obtain white powdery PCL drug-loaded microspheres;

[0035] (3) Weigh 0.3 g of collagen, 0.6 g of hydroxyapatite (HAP), and 1.5 g of sodium al...

Embodiment 3

[0038] A preparation method for 3D printing a collagen dressing containing PCL microspheres, comprising the following steps:

[0039](1) Weigh 0.06 g of enrofloxacin and 0.225 g of polycaprolactone (PCL) into 3 ml of dichloromethane, and ultrasonically disperse at room temperature for 20 minutes to form an oil phase; in addition, weigh 0.3 g of hydroxyapatite Add HAP to 9 mL of deionized water, stir and disperse at room temperature for 30 min to form a water phase; use a pipette to measure the above oil phase and add it to the water phase (the ratio between the water phase and the oil phase is 3 : 1), use a vortex mixer to shake for 10 min to form an oil-in-water emulsion;

[0040] (2) Pour the oil-in-water emulsion obtained in the above step (1) into a petri dish, let the dichloromethane volatilize naturally for 24 hours, and finally obtain white powdery PCL drug-loaded microspheres;

[0041] (3) Weigh 0.3 g of collagen, 0.6 g of hydroxyapatite (HAP), and 1.8 g of sodium alg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com