Catalyst for decomposing formaldehyde and preparation method of catalyst

A catalyst and formaldehyde technology are applied in the field of catalyst for decomposing formaldehyde and its preparation, which can solve the problems of poor plasticity and low formaldehyde purification efficiency, and achieve the effects of improving catalytic efficiency, increasing surface area and improving purification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

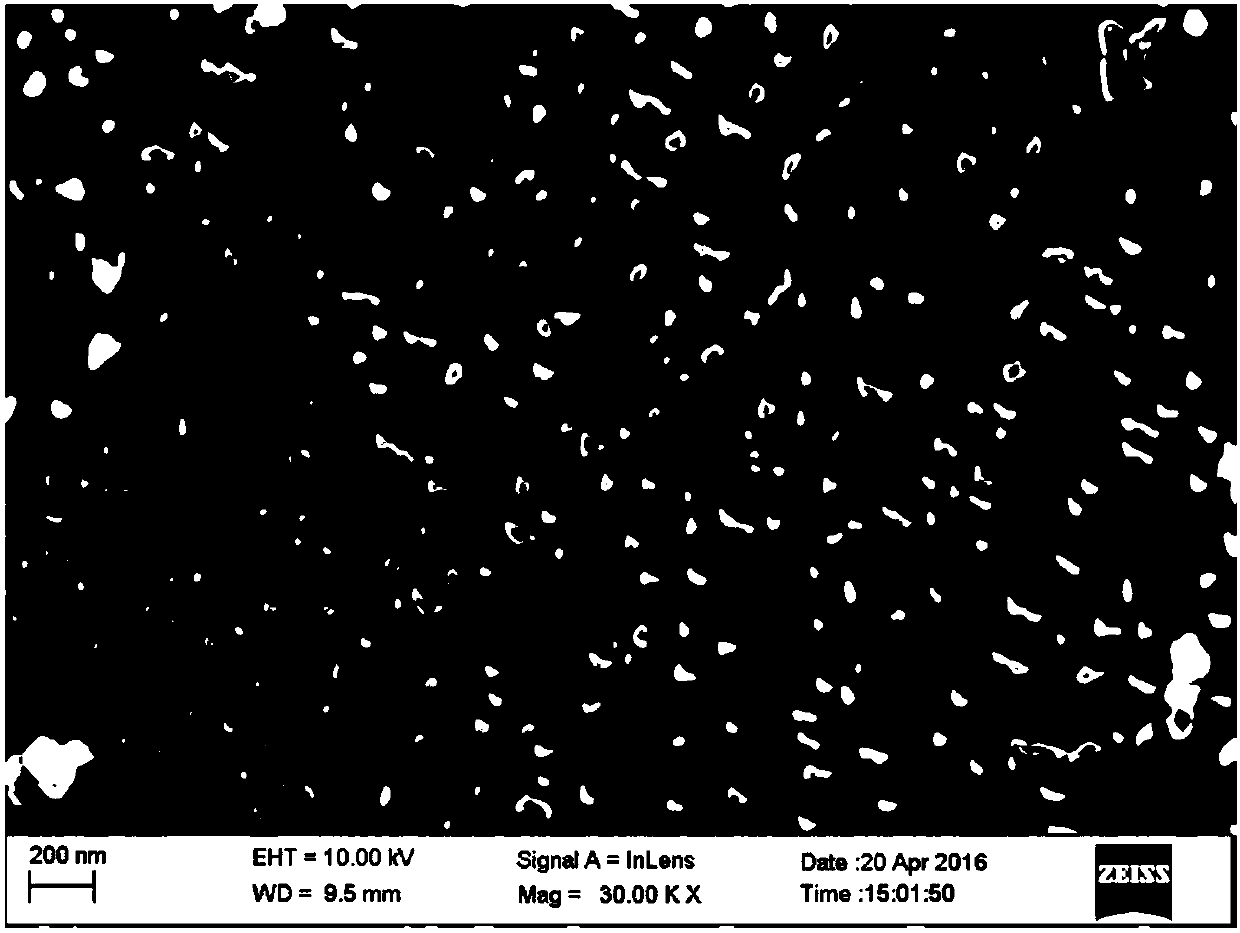

[0031] According to one embodiment of the catalyst of the present invention, the noble metal nanoparticles are preferably platinum nanoparticles.

[0032] Platinum nanoparticles are loaded on the titanium dioxide film of the titanium mesh, which has a better catalytic effect on the decomposition of formaldehyde. Of course, other noble metal nanoparticles, such as palladium nanoparticles, can also be used.

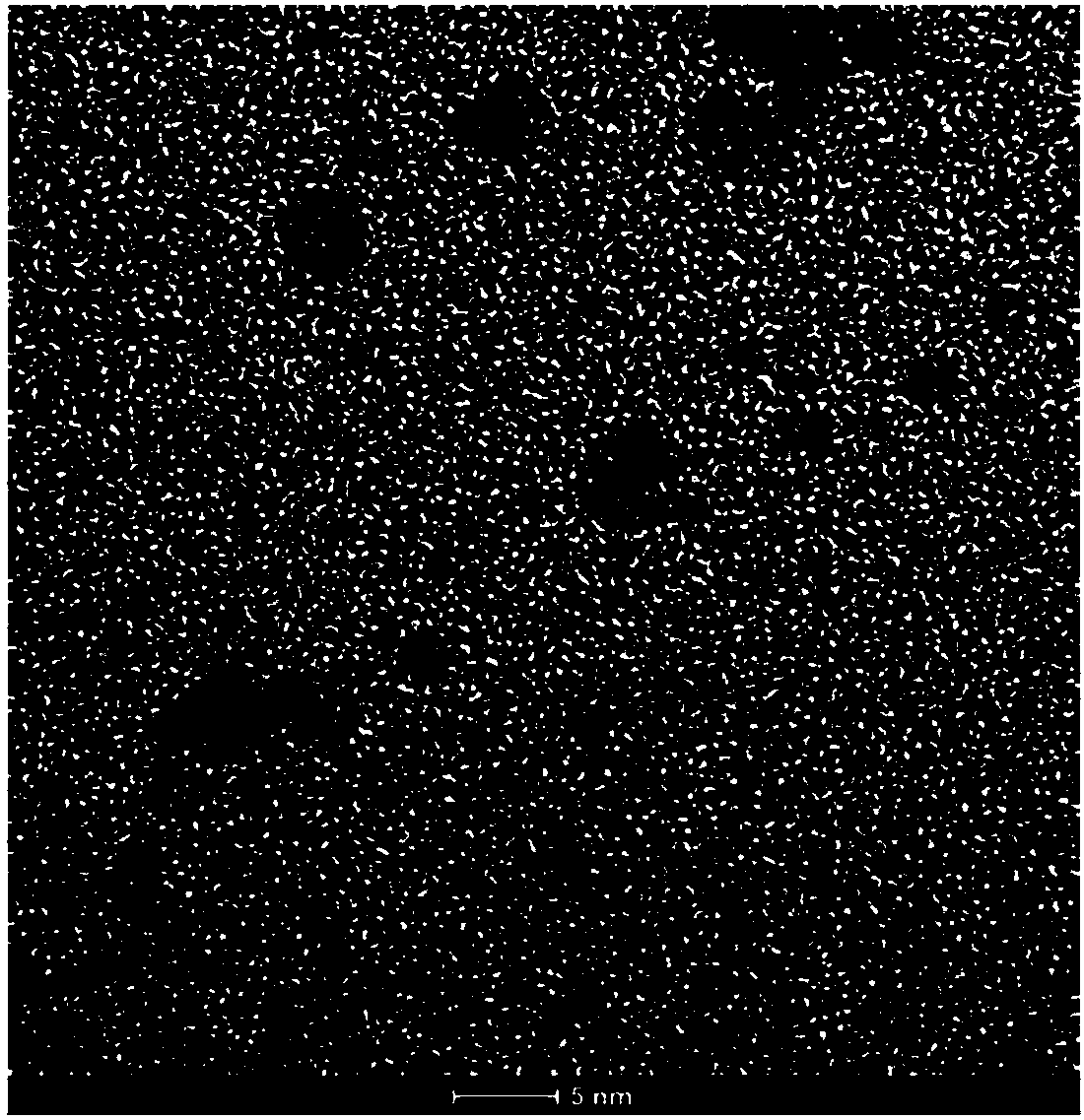

[0033] According to one embodiment of the catalyst of the present invention, the particle size of the platinum nanoparticles is preferably 4-6 nm.

[0034] The particle size of the platinum nanoparticles is 4-6nm, and the particle size is small, which increases the number of catalytic sites, improves the catalytic efficiency, and further improves the purification rate of formaldehyde.

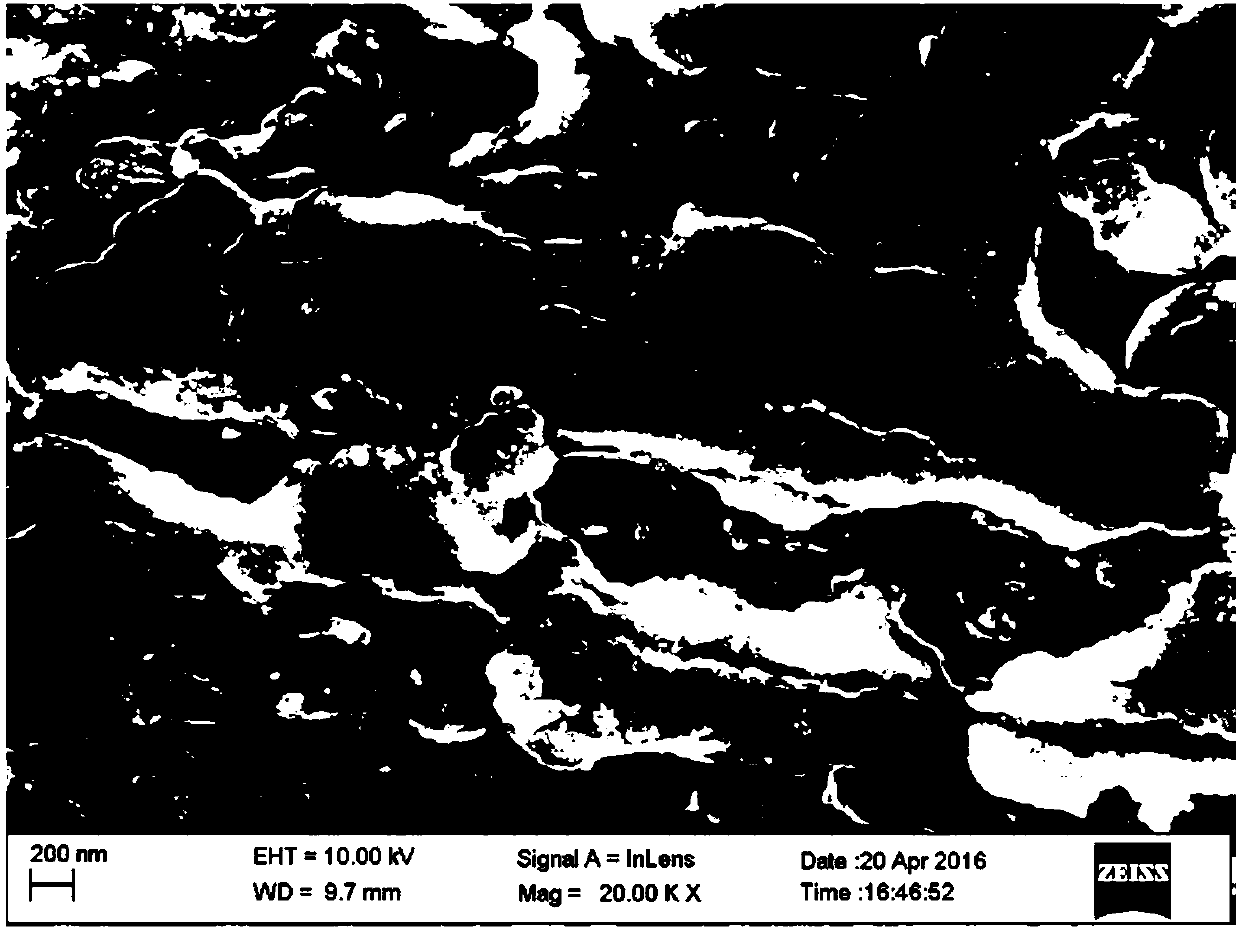

[0035] According to one embodiment of the catalyst of the present invention, the mesh size of the titanium gauze is 20-100 mesh.

[0036] According to another aspect of the present inventio...

Embodiment 1

[0048] In the preparation method of this example, the pretreatment step of the titanium screen is firstly carried out: soak the titanium screen in the mixed acid solution for 5 minutes, place it in deionized water for ultrasonic cleaning for 30 minutes, take it out and dry it at 50° C. for 6 hours; wherein, The mixed acid is prepared by mixing hydrofluoric acid and nitric acid at a volume ratio of 1:1, the mass percentage concentration of hydrofluoric acid is 3%, and the mass percentage concentration of nitric acid is 15%; the preparation step of carrying out the titanium dioxide film: the titanium wire mesh Carry out calcination, the calcination temperature is 300°C, and the calcination time is 2h, so that the surface of the titanium mesh forms a titanium dioxide film; then proceed to the preparation step of noble metal nanoparticles: under the protection of the protective agent, use the reducing agent to reduce the noble metal compound to the noble metal nanometer Particles, ...

Embodiment 2

[0050] In the preparation method of this example, the pretreatment step of the titanium screen is firstly carried out: soak the titanium screen in the mixed acid solution for 15 minutes, place it in deionized water and ultrasonically clean it for 60 minutes, and dry it at 70° C. for 8 hours after taking it out; , the mixed acid is prepared by mixing hydrofluoric acid and nitric acid at a volume ratio of 2:1, the mass percentage concentration of hydrofluoric acid is 5%, and the mass percentage concentration of nitric acid is 30%; The screen is calcined, the calcining temperature is 500°C, and the calcining time is 6h, so that the surface of the titanium screen forms a titanium dioxide film; after that, the preparation step of noble metal nanoparticles is carried out: under the protection of the protective agent, the noble metal compound is reduced to Noble metal nanoparticles, and form noble metal nanoparticle colloids, the noble metal nanoparticles are platinum nanoparticles, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com