Preparation method of elastic double crosslinked aerogel

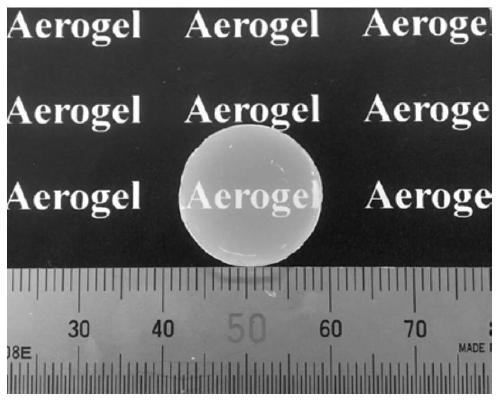

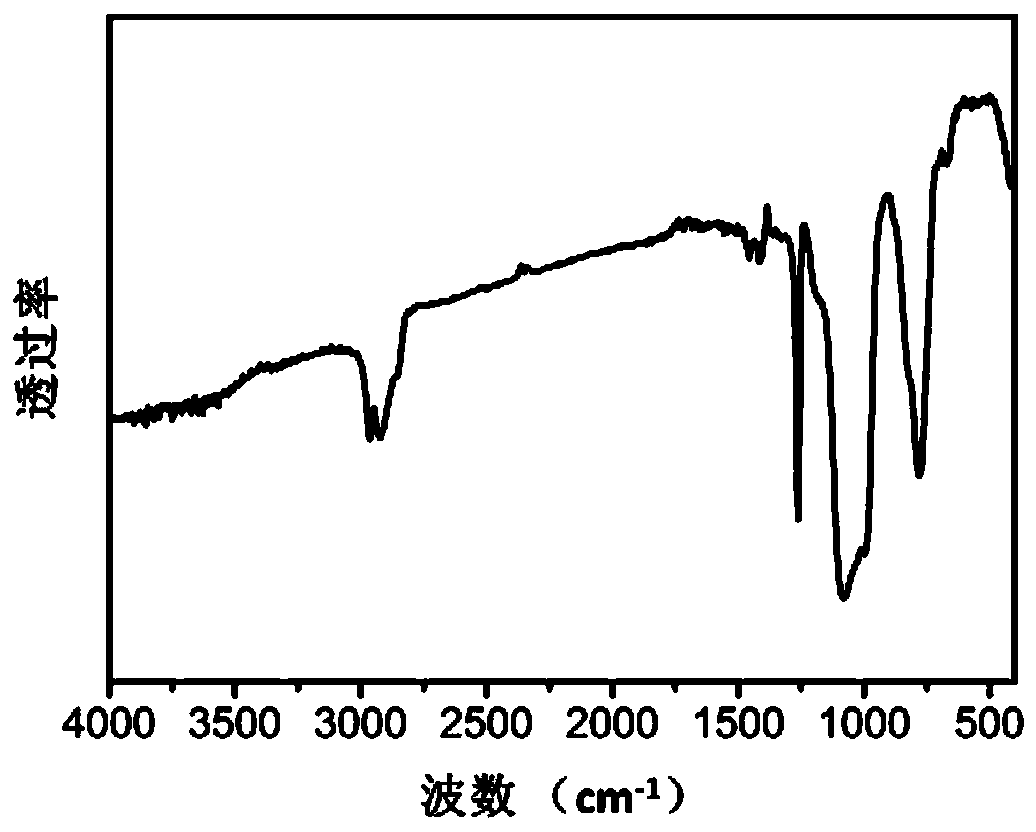

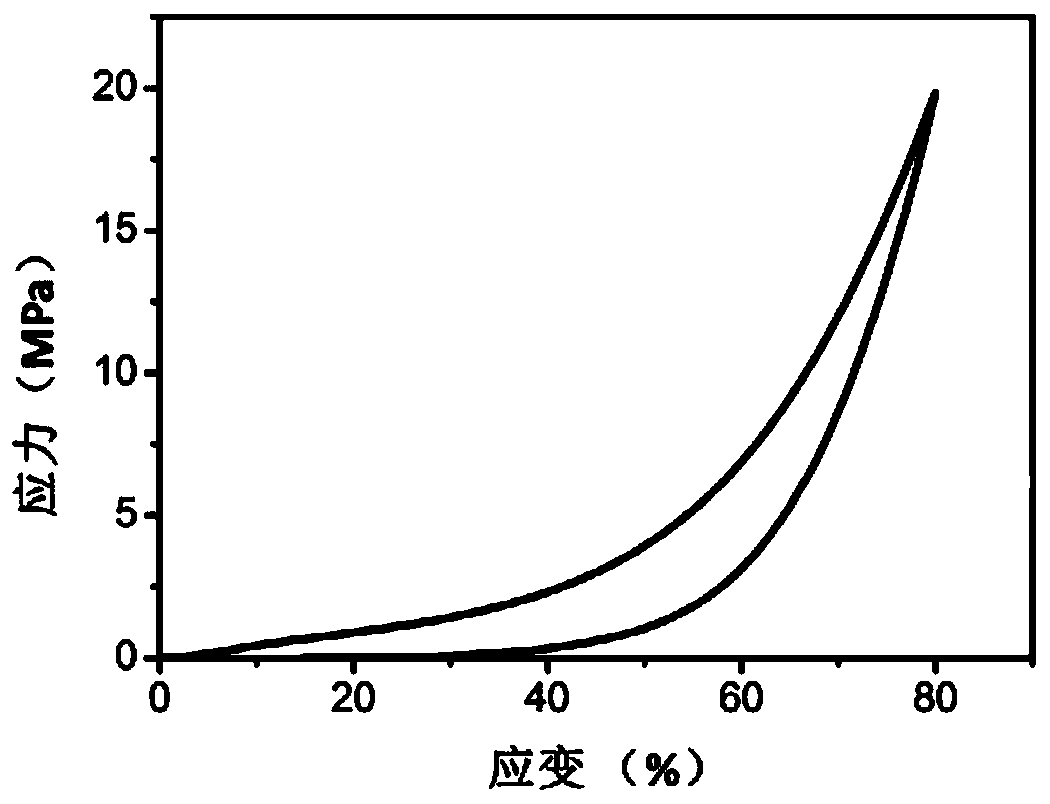

An aerogel, double-crosslinking technology, applied in the field of preparation of elastic double-crosslinking aerogel, can solve the problems of unfavorable practical application, increase of density and thermal conductivity, decrease of specific surface area and porosity of aerogel, etc. Achieve excellent transparency, good elasticity and hydrophobicity, avoiding the effect of supercritical drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: A certain amount of vinylmethyldimethoxysilane is placed in a container, di-tert-butyl peroxide is added thereto, and then the surface of the liquid is covered with argon. After sealing the container, heat it at 130°C for 48 hours, and obtain a transparent viscous liquid after cooling down. Wherein, the molar ratio of vinylmethyldimethoxysilane to di-tert-butyl peroxide is 1:0.01.

[0035] Add n-butanol, water, and tetraethylammonium hydroxide to the viscous liquid in sequence. Wherein, the molar ratio of vinylmethyldimethoxysilane, n-butanol, water, and tetraethylammonium hydroxide is 1:4:2:0.045. The resulting sol was stirred for 4 minutes, transferred to a container and sealed, and then placed in an oven at 95° C. to gel and aged for 4 days. The resulting gel was replaced with ethanol four times for 12 hours each. The aerogel was obtained by volatilizing the gel under normal pressure at a temperature of 50° C. for 48 hours.

[0036] The sample obtained...

Embodiment 2

[0037] Example 2: A certain amount of vinylmethyldiethoxysilane was placed in a container, azobisisobutyronitrile was added thereto, and then the surface of the liquid was covered with nitrogen. After the container was sealed, it was heated at 140°C for 48 hours, and a transparent viscous liquid was obtained after cooling down. Wherein, the molar ratio of vinylmethyldiethoxysilane to azobisisobutyronitrile is 1:0.2.

[0038] Add benzyl alcohol, water, and ammonia water to the viscous liquid in sequence. Wherein, the molar ratio of vinylmethyldiethoxysilane, benzyl alcohol, water and ammonia water is 1:5:2:0.03. The resulting sol was stirred for 1 min, transferred to a container and sealed, then gelled and aged at room temperature for 4 days. The resulting gel was replaced 3 times with isopropanol for 6 hours each. The gel is placed in a carbon dioxide supercritical drying device for supercritical drying to obtain an aerogel.

[0039] The obtained sample has a density of 0....

Embodiment 3

[0040] Example 3: A certain amount of allylmethyldimethoxysilane was placed in a container, di-tert-butyl peroxide was added thereto, and then the liquid surface was covered with nitrogen. After the container was sealed, it was heated at 120°C for 72 hours, and a transparent viscous liquid was obtained after cooling down. Wherein, the molar ratio of allylmethyldimethoxysilane to di-tert-butyl peroxide is 1:0.2.

[0041] Add isopropanol, water, and tetramethylammonium hydroxide to the viscous liquid in sequence. Wherein, the molar ratio of allylmethyldimethoxysilane, isopropanol, water, and tetramethylammonium hydroxide is 1:5:1.5:0.06. The obtained sol was stirred for 10 minutes, transferred to a container and sealed, and then placed in an oven at 80° C. to gel and age for 2 days. The resulting gel was replaced 4 times with isopropanol for 12 hours each. The gel is placed in a carbon dioxide supercritical drying device for supercritical drying to obtain an aerogel.

[0042...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com