Efficient waterborne nano silicone rubber sealing waterproof agent

A technology of nano-silicone rubber and waterproofing agent, applied in the field of waterproofing agent, can solve the problems of incomplete waterproofing, impermeability damage, and failure to meet the requirements of buildings, etc., to improve heat resistance and cold resistance, and strong penetration , Improve the effect of stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

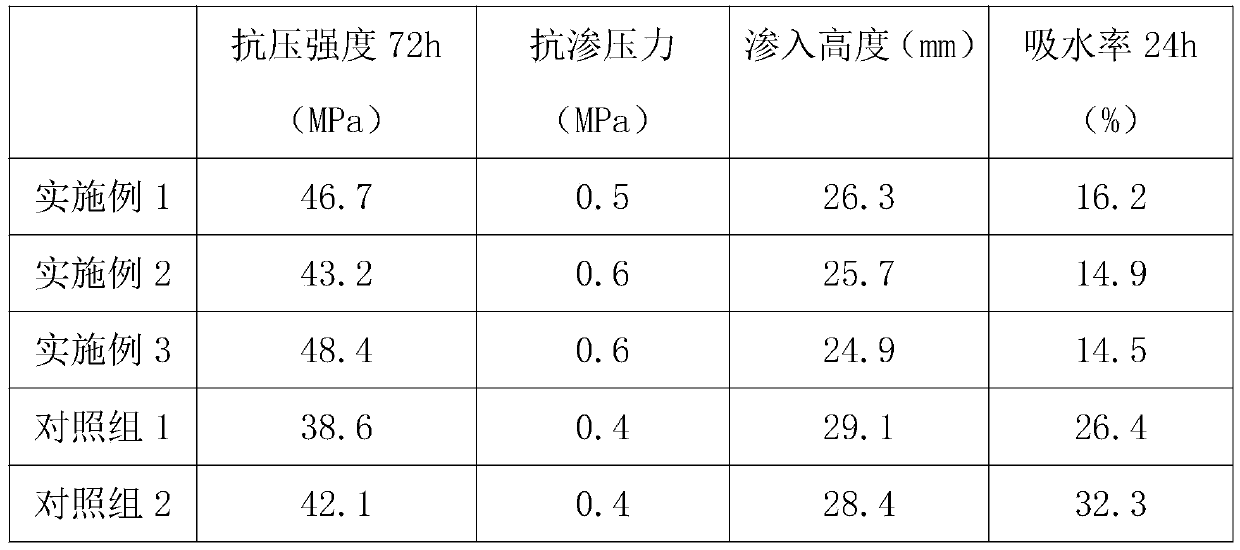

Examples

Embodiment 1

[0023] A high-efficiency water-based nano-silicone rubber sealing and waterproofing agent is made of the following components by weight: 12 parts of nano-calcium carbonate powder, 20 parts of nano-silica dispersion liquid, 21 parts of lithium silicate solution, 14 parts of polyphenylene particles, alkane 6 parts of sodium phenyl sulfonate, 16 parts of fly ash, 13 parts of calcium stearate, 9 parts of sodium methyl silicate, 2 parts of fluorocarbon surfactant, 3 parts of triethanolamine, 1 part of defoamer and 11 parts of ionized water.

[0024] The fineness of the fly ash is 80 mesh, and the fineness of the polyphenylene particles is 60 mesh.

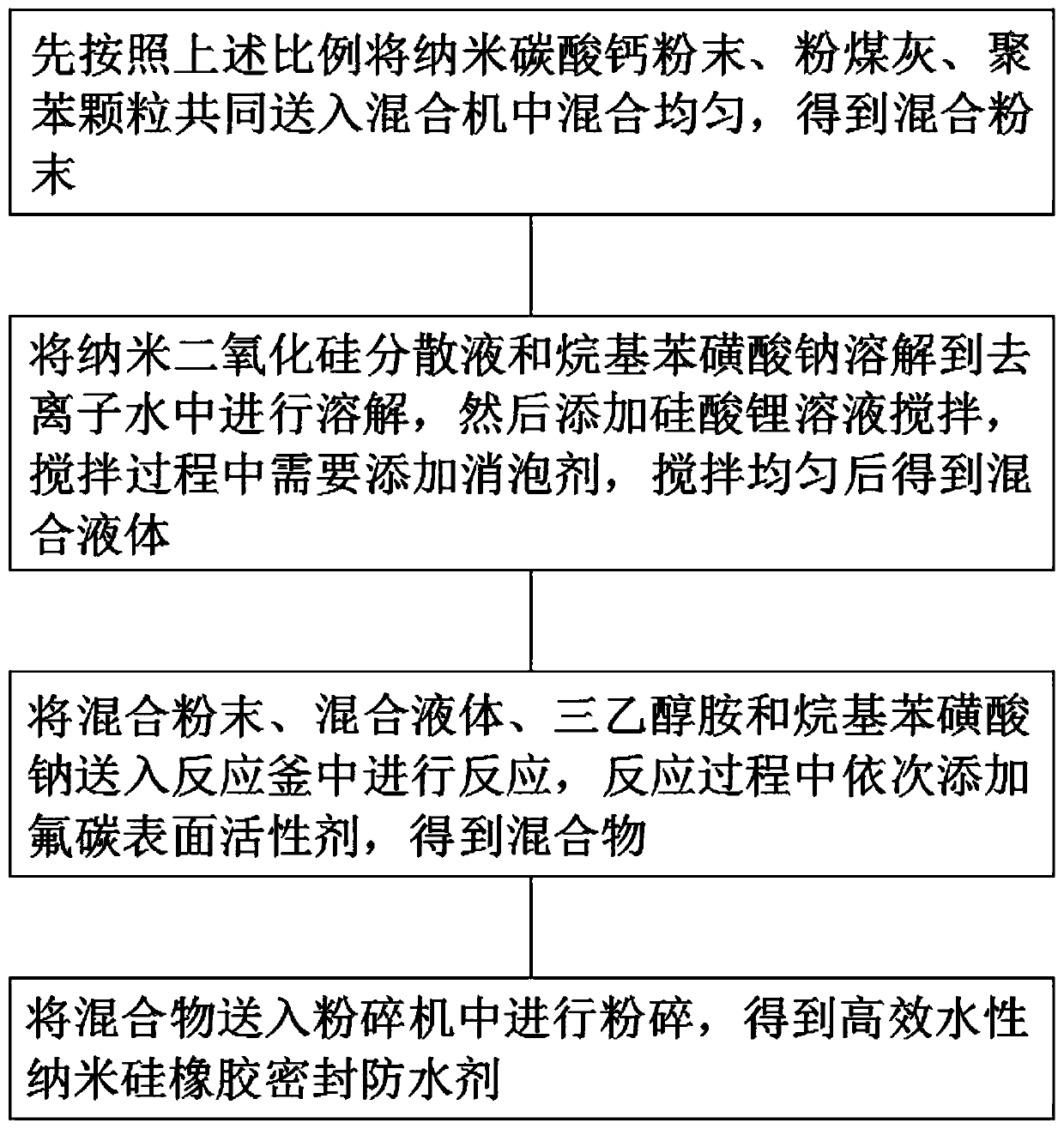

[0025] The preparation steps of high-efficiency water-based nano-silicone rubber sealing and waterproofing agent are as follows:

[0026] ①. First, according to the above ratio, the nano-calcium carbonate powder, fly ash, and polyphenylene particles are jointly sent into the mixer and mixed evenly to obtain a mixed powder. The mixer ad...

Embodiment 2

[0031] A high-efficiency water-based nano-silicone rubber sealing and waterproofing agent, made of the following components by weight: 13 parts of nano-calcium carbonate powder, 21 parts of nano-silica dispersion, 25 parts of lithium silicate solution, 14 parts of polyphenylene particles, 6 parts of sodium alkylbenzene sulfonate, 18 parts of fly ash, 13 parts of calcium stearate, 8 parts of sodium methyl silicate, 2 parts of fluorocarbon surfactant, 4 parts of triethanolamine and 2 parts of defoamer and 10 parts of deionized water.

[0032] The fineness of the fly ash is 80 mesh, and the fineness of the polyphenylene particles is 60 mesh.

[0033] The preparation steps of high-efficiency water-based nano-silicone rubber sealing and waterproofing agent are as follows:

[0034] ①. First, according to the above ratio, the nano-calcium carbonate powder, fly ash, and polyphenylene particles are jointly sent into the mixer and mixed evenly to obtain a mixed powder. The mixer adopts...

Embodiment 3

[0039] A high-efficiency water-based nano-silicone rubber sealing and waterproofing agent is made of the following components by weight: 12 parts of nano-calcium carbonate powder, 20 parts of nano-silica dispersion liquid, 21 parts of lithium silicate solution, 14 parts of polyphenylene particles, alkane 6 parts of sodium phenyl sulfonate, 16 parts of fly ash, 14 parts of calcium stearate, 9 parts of sodium methyl silicate, 1 part of fluorocarbon surfactant, 3 parts of triethanolamine, 1 part of defoamer and 11 parts of ionized water.

[0040] The fineness of the fly ash is 80 mesh, and the fineness of the polyphenylene particles is 60 mesh.

[0041] The preparation steps of high-efficiency water-based nano-silicone rubber sealing and waterproofing agent are as follows:

[0042]①. First, according to the above ratio, the nano-calcium carbonate powder, fly ash, and polyphenylene particles are jointly sent into the mixer and mixed evenly to obtain a mixed powder. The mixer adop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com