Water-based non-asphalt-based non-curing waterproof coating and preparation method thereof

A non-asphalt-based, waterproof coating technology, applied in rosin coatings, chloroprene homopolymer coatings, coatings, etc., can solve problems such as complex production and construction techniques, environment, personnel hazards, and expensive equipment, and achieve construction High efficiency, long-term viscous state, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A water-based non-asphalt-based non-curing waterproof coating and its preparation method are as follows:

[0044] First, 10 parts of water, 4 parts of polycarboxylate dispersant, 50 parts of pure acrylic emulsion, 150 parts of terpene resin, 30 parts of in-situ modified acrylic emulsion, and 5 parts of nano-montmorillonite silane modified by acrylic monomer During the stirring process, add the agent in turn to the stirring tank and stir evenly, then add 30 parts of calcium carbonate and 100 parts of talcum powder to disperse evenly, continue to add 30 parts of dibutyl phthalate, 2 parts of cyclic Oxyethane polyurethane thickener, 0.5 part of condensed heterocyclic antifungal agent, 1 part of isothiazolin-3-one preservative, and finally 200 parts of esterified rosin emulsion, stirred evenly, and then discharged and packaged to obtain the finished product.

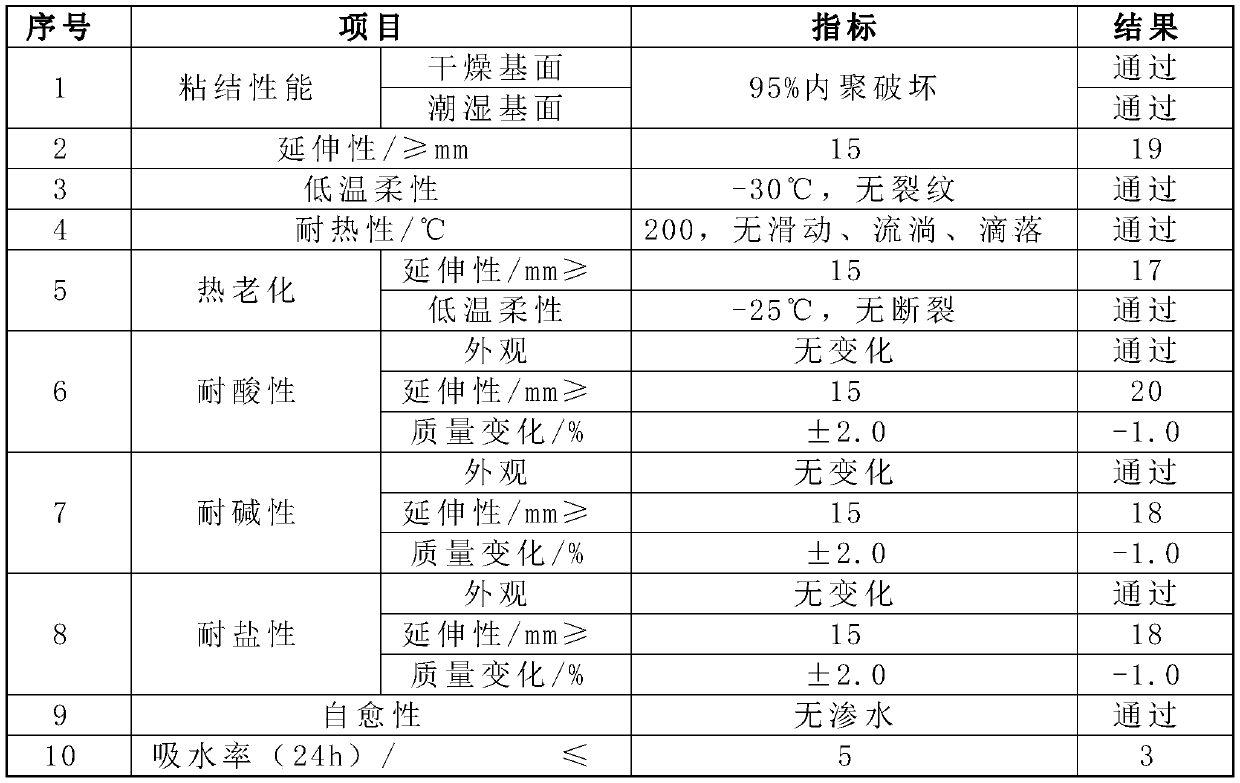

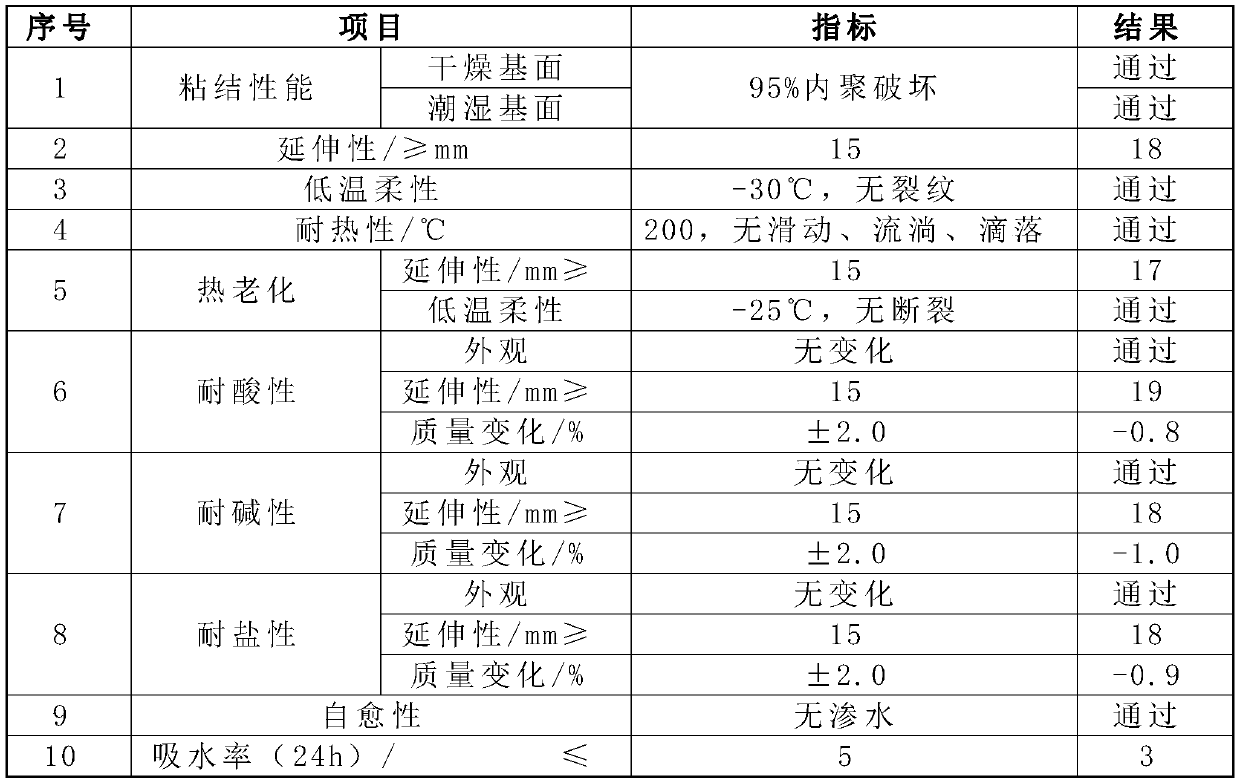

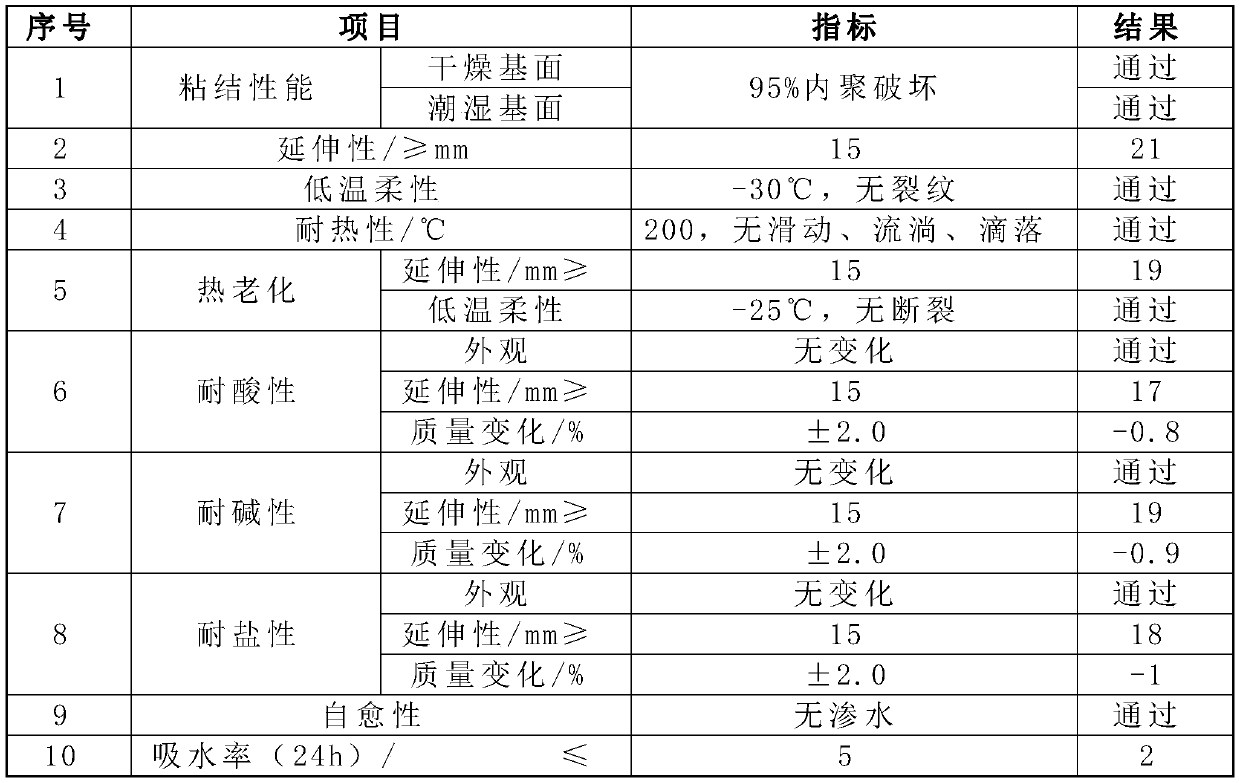

[0045] Due to the originality and novelty of the present invention, there are no relevant national, industry, local...

Embodiment 2

[0049] A water-based non-asphalt-based non-curing waterproof coating and its preparation method are as follows:

[0050] First, 120 parts of water, 6 parts of polymethacrylic acid derivative dispersant, 80 parts of pure acrylic emulsion, 10 parts of ethylene vinyl acetate copolymer emulsion, 150 parts of fumaric acid modified rosin emulsion, 40 parts of neoprene rubber emulsion, 6 parts The nano-montmorillonite silane coupling agent modified by acrylic acid monomer is added to the stirring tank in turn during the stirring process and stirred evenly, then 70 parts of kaolin and 100 parts of barium sulfate are added in turn to disperse evenly, and 100 parts of barium sulfate are added in turn during the stirring process Bis(2-ethylhexyl) phthalate, 1 part of hydrophobic modified acrylic thickener, 0.7 part of fused heterocyclic antifungal agent, 1.5 parts of isothiazolin-3-one preservative, and finally added 210 parts of esterified rosin emulsions were stirred evenly and packed ...

Embodiment 3

[0055] A water-based non-asphalt-based non-curing waterproof coating and its preparation method are as follows:

[0056] First, 150 parts of water, 5 parts of maleic acid dry copolymer dispersant, 30 parts of pure acrylic emulsion, 30 parts of styrene-butadiene rubber emulsion, 65 parts of butyl rubber emulsion, and 2 parts of acrylic acid monomer modified nano-montmorillonite Soil silane coupling agent, during the stirring process, add it into the stirring tank in turn and stir evenly, then add 30 parts of wollastonite powder and 80 parts of mica powder in turn to disperse evenly, continue to add 35 parts of diisodecyl phthalate in turn during the stirring process ester, 12 parts of hydrophobic modified acrylic thickener, 0.8 part of condensed heterocyclic antifungal agent, 1 part of isothiazolin-3-one preservative, and finally add 290 parts of esterified rosin emulsion, stir well and discharge Packaging is the finished product.

[0057] The performance test results are show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com