Double signal amplified zearalenone impedance sensor based on nano-Co3O4 mimic enzyme catalysis action

A technology of zearalenone and simulating enzymes, which can be applied in the fields of instruments, scientific instruments, electrochemical variables of materials, etc., and can solve the problems of variability and poor stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

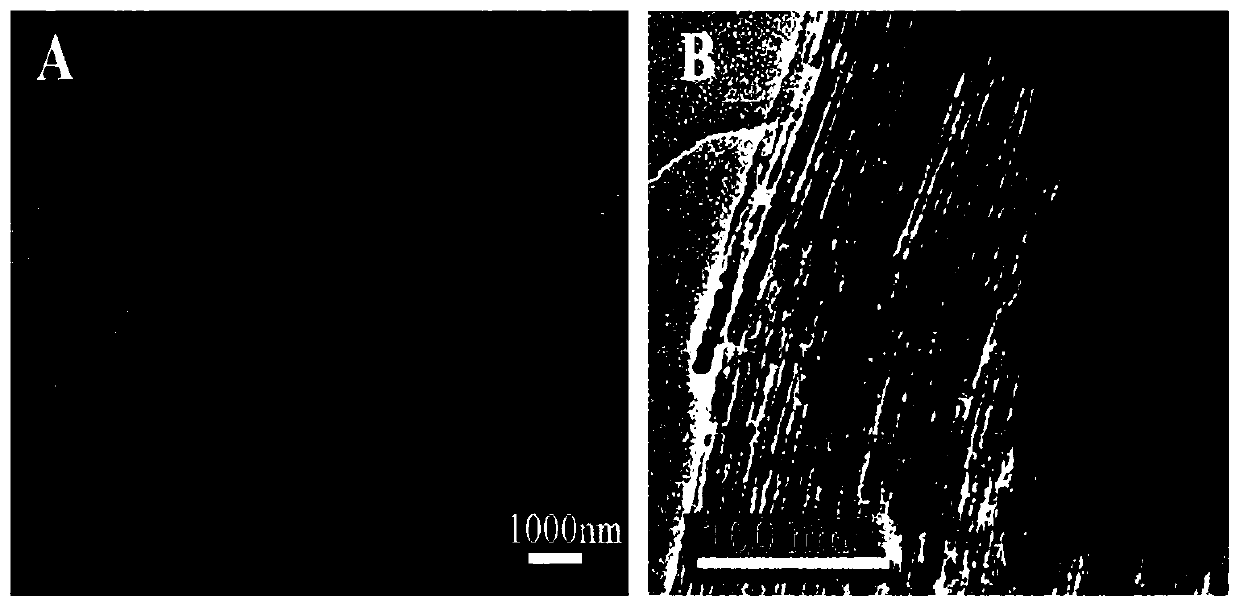

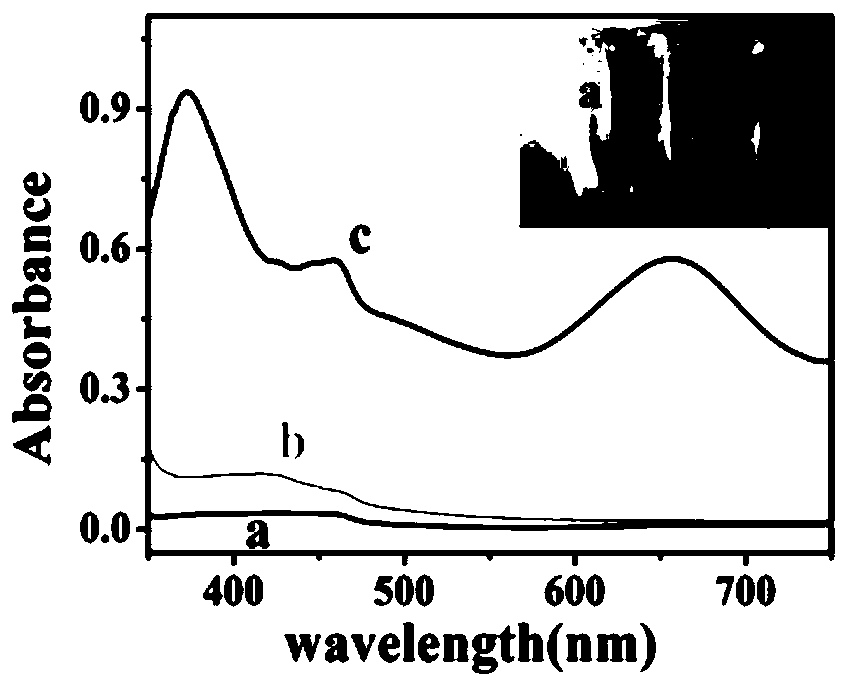

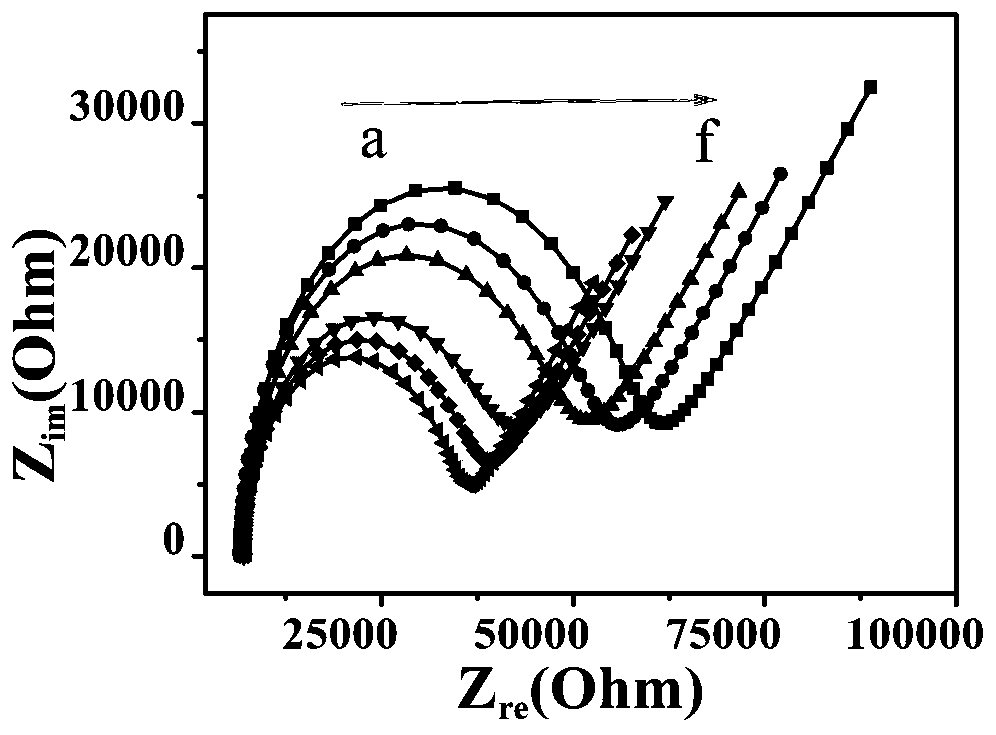

[0035] 1. One based on nano-Co 3 O 4 The method for preparing a double-amplified zearalenone impedance sensor that simulates enzyme catalysis is characterized in that the preparation method mainly includes the following steps:

[0036] (1) The glassy carbon electrode is mechanically polished with 50nm and 30nm alumina powder on the moist suede, and then rinsed with double distilled water and absolute ethanol until the surface of the electrode is clean and bright.

[0037] (2) Pipette 5 μL of hyaluronic acid functionalized TiO with a concentration of 3 mg / L 2 Mesogenic solution (TiO 2 @Hya) Add dropwise to the surface of the clean glassy carbon electrode, dry it in the infrared light box, take it out, and cool to room temperature to prepare TiO 2 @Hya modified glassy carbon electrode;

[0038] (3) Add dropwise 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride (EDC) and N-hydroxysulfosuccinimide sodium salt with a volume ratio of 2:1 ( The mixed solution of NHS) activates the c...

Embodiment 2

[0045] The hyaluronic acid functionalized TiO used in Example 1 above 2 The mesogen solution is prepared by the following method:

[0046] 1) 0.5g of sodium dodecylbenzene sulfonate (SDBS) dissolved in 25 mL of 2.2 mol / L HNO 3 In the solution, continue to stir and shake for tens of minutes, then add 500 µL of isopropyl titanate (TIP), and then continue to shake the above mixture at 48 °C for 24 hours, and then rinse the mixture with deionized water and absolute ethanol. Second, dry overnight at 60°C. After drying, it was calcined at 400 °C for 60 min to fully remove residual organic matter and obtain the final product. Disperse the resulting product in deionized water and store it in a refrigerator at 4°C for later use.

[0047] 2) TiO functionalized with hyaluronic acid 2 The mesogen solution was prepared by the following method: 500 μL hyaluronic acid solution with a concentration of 5 mg / mL and 500 μL TiO with a concentration of 5 mg / mL 2 The mesogen was mixed and shaken for 1 ...

Embodiment 3

[0049] K-Co used in Example 1 above 3 O 4 Prepared by the following method:

[0050] 1) 6g of the addition polymer of polypropylene glycol and ethylene oxide is dissolved in a mixed solution of 217g of deionized water and 11.8g of 35% hydrochloric acid. At 35°C, 6g of butanol is added to the above solution, and stirring is continued for 1h Then, at 35°C, 12.9 g of polytetramethoxysilane was added, and then stirring was continued for 24 hours. Subsequently, the above mixture was heated at 100°C and kept for 24h, and the solid product obtained after the hydrothermal treatment was filtered and dried at 100°C. The obtained product was extracted in a mixture of ethanol and hydrochloric acid, calcined at 550°C, and cooled to prepare a KIT-6 template.

[0051] 2) 0.776 g of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) Dissolve the precursor solution in 5 mL of anhydrous ethanol solution, continue to stir for 30 minutes, add 0.2g of the KIT-6 template prepared in step (1), and continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com