Metal atom-doped porous carbon nano composite material as well as a preparation method and application thereof

A technology of nano-composite materials and metal atoms, which is applied in the field of metal atom-doped porous carbon nano-composite materials and its preparation, can solve the problems of increased electrolyte viscosity, low Coulomb efficiency, decreased electrical conductivity, etc., and achieves improved cycle stability. , the effect of relieving volume expansion and inhibiting the shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

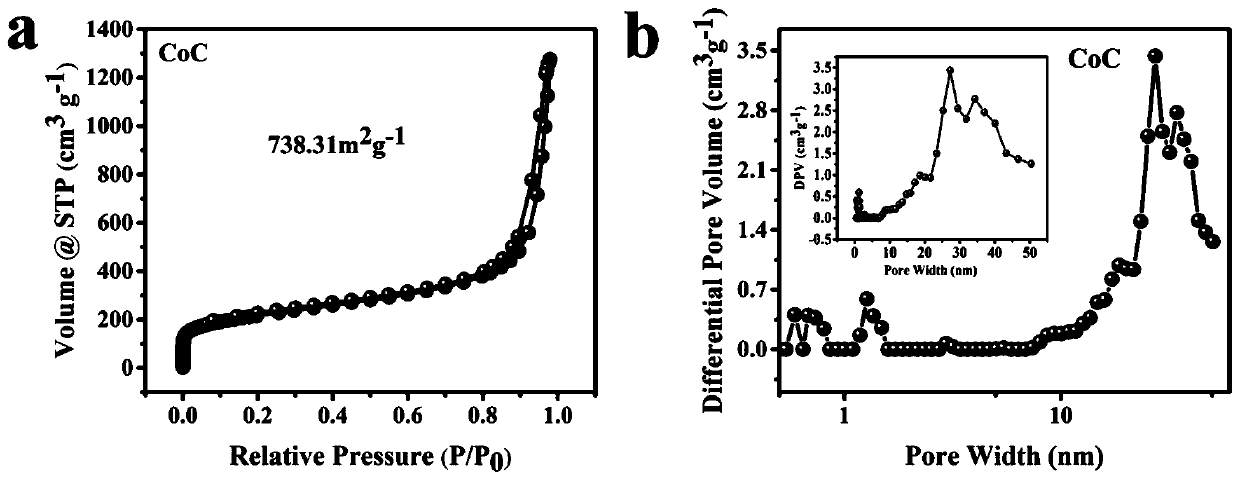

[0042] Preparation of a Metal Atom-doped Porous Carbon Nanocomposite

[0043] (1) Dissolving the metal salt (cobalt chloride hexahydrate) and the carbon source (polyacrylonitrile) in the solvent (dimethyl sulfoxide) at a mass ratio of 1:5:50, and mixing to form a precursor solution;

[0044](2) Add a template (fumed silica) to the precursor solution obtained in step (1) at a mass ratio of 1:10 and react at 30° C. for 24 hours to obtain solution I;

[0045] (3) The solution I obtained in step (2) was dropped into liquid nitrogen for rapid cooling, and then immediately transferred to a freeze dryer for freeze-drying for 24 hours to obtain solid I;

[0046] (4) Pre-oxidize the solid I obtained in step (3), specifically heating up to 280°C at a rate of 1°C / min and then keeping it warm for 2 hours to obtain solid II;

[0047] (5) Carbonize the solid II obtained in step (4) under a protective atmosphere, specifically heating up to 900°C at a rate of 5°C / min and then keeping it warm...

Embodiment 2

[0050] Preparation of a Metal Atom-doped Porous Carbon Nanocomposite

[0051] (1) Dissolve metal salt (cobalt chloride hexahydrate) and carbon source (chitosan) in solvent (acetone) according to the mass ratio of 1:10:70, and form a precursor solution after mixing;

[0052] (2) Add templates (polypropylene pellets) to the precursor solution obtained in step (1) at a mass ratio of 1:1 and react at 45°C for 30 hours to obtain solution I;

[0053] (3) The solution I obtained in step (2) was frozen at -80°C for 8 hours, and then immediately transferred to a freeze dryer for freeze-drying for 12 hours to obtain solid I;

[0054] (4) Pre-oxidize the solid I obtained in step (3), specifically heating up to 400°C at a rate of 10°C / min and then keeping it warm for 1h to obtain solid II;

[0055] (5) Carbonize the solid II obtained in step (4) under a protective atmosphere, specifically heating up to 1500°C at a rate of 10°C / min and then keeping it warm for 5 hours to obtain solid III;...

Embodiment 3

[0058] Preparation of a Metal Atom-doped Porous Carbon Nanocomposite

[0059] (1) Dissolving metal salt (cobalt chloride hexahydrate) and carbon source (polyvinyl alcohol) in solvent (methyl acetate) in a mass ratio of 1:2:10, and mixing to form a precursor solution;

[0060] (2) Add template (sodium chloride) to the precursor solution obtained in step (1) at a mass ratio of 1:30 and react at 95° C. for 24 hours to obtain solution I;

[0061] (3) The solution I obtained in step (2) was dropped into liquid nitrogen for rapid cooling, and then immediately transferred to a freeze dryer for freeze-drying for 36 hours to obtain a solid I;

[0062] (4) Pre-oxidizing the solid I obtained in step (3), specifically heating up to 320°C at a rate of 5°C / min and then keeping it warm for 12 hours to obtain solid II;

[0063] (5) Carbonize the solid II obtained in step (4) under a protective atmosphere, specifically heating up to 1200°C at a rate of 8°C / min and then keeping it warm for 18 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com