Yellow corn stalk silage feed preparation method

A corn stalk and feed technology, applied in animal feed, animal feed, application and other directions, can solve the problems of fermentation failure, incomplete fermentation, insufficient nutritional components, etc., and achieve comprehensive nutritional components, high nutritional components, and aerobic stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

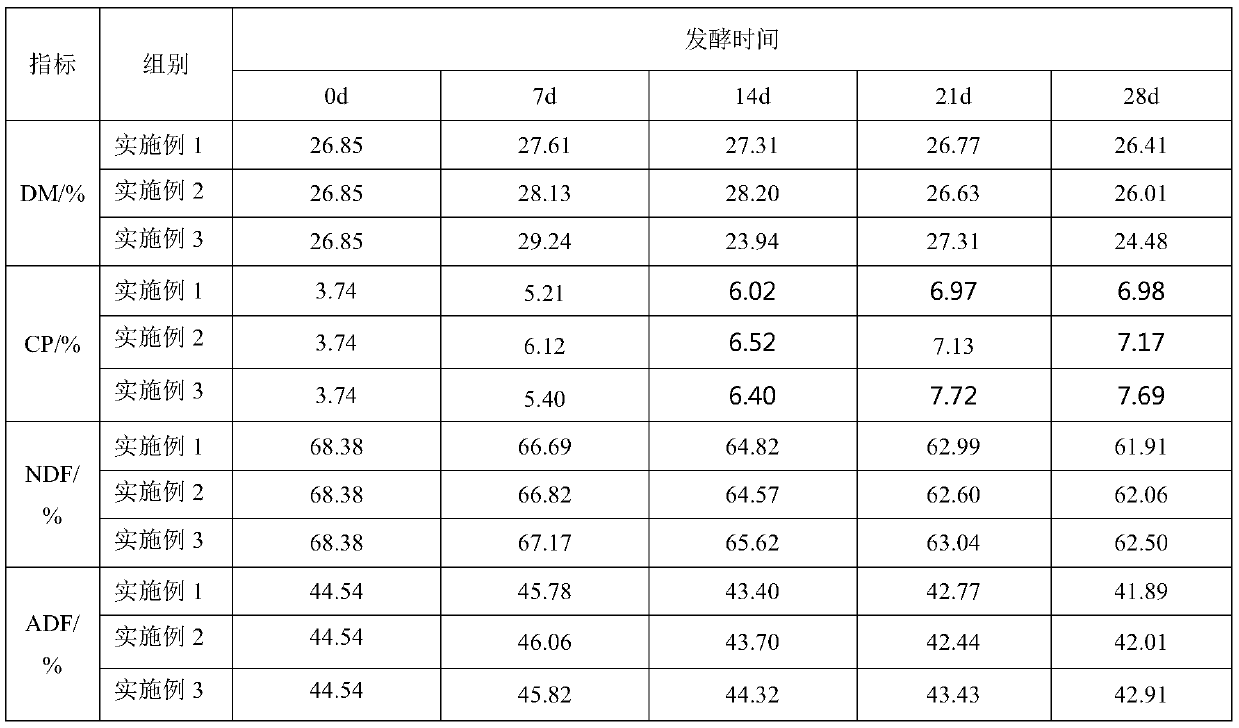

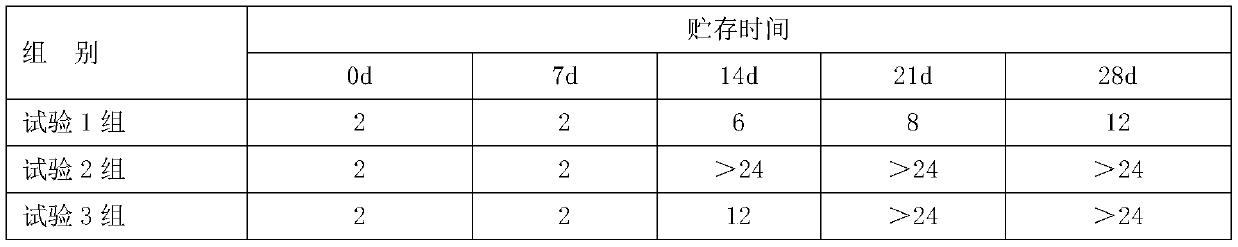

[0016] A method for preparing corn stalk yellow storage feed, characterized in that 100 parts by mass of corn stalk are fermented and placed in a universal grinder, crushed through a 10-20 mesh sieve, then placed in a suitable container, and pressed The solid-liquid ratio is 1:5, add 0.2mol / L sodium hydroxide solution, heat up to 60°C for 2 hours, then add 0.1mol / L hydrochloric acid solution to adjust the pH of the solution to 6.80, filter, take the filter cake, and dry until Constant weight, as the fermentation substrate, then put the fermentation substrate in a closed fermenter, add 200 parts by mass of purified water, then add 0.20 parts by mass of Schizophyllum, set the fermentation temperature to 24°C, and ferment in a closed container for 7 days, Add 0.20 mass parts of lactic acid bacteria and saccharomyces complex bacteria, continue to ferment for 28 days, take out, filter, and collect filter cake to obtain.

[0017] The degradation efficiencies of cellulose, hemicellul...

Embodiment 2

[0019] A method for preparing corn stalk yellow storage feed, characterized in that 100 parts by mass of corn stalk are fermented and placed in a universal grinder, crushed through a 10-20 mesh sieve, then placed in a suitable container, and pressed The solid-liquid ratio is 1:8, add 0.5mol / L sodium hydroxide solution, heat up to 80°C for 5 hours, then add 0.1mol / L hydrochloric acid solution to adjust the pH of the solution to 7.20, filter, take the filter cake, and dry until Constant weight, as the fermentation substrate, then put the fermentation substrate in a closed fermenter, add 250 parts by mass of purified water, then add 0.25 parts by mass of Schizophyllum, set the fermentation temperature to 28°C, and ferment in a closed container for 9 days, Add 0.25 parts by mass of a composite bacterium composed of lactic acid bacteria and yeast, continue to ferment for 28 days, take it out, filter, and collect the filter cake to obtain the product.

[0020] The degradation effici...

Embodiment 3

[0022] A method for preparing corn stalk yellow storage feed, characterized in that 100 parts by mass of corn stalk are fermented and placed in a universal grinder, crushed through a 10-20 mesh sieve, then placed in a suitable container, and pressed The solid-liquid ratio is 1:6, add 0.3mol / L sodium hydroxide solution, heat up to 70°C for 3 hours, then add 0.1mol / L hydrochloric acid solution to adjust the pH of the solution to 7.00, filter, take the filter cake, and dry until Constant weight, as the fermentation substrate, then put the fermentation substrate in a closed fermenter, add 230 parts by mass of purified water, then add 0.22 parts by mass of Schizophyllum, set the fermentation temperature to 26°C, and ferment in a closed container for 8 days, Add 0.23 mass parts of lactic acid bacteria and saccharomyces complex bacteria, continue to ferment for 28 days, take out, filter, and collect filter cake to obtain.

[0023] The degradation efficiency of cellulose, hemicellulos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com