Milk flavored cordyceps militaris and fish noodles and production method

A production method and a technology of milk flavor, which is applied in the field of food processing, can solve the problems of single type and taste, poor cooking resistance, and unremarkable nutritional and health care effects, so as to improve cooking performance and taste, solve time-consuming problems, and enrich nutrition and health care The effect of efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

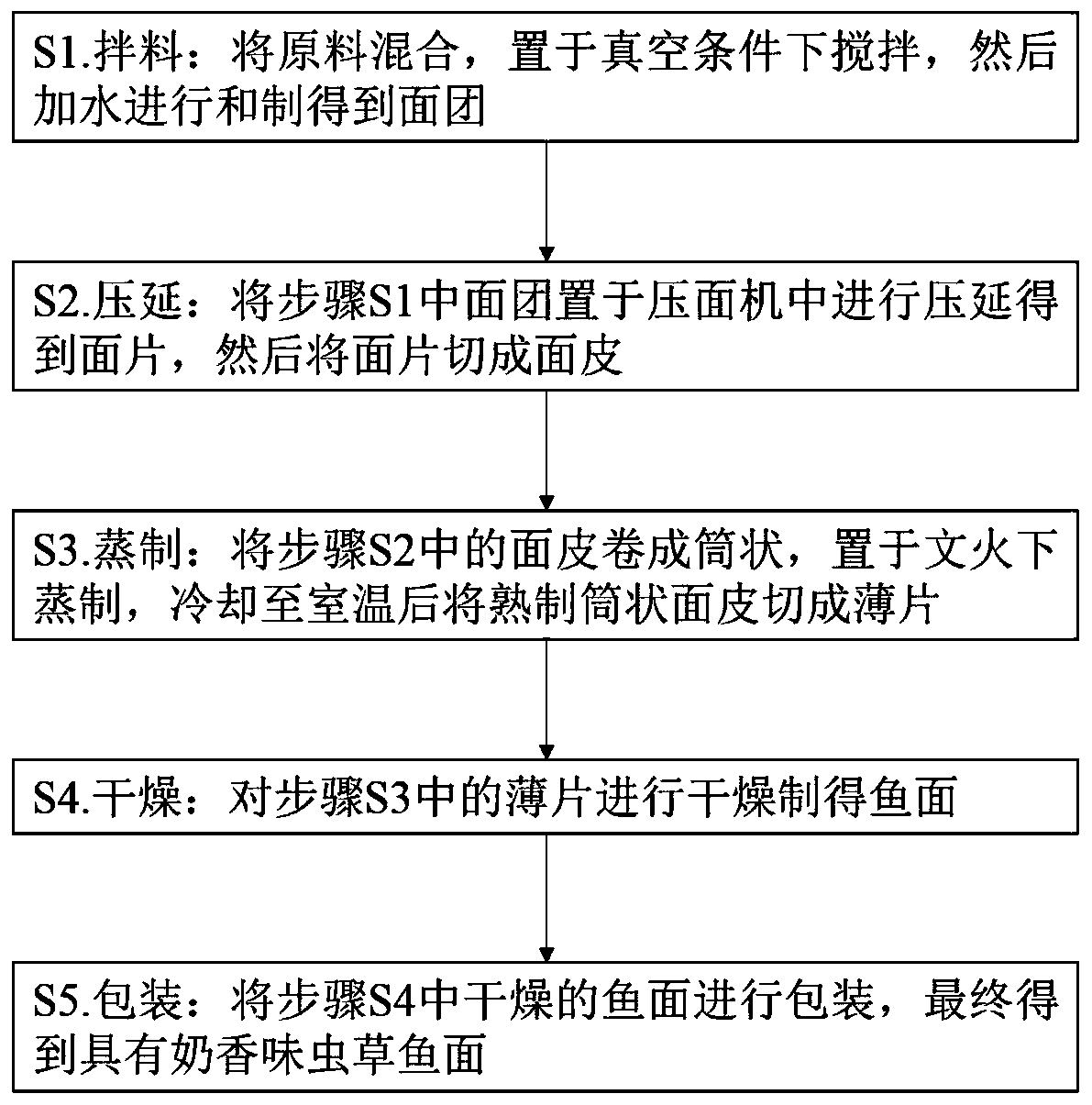

Method used

Image

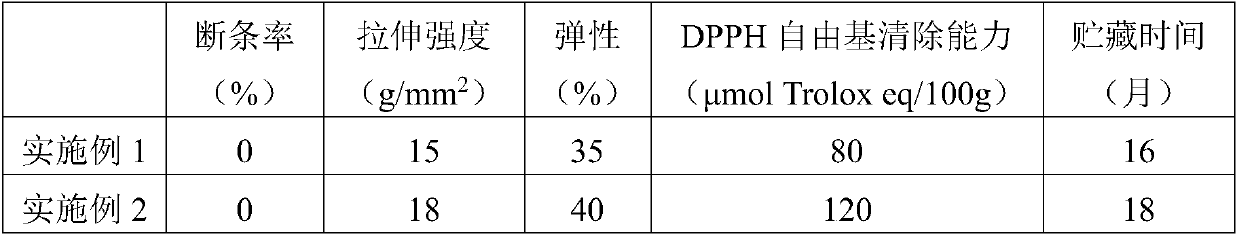

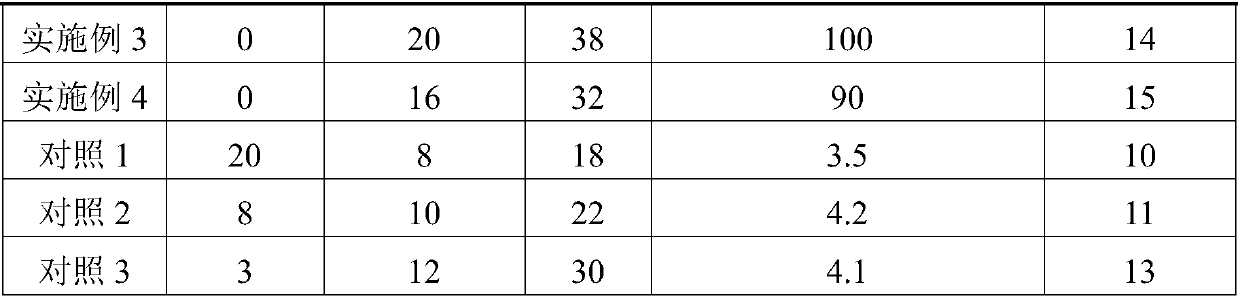

Examples

preparation example Construction

[0038] The preparation process of the starch mixture in step S1 is as follows: commercially available sweet potato starch and commercially available lotus root starch are mixed in a weight ratio of 10:1-3, and then prepared into starch milk with a concentration of 15-30% (w / v). Take the culture solution of Lactobacillus plantarum and Lactobacillus pentosus activated and cultivated to the late logarithmic phase of the bacteria, the volume ratio of the two is 5:1-3, the total volume of the culture solution taken is 25-40mL, and the culture solution Centrifuge the liquid at 5000r / min for 15min, collect the precipitate obtained by centrifugation, inoculate the precipitate into 100-300g of the starch milk, mix well, put it in a sealed condition of 30-50°C and ferment for 8-20h, and the fermentation is completed Afterwards, the starch milk was freeze-dried, crushed and passed through a 100-mesh sieve to obtain a starch mixture.

[0039] In step S1, the production process of the Cord...

Embodiment 1

[0048] (1) First select one or more of fresh silver carp, grass carp, bighead carp and snakeheaded carp as raw materials, after peeling, removing thorns, removing internal organs, and cleaning, the fish meat is obtained, and the fish meat is mixed with water at a weight ratio of 1:0.1 After several chopping and mixing, the surimi was pulverized by a colloid mill. After the surimi was mixed with edible salt at a weight ratio of 20:1, the surimi gel was finally obtained at 120r / min for 6 minutes, and 150kg of surimi was obtained. The gel is ready for use.

[0049] According to the weight ratio of 10:1, the commercially available sweet potato starch and lotus root powder were mixed and configured into starch milk with a concentration of 20% (w / v); Lactobacillus plantarum and Lactobacillus pentosus culture solution, the total volume of the culture solution is 30mL; the culture solution is centrifuged at 5000r / min for 15min, the centrifuged precipitate is collected, and the precipi...

Embodiment 2

[0058] (1) First select one or more of fresh silver carp, grass carp, bighead carp and snakeheaded carp as raw materials, after peeling, removing thorns, removing internal organs, and cleaning, the fish meat is obtained, and the fish meat is mixed with water at a weight ratio of 1:0.15 After repeated chopping and mixing, the surimi was pulverized by a colloid mill. After the surimi and edible salt were mixed at a weight ratio of 20:1.5, the surimi gel was obtained by stirring at 150 r / min for 10 minutes. Take 160 kg of surimi gel. Glue spare.

[0059] Take commercially available sweet potato starch and lotus root starch at a weight ratio of 10:1.5, mix them and configure them into starch milk with a concentration of 15% (w / v); then take them respectively at a volume ratio of 5:2.5 and cultivate them until the late logarithmic growth phase Lactobacillus plantarum and Lactobacillus pentosus culture solution, the total volume of the culture solution is 35mL; the culture solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com