Sulfur-doped MXene negative electrode material as well as preparation method and application thereof

A negative electrode material, sulfur doping technology, used in battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as unsatisfactory performance, achieve improved rate performance and cycle stability, good electrical conductivity, improved The effect of specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

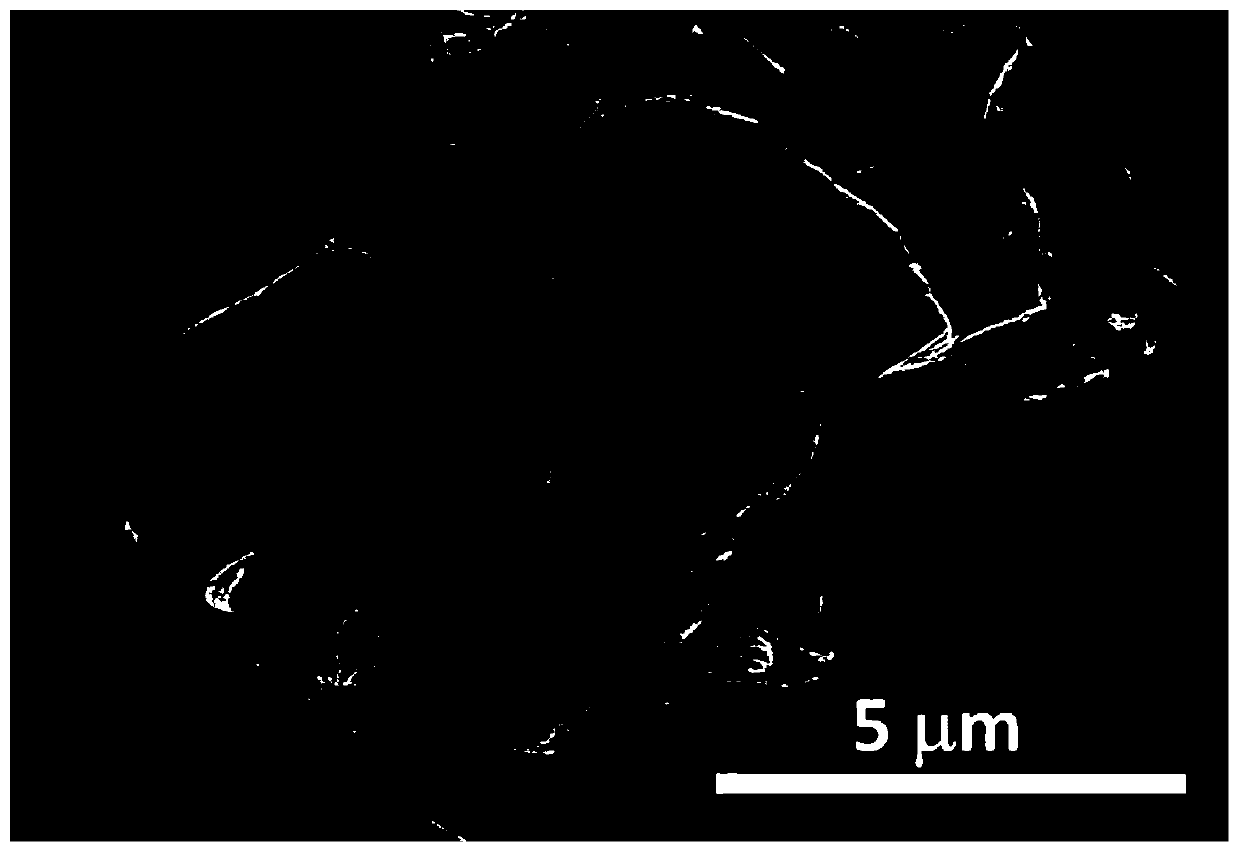

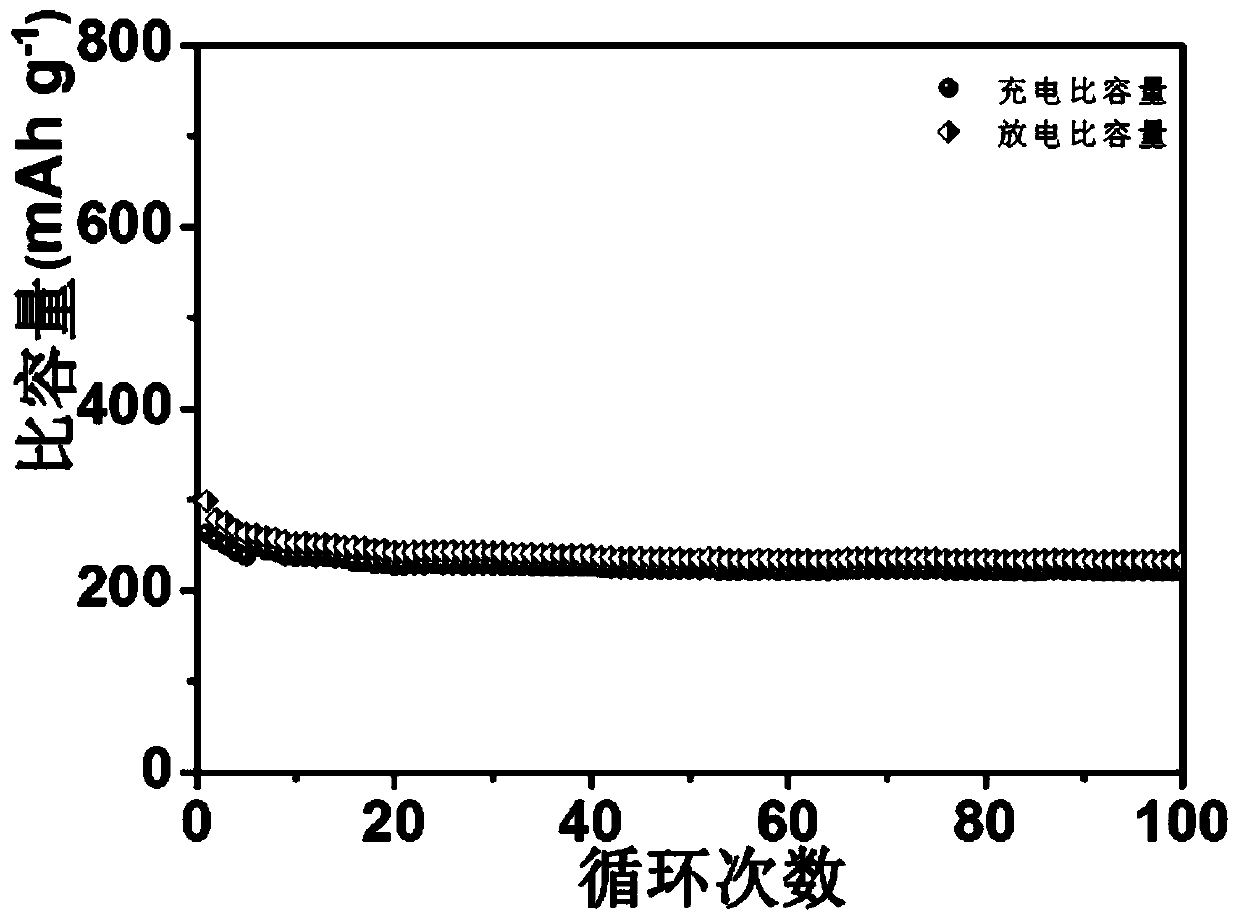

[0032] A preparation method of sulfur-doped MXene negative electrode material includes the following steps:

[0033] (1) Weigh 0.2g of V 2 CT x Place 4g of 2-phenylethanethiol on both ends of the quartz boat, and place the end with 2-phenylethylthiol on the upstream of the tube furnace;

[0034] (2) Under the protective atmosphere of high-purity argon (purity ≥99.8%) with a gas flow rate of 160ml / min, the temperature is increased from room temperature 20°C at 1.5°C / min to 170°C, kept for 2h, and then cooled at 0.5°C / min To 100°C, keep it at 100°C for 2h, then lower to room temperature, wash the sample with deionized water after cooling, and vacuum dry to obtain the final sample.

[0035] (3) Preparation of the negative electrode of potassium ion battery: mix the sulfur-doped MXene obtained in step (2) with polyvinylidene fluoride binder and carbon black in a mass ratio of 8:1:1, and add an appropriate amount of N- Methylpyrrolidone is uniformly stirred to form a slurry and coated on...

Embodiment 2

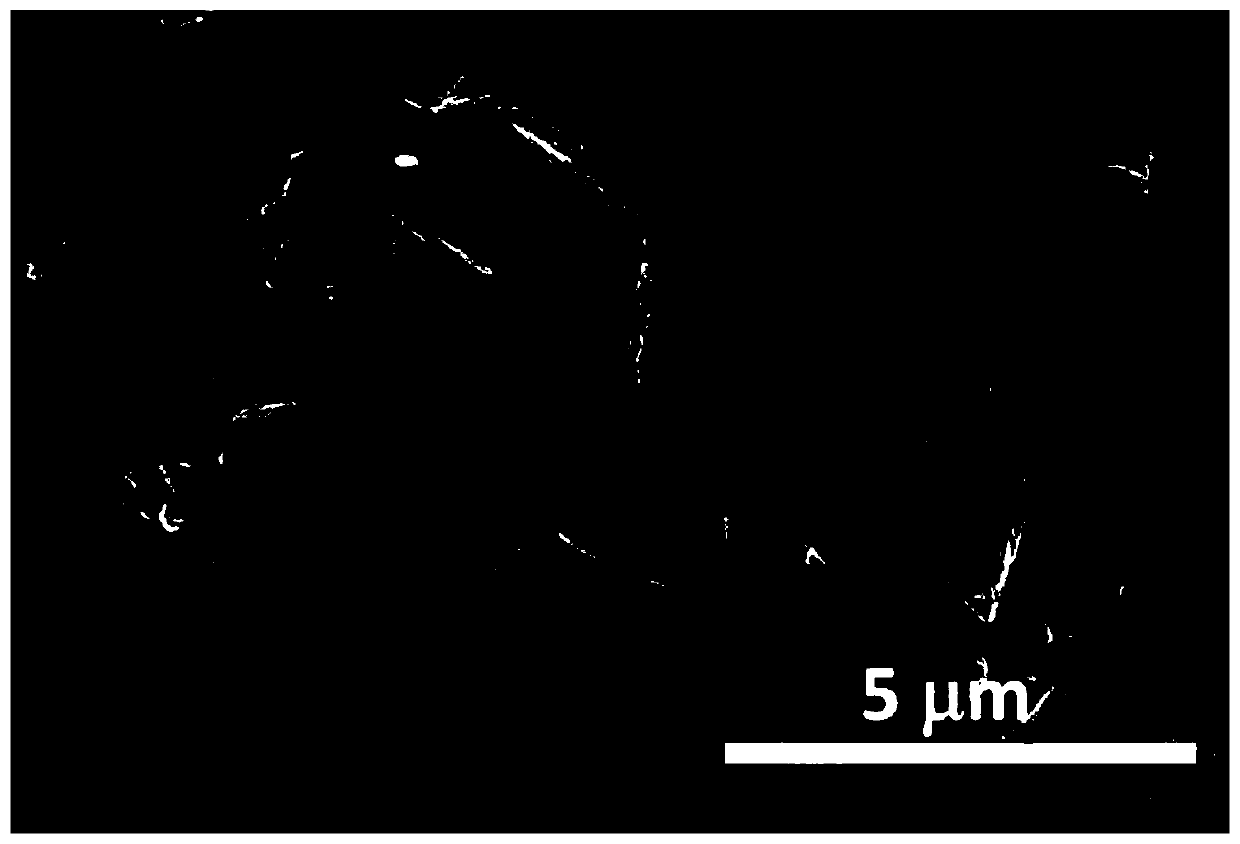

[0038] A preparation method of sulfur-doped MXene negative electrode material includes the following steps:

[0039] (1) Weigh 0.4g of V 2 CT x Place 8g of 2-phenylethanethiol on both ends of the quartz boat, and place the end with 2-phenylethylthiol on the upstream of the tube furnace.

[0040] (2) Under a high-purity argon atmosphere with a gas flow rate of 160ml / min, the temperature is increased from room temperature 20°C at 2.5°C / min to 320°C, kept for 2h, and then cooled to 100°C at 2.5°C / min. Keep it at ℃ for 2h, then lower to room temperature, wash the sample with deionized water after cooling, and vacuum dry to obtain the final sample.

[0041] (3) Preparation of the negative electrode of potassium ion battery: mix the sulfur-doped MXene obtained in step (2) with polyvinylidene fluoride binder and carbon black in a mass ratio of 8:1:1, and add an appropriate amount of N- Methylpyrrolidone is uniformly stirred to form a slurry and coated on the current collector, and after va...

Embodiment 3

[0044] A preparation method of sulfur-doped MXene negative electrode material includes the following steps:

[0045] (1) Weigh 0.5g of V 2 CT x Place 10g of 2-phenylethanethiol on both ends of the quartz boat, and place the end with 2-phenylethylthiol on the upstream of the tube furnace.

[0046] (2) Under a high-purity argon atmosphere with a gas flow rate of 160ml / min, the temperature is increased from 20°C at room temperature to 600°C at 5°C / min and kept for 2h, and then cooled to 100°C at 4°C / min. Keep it at ℃ for 2h, then lower to room temperature, wash the sample with deionized water after cooling, and vacuum dry to obtain the final sample.

[0047] (3) Preparation of the negative electrode of potassium ion battery: mix the sulfur-doped MXene obtained in step (2) with polyvinylidene fluoride binder and carbon black in a mass ratio of 8:1:1, and add an appropriate amount of N- Methylpyrrolidone is uniformly stirred to form a slurry and coated on the current collector, and after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com