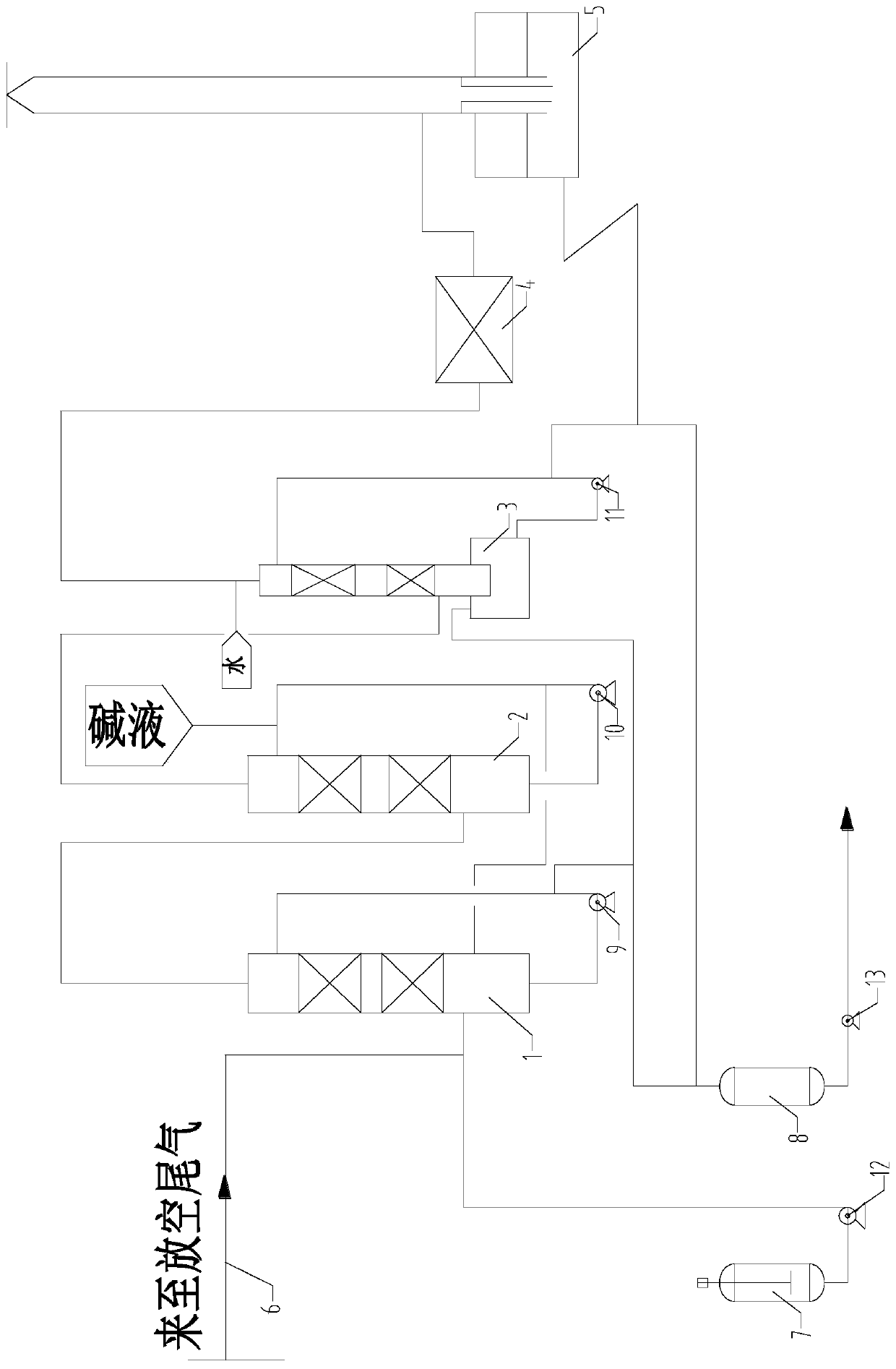

Device and process for absorbing and treating NOx, HF, HCl, caustic soda mist and inert tail gas

A technology of exhaust gas absorption and treatment device, applied in the chemical industry, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of complex composition, inability to remove nitrogen oxides and inert gases, single, etc., and achieve high energy consumption , Reduce the effect of exhaust gas treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The agent and water are configured into a 20% agent through the configuration tank, and the feeding and concentration monitoring of the agent are controlled by PLC, and the prepared agent is mixed with the tail gas from the air pipe into the reduction scrubber, and the reduction scrubber cleans the exhaust gas. Nitrogen oxides are washed and absorbed, and the tail gas from the top of the reduction washing tower enters the alkali washing tower for absorption treatment again, and the untreated gas components such as hydrogen chloride and hydrogen fluoride in the absorption gas are neutralized, absorbed and washed, and the alkali washing tower The part of the liquid discharged from the bottom is recycled and washed, and part of it is cooled and returned to the reduction washing tower as a supplementary washing liquid, making full use of the washing of waste caustic soda and reducing the use of chemicals. The tail gas discharged from the top of the alkali washing tower enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com