Composition and manufacturing method of PVC electrical conduit

A technology of electrical casing and raw materials, applied in the material composition and manufacturing field of PVC electrical casing, which can solve the problems of opaque electrical casing and the inability to clearly understand the internal wires and cables, so as to improve softness and elasticity and facilitate construction , good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

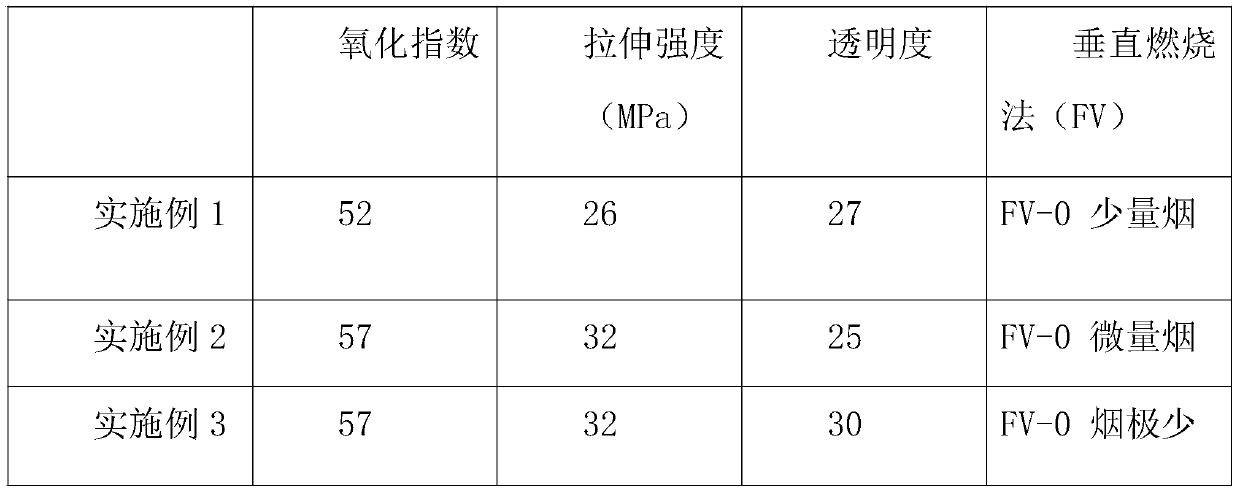

Embodiment 1

[0031] Material composition and manufacturing method of a PVC electrical bushing: The electrical bushing material is composed of the following raw materials: 100 parts of polyvinyl chloride resin, 2-4 parts of stabilizer, 4-6 parts of plasticizer, and reinforcing agent 9-11 parts, 2-4 parts of lubricant, 3-5 parts of processing aid, 0.5-1.5 parts of brightener, 0.05-0.15 parts of organic toner, 3-7 parts of inorganic flame retardant,

[0032] The stabilizer is an organotin stabilizer; the lubricant is divided into internal lubricant and external lubricant, the external lubricant is low molecular polyethylene, the internal lubricant is butyl stearate, and the amount of internal lubricant is greater than that of the external lubricant The plasticizer is dioctyl phthalate; the reinforcing agent is acrylate; the inorganic flame retardant is made of aluminum hydroxide, magnesium hydroxide, red phosphorus, ammonium polyphosphate, zinc borate, antimony oxide and molybdenum Compound c...

Embodiment 2

[0034] Material composition and manufacturing method of a PVC electrical bushing: The electrical bushing material is composed of the following raw materials: 100 parts of polyvinyl chloride resin, 3-5 parts of stabilizer, 5-8 parts of plasticizer, and reinforcing agent 10-12 parts, 2-4 parts of lubricant, 3-5 parts of processing aid, 1.5-2.3 parts of brightener, 0.1-0.2 parts of organic toner, 5-9 parts of inorganic flame retardant,

[0035] The stabilizer is an organotin stabilizer; the lubricant is divided into internal lubricant and external lubricant, the external lubricant is low molecular polyethylene, the internal lubricant is butyl stearate, and the amount of internal lubricant is greater than that of the external lubricant The plasticizer is dioctyl phthalate; the reinforcing agent is acrylate; the inorganic flame retardant is made of aluminum hydroxide, magnesium hydroxide, red phosphorus, ammonium polyphosphate, zinc borate, antimony oxide and molybdenum Compound co...

Embodiment 3

[0037] Material composition and manufacturing method of a PVC electrical bushing: The electrical bushing material is composed of the following raw materials: 100 parts of polyvinyl chloride resin, 3-5 parts of stabilizer, 5-8 parts of plasticizer, and reinforcing agent 10-12 parts, 2-4 parts of lubricant, 3-5 parts of processing aid, 1.5-2.3 parts of brightener, 0.05-0.15 parts of organic toner, 8-11 parts of inorganic flame retardant,

[0038] The stabilizer is an organotin stabilizer; the lubricant is divided into internal lubricant and external lubricant, the external lubricant is low molecular polyethylene, the internal lubricant is butyl stearate, and the amount of internal lubricant is greater than that of the external lubricant The plasticizer is dioctyl phthalate; the reinforcing agent is acrylate; the inorganic flame retardant is made of aluminum hydroxide, magnesium hydroxide, red phosphorus, ammonium polyphosphate, zinc borate, antimony oxide and molybdenum Compound...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap