Three-dimensional Electrode for Removing Iron Ions from Sulfuric Acid Solution by Electrochemical Deposition

A sulfuric acid solution, electrochemical technology, applied in the direction of sulfur trioxide/sulfuric acid, electrodes, optics, etc., can solve the problems that affect the rate of the reaction process, iron removal process efficiency, hydrogen evolution side reaction, etc., to achieve effective removal and mass transfer rate High, the effect of improving speed and current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

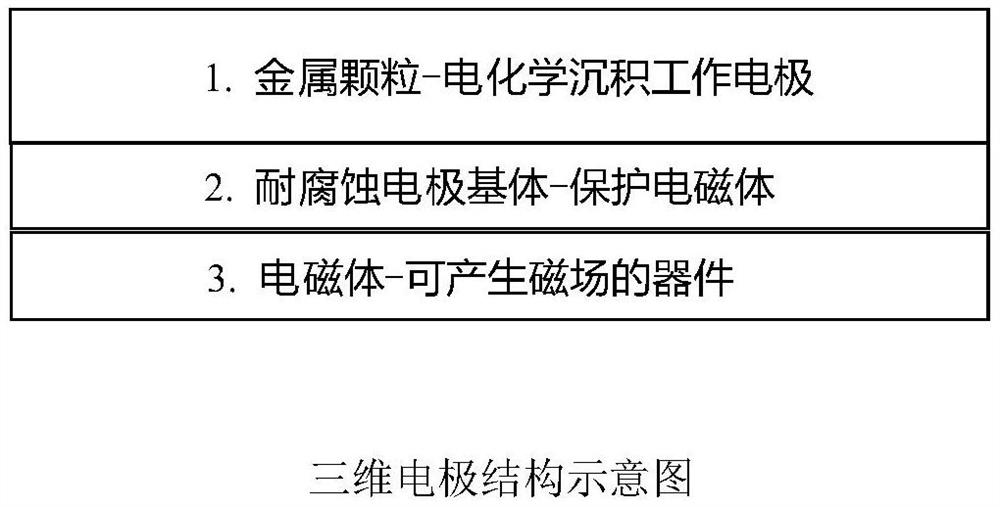

[0036] As shown in the attached figure, a three-dimensional electrode for removing iron ions in sulfuric acid solution by electrochemical deposition, especially a three-dimensional moving bed that uses metal particles with high hydrogen evolution overpotential as electrocatalytic material and whose surface can be renewed as a cathode An electrode characterized by the following:

[0037] (1) Cathode: composed of three-dimensional moving bed electrode, corrosion-resistant electrode substrate and electromagnet;

[0038] (2) Three-dimensional moving bed electrode: lead particles are used as the working electrode of the three-dimensional moving bed electrode. The equivalent diameter of the lead particle is 0.1 mm, and the bed thickness is 10.0 mm. At the lead / electrolyte interface, Fe 2+ An electrochemical reduction reaction occurs to generate Fe, which is deposited on the surface of the lead particles;

[0039] (3) Corrosion-resistant electrode substrate: lead is used as the corr...

Embodiment 2

[0044] As shown in the attached figure, a three-dimensional electrode for removing iron ions in sulfuric acid solution by electrochemical deposition, especially a three-dimensional moving bed that uses metal particles with high hydrogen evolution overpotential as electrocatalytic material and whose surface can be renewed as a cathode An electrode characterized by the following:

[0045] (1) Cathode: composed of three-dimensional moving bed electrode, corrosion-resistant electrode substrate and electromagnet;

[0046] (2) Three-dimensional moving bed electrode: Pb-Cd alloy particles with high hydrogen evolution overpotential are used as the working electrode of the three-dimensional moving bed electrode. The equivalent diameter of the alloy particles is 1.0 mm, and the bed thickness is 20.0 mm. Electrolyte interface, Fe 2+ An electrochemical reduction reaction occurs to generate Fe, which is deposited on the surface of the metal alloy particles;

[0047] (3) Corrosion-resista...

Embodiment 3

[0052] As shown in the attached figure, a three-dimensional electrode for removing iron ions in sulfuric acid solution by electrochemical deposition, especially a three-dimensional moving bed that uses metal particles with high hydrogen evolution overpotential as electrocatalytic material and whose surface can be renewed as a cathode An electrode characterized by the following:

[0053] (1) Cathode: composed of three-dimensional moving bed electrode, corrosion-resistant electrode substrate and electromagnet;

[0054] (2) Three-dimensional moving bed electrode: cadmium particles are used as the working electrode of the three-dimensional moving bed electrode. The equivalent diameter of the cadmium particles is 2.0 mm, and the bed thickness is 50.0 mm. 2+ Electrochemical reduction reaction occurs to generate Fe, which is deposited on the surface of cadmium particles;

[0055] (3) Corrosion-resistant electrode substrate: Metal cadmium on the surface of the electromagnet is used a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com