A kind of moisture-absorbing and quick-drying machine-washable wool worsted fabric and its production method

A technology for moisture-absorbing, quick-drying, worsted fabrics, applied in textile, dyeing, textile and papermaking, etc., can solve the problems of inability to reach wool fibers, restrict the application of wool fibers, and limit the improvement range, and achieve a widened level and scope of application. , Good promotion and application value, reduce the effect of reducing the intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

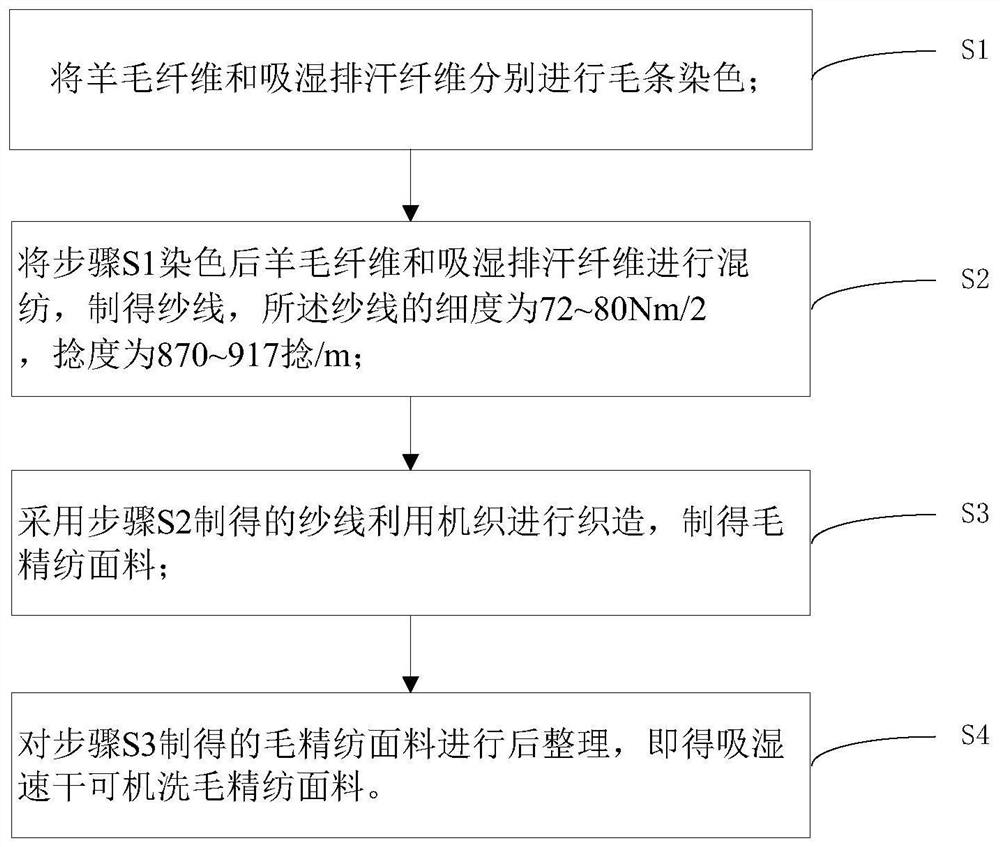

[0061] as attached figure 1 Shown, a kind of production method of moisture-absorbing and quick-drying machine-washable worsted fabric comprises the following steps:

[0062] S1, the wool fiber and the moisture-absorbing and sweat-wicking fiber are respectively carried out top dyeing, the moisture-wicking and sweat-wicking fiber is coolmax fiber, and the coolmax fiber is a polyethylene terephthalate (PET) fiber with a special-shaped section; the weight percentage is as follows: 80% wool fiber, 20% coolmax fiber, the fineness of wool fiber is 16-20μm, and the length is 70-80mm; the fineness of coolmax fiber is 2D, and the length is 70mm;

[0063] Among them, top dyeing includes wool fiber dyeing and moisture-wicking fiber dyeing;

[0064] Wool fiber dyeing involves the following steps:

[0065] 101. Add Lannasol Black CE-R, Abaig B and Yuanmingfen to the dyeing bathtub, adjust the pH value to 4 with acetic acid, and the leveling agent is Abaig B;

[0066] 102. Dip the wool fi...

Embodiment 2

[0096] as attached figure 1 Shown, a kind of production method of moisture-absorbing and quick-drying machine-washable worsted fabric comprises the following steps:

[0097] S1. Dye the wool fiber and the moisture-absorbing and perspiration-wicking fiber respectively. The moisture-absorbing and perspiration-wicking fiber is coolpuls fiber. Coolpuls fiber is a kind of polyester fiber, which is a combination of PET and special polymer. Ten" shape; the weight percentage is as follows: wool fiber 85%, coolpuls fiber 15%; the fineness of wool fiber is 16-20μm, and the length is 70-80mm; the fineness of coolpuls fiber is 3D, and the length is 90mm.

[0098] Among them, top dyeing includes wool fiber dyeing and moisture-wicking fiber dyeing;

[0099] Wool fiber dyeing involves the following steps:

[0100] 101. Add Lannasol Black CE, Abaiger LTD and Yuanming powder into the dyeing bathtub, adjust the pH value to 5 with acetic acid, and the leveling agent is Abaiger B;

[0101] 102...

Embodiment 3

[0131] as attached figure 1 Shown, a kind of production method of moisture-absorbing and quick-drying machine-washable worsted fabric comprises the following steps:

[0132] S1. Dyeing the wool fiber and the moisture-absorbing and sweat-wicking fiber respectively, wherein the percentage by weight is as follows: 82% of the wool fiber and 18% of the moisture-wicking and sweat-wicking fiber, the fineness of the wool is 16-20 μm, and the length is 70-80 mm; The moisture-wicking fiber has a fineness of 2.5D and a length of 80mm.

[0133] Among them, top dyeing includes wool fiber dyeing and moisture-wicking fiber dyeing;

[0134] Wool fiber dyeing involves the following steps:

[0135] 101. Add Lannasol blue CE, leveling agent Abaig B and Yuanming powder into the dyeing bathtub, and adjust the pH value to 4.5 with acetic acid, wherein the leveling agent is Abaig B;

[0136] 102. Dip the wool fiber into the dyeing tub in step 101 at a temperature of 25°C for dyeing, adopt a stage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com