Method for quickly measuring content of 3,4-benzopyrene in coal tar and coal pitch

A technology for rapid determination of coal tar, applied in the field of chemical detection and analysis, can solve problems such as incompatibility, and achieve the effects of less organic solvent consumption, fewer processing steps, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

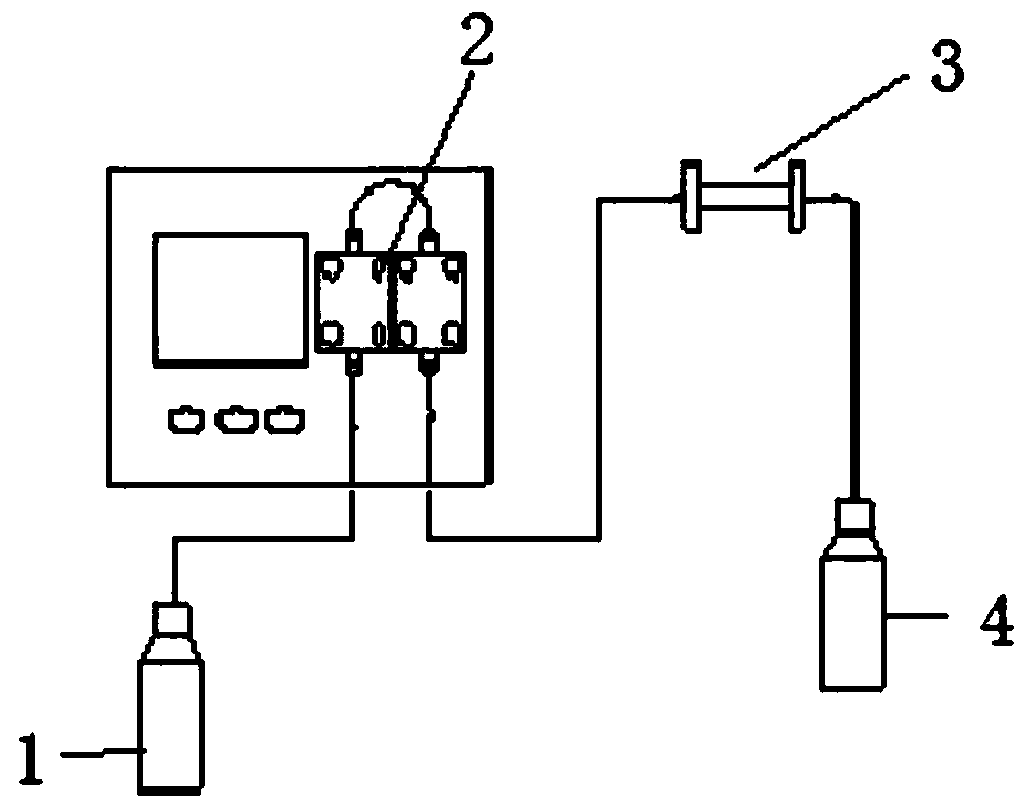

Method used

Image

Examples

Embodiment 1

[0075] Mix the low-temperature coal tar fully and evenly, accurately weigh it to 1.0000g and put it into the extraction column, use acetone as the extraction solvent, control the pressure of the pump in the extraction device to 4Mpa, and the extraction speed to 1mL / min, extract the 3,4 - Dilute the benzopyrene solution to 20ml.

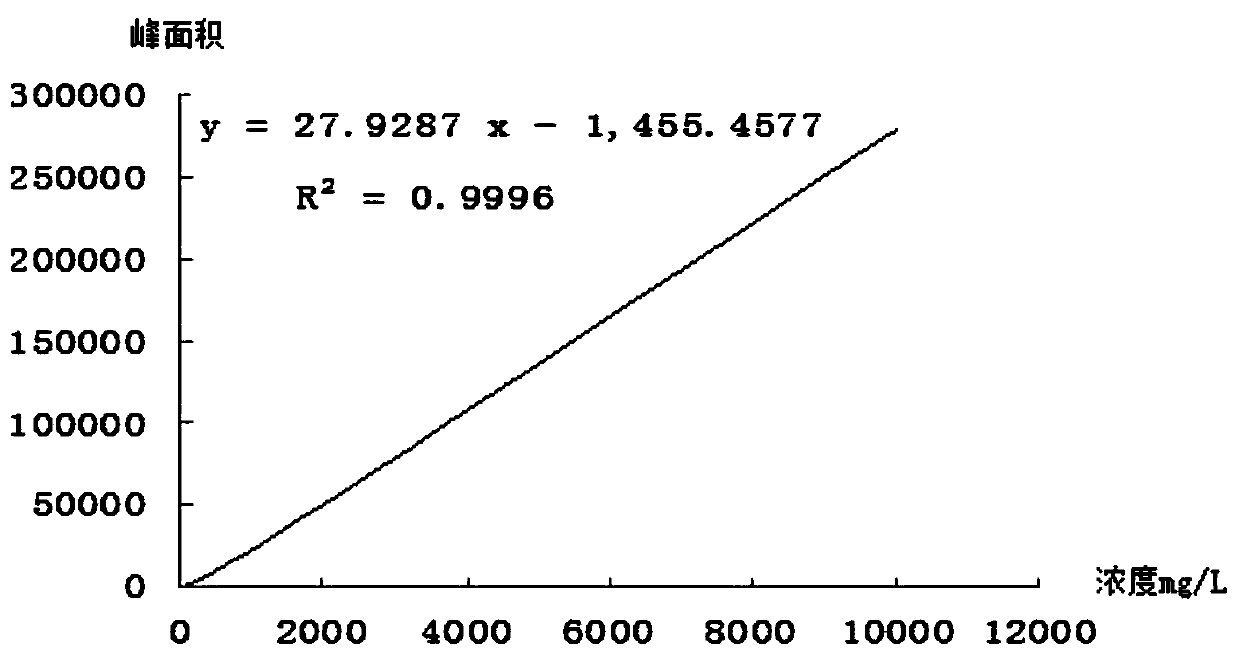

[0076] The 3,4-benzopyrene standard solution of 0.1mg / L, 1mg / L, 10mg / L, 100mg / L, 1000mg / L, and the 3,4-benzopyrene solution after constant volume were analyzed by gas chromatography. The conditions are: the detector adopts a hydrogen flame ionization (FID) detector, and the chromatographic column adopts an SE-54 (30m×0.25mm×0.32μm) gas chromatographic column.

[0077] The temperature programming process is as follows: initial temperature 80°C, retention time 0min, heating rate 8°C / min, final temperature 260°C, retention time 5min; carrier gas is high-purity argon; pre-column pressure 100kpa; injection volume 1μL ; The inlet temperature is 260°C; the ...

Embodiment 2

[0080] Slowly heat the coal tar pitch with a softening point of 45°C to a liquid state in an oil bath and mix well, accurately weigh 0.5000g and put it into the extraction column, use acetone as the extraction solvent, the pressure of the pump in the extraction device is 3Mpa, the extraction speed 0.8mL / min, the extracted 3,4-benzopyrene solution was adjusted to 20ml.

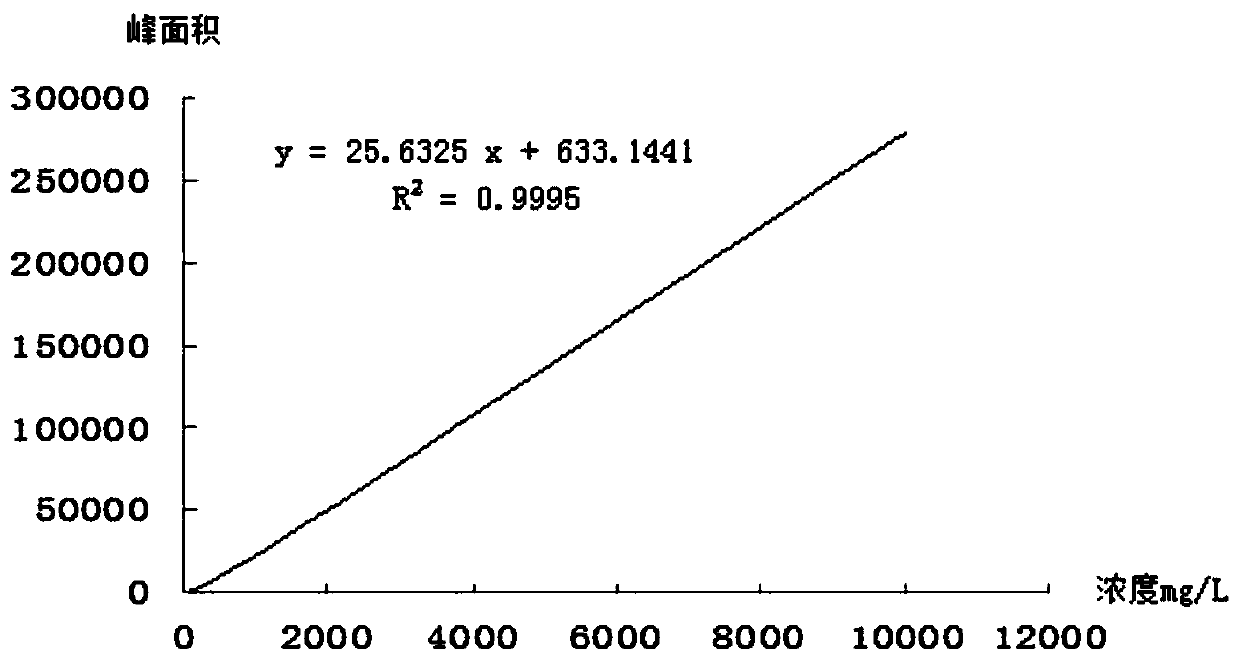

[0081] The 10mg / L, 100mg / L, 1000mg / L, 10000mg / L 3,4-benzopyrene standard solution and the 3,4-benzopyrene solution after constant volume were analyzed by gas chromatography, and the chromatographic conditions were: detector A hydrogen flame ionization (FID) detector is used; the chromatographic column is SE-54 (50m×0.25mm×0.32μm) gas chromatographic column.

[0082] The temperature programming process is: initial temperature 100°C, retention time 2min, heating rate 5°C / min, final temperature 275°C, retention time 10min; carrier gas is high-purity argon; column pre-pressure is 120kpa; injection volume is 0.5 μL...

Embodiment 3

[0085] Crush the imported high-temperature asphalt with a softening point of 230°C, grind it in a mortar, and sieve it with a 200-mesh sieve until it is completely sieved; accurately weigh 0.5000g and put it into the extraction column, using cyclohexane as the extraction solvent , the pressure of the pump in the extraction device was 6Mpa, the extraction speed was 0.8mL / min, and the volume of the extracted 3,4-benzopyrene solution was adjusted to 20ml.

[0086] The 3,4-benzopyrene standard solution of 0.1mg / L, 1mg / L, 10mg / L, 100mg / L, 1000mg / L, and the 3,4-benzopyrene solution after constant volume were analyzed by gas chromatography. The conditions are: the detector adopts a hydrogen flame ionization (FID) detector; the chromatographic column adopts a SE-54 (50m×0.25mm×0.32μm) gas chromatographic column.

[0087] The temperature programming process is as follows: initial temperature 120°C, retention time 3min, heating rate 10°C / min, final temperature 320°C, retention time 15mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com