Self-heated battery based on carbon nanotube film and method for fabricating same

A carbon nanotube film and carbon nanotube technology are applied in the field of self-heating batteries based on carbon nanotube films and their preparation, and can solve the problems of poor temperature control detection accuracy, damage to batteries and diaphragms, and complex self-heating systems. , to achieve the effect of high heating efficiency, uniform heating, and high heat energy conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

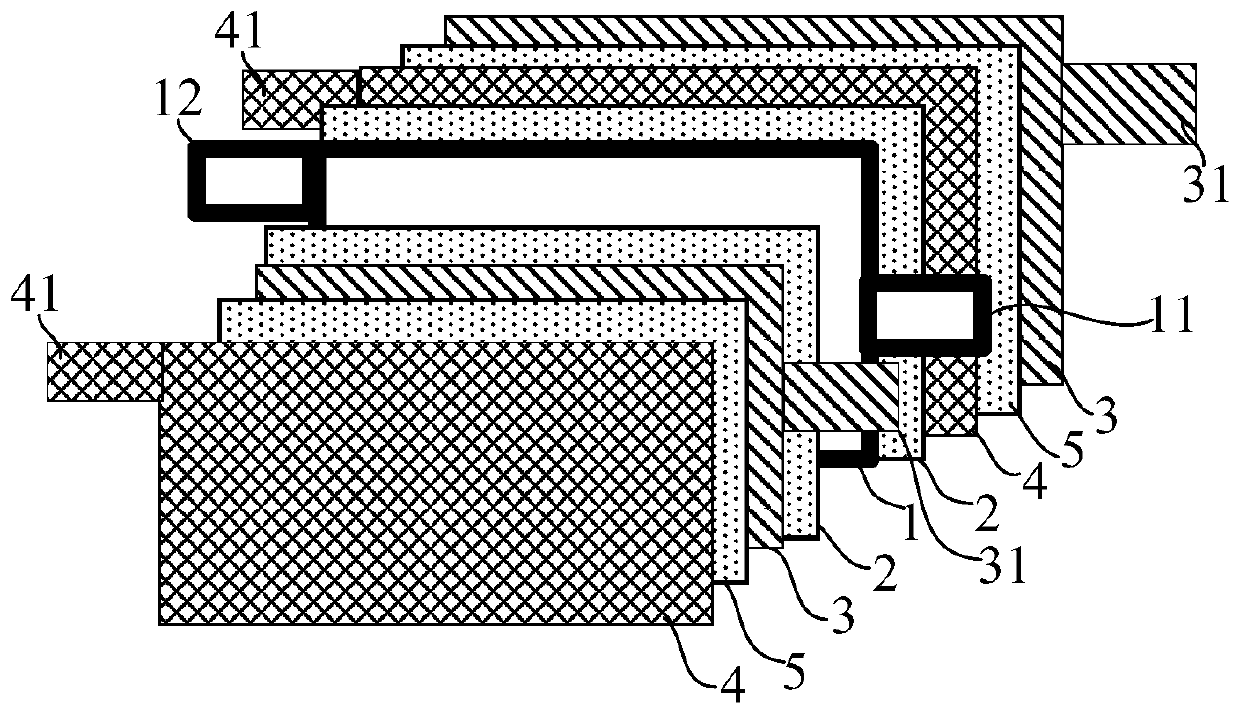

[0046] An implementation, such as figure 1 As shown, the self-heating battery can include two groups of pole pieces, each group of pole pieces is separated by a flexible carbon nanotube film 1 and the first diaphragm 2, and each group of pole pieces includes a positive pole piece 3, a negative pole piece 4, a separator Open the second diaphragm 5 of the positive and negative plates and the electrolyte ( figure 1 not shown). The positive electrode sheet 3 is provided with a positive electrode tab 31, the negative electrode sheet 4 is provided with a negative electrode tab 41, the positive electrode tab 31 and the negative electrode tab 41 are located on different sides of the battery, and the flexible carbon nanotube film 1 is correspondingly provided with the positive electrode tab 31. The first tab 11 on the same side and the second tab 12 on the same side as the negative tab 41 .

[0047] In the present disclosure, the electrolyte is well known to those skilled in the art....

Embodiment 1

[0063] Preparation of flexible carbon nanotube film: take a certain amount of ferrocene (control concentration 2mg / mL) and thiophene (control concentration 3μL / mL -1 ) into a mixed solution of methanol and n-hexane (volume ratio 9:1), and ultrasonically disperse for 10 min to make the solution evenly mixed. Assemble the quartz tube, collector and reaction furnace, and seal the reaction chamber; -1 Raise the temperature of the high-temperature resistance furnace to the reaction temperature of 1200°C at a rate of 1200°C, and pass the reaction solution into the reaction high-temperature zone through a peristaltic pump under an argon atmosphere (flow rate 30mL·h -1 ); After 20 minutes of reaction, the carbon nanotube macroscopic body can be seen to be generated from the quartz tube mouth. Then, the ethanol aqueous solution with a volume fraction of 20% is sprayed on the surface of the substrate; then, the carbon nanotube macroscopic body generated from the reactor port is adhered...

Embodiment 2

[0070] It is basically the same as Example 1, except that the thickness of the high-strength flexible carbon nanotube film is controlled to be 20 μm, and the surface density is 0.8 mg / cm 2 .

[0071] The heating time of the performance test is 5 minutes, and the capacity retention rate is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com