Plant-based smearing-type walnut cheese and preparation method thereof

A spread-type, plant-based technology, applied in the field of plant-based spread-type walnut cheese and its preparation, can solve the problems of high nutrient loss rate of cheese, low walnut content, and high cost of processed walnut cheese, and achieve rich varieties and good taste. , good flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

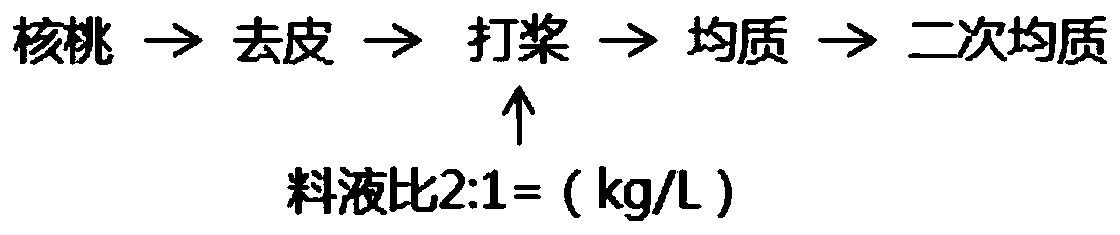

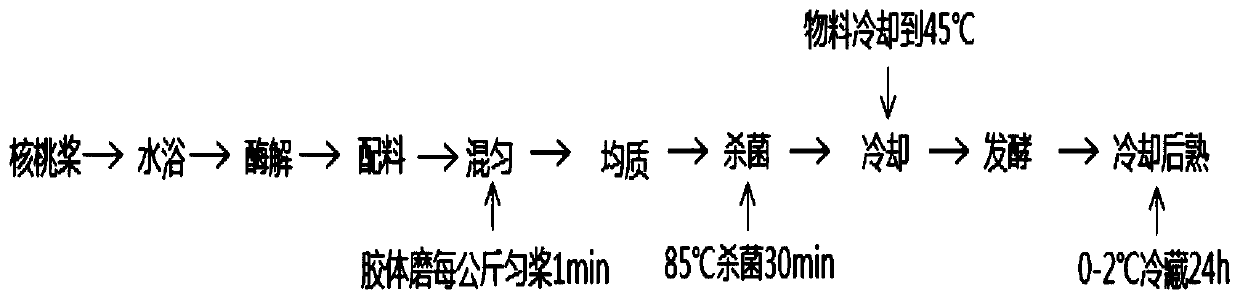

[0036] Such as figure 1 As shown, the plant-based spreadable walnut cheese process is as follows:

[0037] Peeling: After shelling the fresh dried walnuts, pick out the shriveled kernels, bad kernels, impurities, etc. in the walnut kernels, freeze them at -20°C overnight, soak them in warm water at 60°C at room temperature for 30 minutes, and wash them with a high-pressure water gun Remove the seed coat, and select the peeled walnut kernels for later use.

[0038] Beating: Utilize 80-120 mesh colloid mill to refine the walnut kernel, and 1kg of it is circulated and refined for 5 minutes for later use.

[0039] Homogenization: The walnut pulp is homogenized by secondary homogenization. First, use a homogenizer with a maximum homogenization pressure of 25MPa to homogenize the walnut pulp once at 5-6MPa; then use a homogenizer with a maximum homogenization pressure of 60MPa The machine and 25-35MPa perform secondary homogenization on the primary homogenized walnut paddle. in, ...

Embodiment 2

[0050] The present embodiment is the screening test of enzyme additives and the screening of casease hydrolysis parameters, as follows:

[0051] Taking walnut paddle enzymatic hydrolyzate sensory score and free amino acid content as indicators, after passing through 0.15% lipase enzymolysis, through protease enzymolysis, investigate flavor protease, compound protease enzyme addition amount (0.1, 0.15, 0.2, 0.25, 0.3 %), enzymatic hydrolysis time (30, 50, 70, 90, 110min) on the sensory evaluation of the enzymolyzed solution, the impact of free amino acid content, the results are shown in the table below.

[0052] Table 1 Effects of various enzyme additives on the sensory score and free amino acid content of the enzymatic hydrolyzate

[0053]

[0054] It can be seen from the above table: when the addition of flavor protease is 0.15%, and the enzymolysis time is 70 minutes, the sensory score and free amino acid content of the enzymolysis solution are the highest; And the high...

Embodiment 3

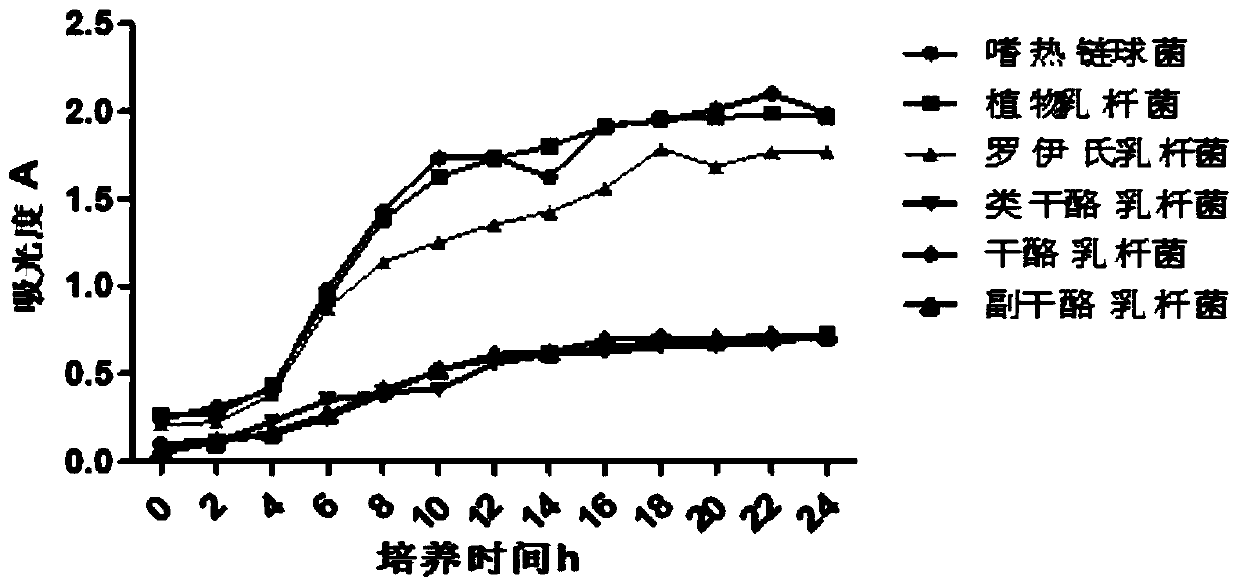

[0056] Present embodiment is the screening test of microbial compound bacterial agent, as follows:

[0057] Strains: Bifidobacterium infantis CICC 6069, Lactobacillus plantarum CICC 6002, Lactobacillus fermentium CICC6233, Lactobacillus helveticus CICC 6064, Lactobacillus johnsonii CICC 6084), Lactobacillus reuteri CICC 6226, Lactobacillus paracasei CICC 20252, Lactobacillus caseiBNCC134415, Lactobacillus paracasei BNCC192210, Streptococcus thermophilus thermophilus CICC 20370).

[0058] (1) Activation of bacteria

[0059] The probiotics preserved in the laboratory were respectively inoculated into MRS broth, and cultured at 37°C for 24 hours to obtain the first-generation strain. The above steps were repeated for 18 hours at constant temperature and humidity at 37°C, and the third activation was performed to obtain a third-generation activated strain, which was stored in a refrigerator at 4°C for later use.

[0060] (2) Strain screening

[0061] The strains were screened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com